Operation Manual

4

XR5519

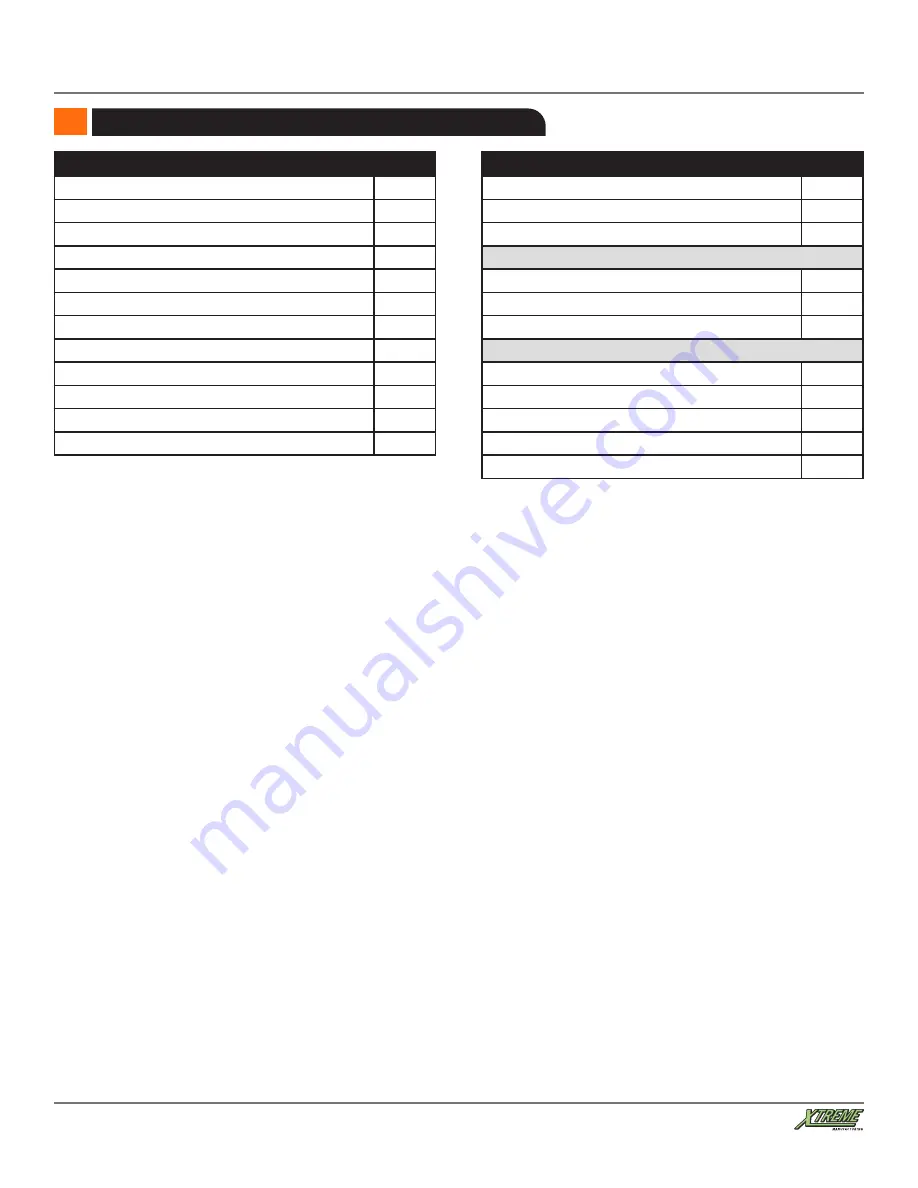

Table of Contents

Table of Contents

Description

Page

Fuel Types

57

Winter Operation With Diesel Fuel

57

Attachments

58

Attachment Disclaimer

58

Fork Ratings

58

Standard Carriage Operation

59

Quick Attach System

59

Load Handling

62

Boom Lift Point

63

Suspended Loads

63

Pick Up a Load

63

Carry a Load

64

Description

Page

Place a Load

64

Load Shift

64

Load Capacity Charts

64

Preventive Maintenance

Establishing a Maintenance Program

66

Maintenance Schedule

66

Boom Emergency Lower Down Valve

68

Lockout / Tagout

Do Not Operate - Accident Prevention Tags

70

New or Additional Operators

70

Lockout/Tagout Procedure

70

Do Not Operate Tags

71

Warranty

72