ASSEMBLY and OPERATION

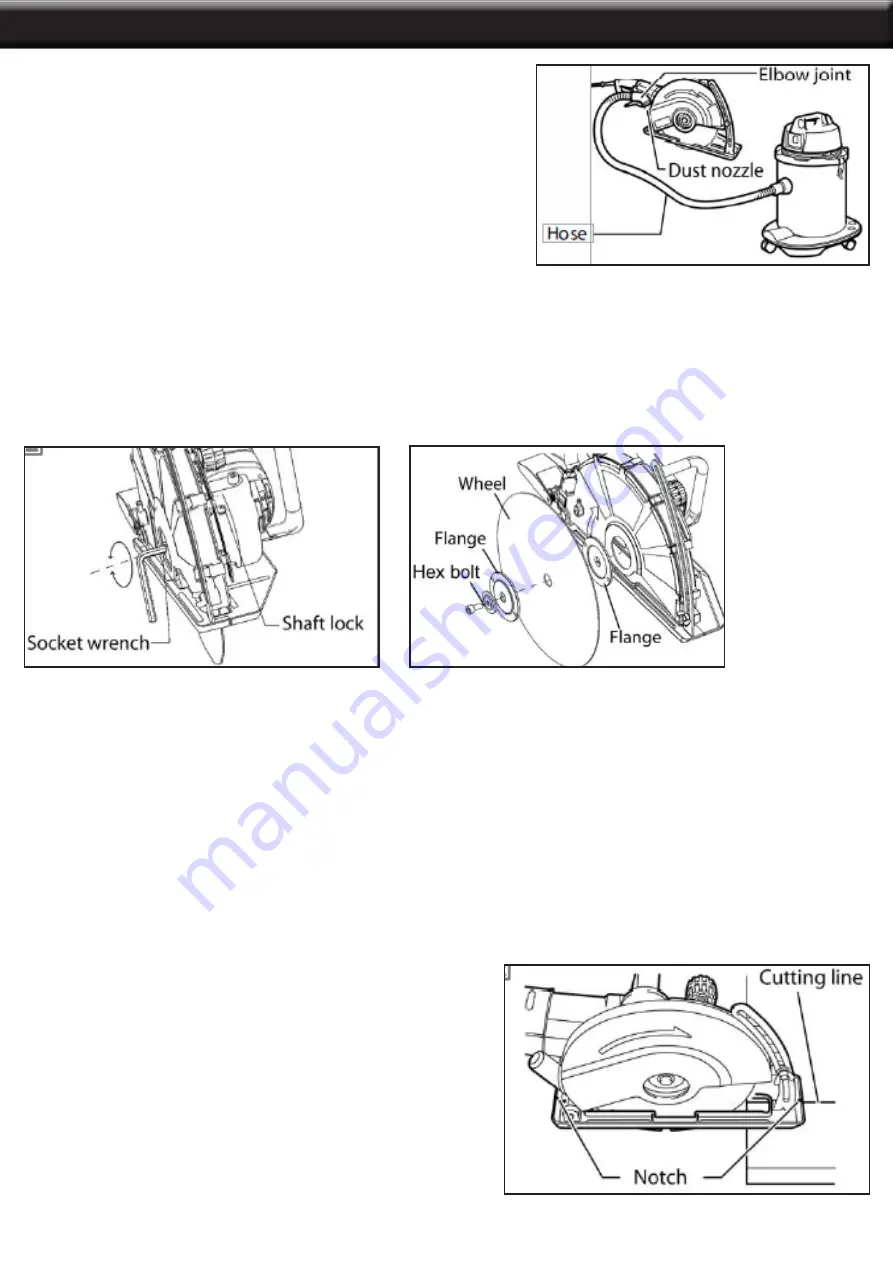

CONNECTING TO VACUUM CLEANER

When you wish to perform cleaner operation, connect a vacuum

cleaner to your tool. Connect a hose of vacuum cleaner to the

dust nozzle via an elbow joint (accessory).

INSTALLING OR REMOVING THE WHEEL

To remove the wheel, depress the shaft lock to hold the shaft stationary, then loosen the

hex bolt clockwise with the socket wrench. To install a wheel, place flange with its partly

elevated side facing the tool, and then place ring before installing a wheel onto the spindle

(shaft) and another flange with partly elevated side facing outward. Be sure to fully tighten the hex bolt

counterclockwise after mounting the new wheel, or operation will be dangerous.

OPERATION

CAUTION:

Be sure to pull the tool when cutting a workpiece.

• This tool should only be used on horizontal surfaces.

• Use this tool for straight line cutting only. Cutting curves can cause stress cracks or fragmentation of the

diamond wheel and abrasive cut-off wheel resulting in possible injury to persons in the vicinity.

• After operation, always switch off the tool and wait until the wheel has come to a complete stop before

putting the tool down.

• When cutting concrete blocks, tiles or masonry materials, do not make a cut in depth more than

60 mm (2-3/B”). When you need to cut a workpiece over 60 mm (2-3/8”) up to 100 mm (4”), make more than

two passes of cuts. The depth of the most efficient cut is about 40 mm (1-9/16”).

Hold the tool firmly with both hands. First keep the wheel

without making any contact with a workpiece to be cut. Then

turn the tool on and wait until the wheel attains full speed.

The cut is made by pulling the tool toward you (not

by pushing away from you). Align the notch on the

base with your cutting line when performing a cut.

Switch off the tool on the position posed when finishing a

cut. Raise the tool after the wheel comes to a complete stop.

5