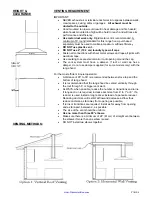

HEIGHT &

CLEARANCE

VENTING REQUIREMENT

IMPORTANT:

•

NEVER exhaust air or terminate duct work into spaces between walls,

crawl spaces, ceiling, attics or garages.

All exhaust must be

ducted to the outside.

•

Hood mounted too low could result in heat damage and fire hazard;

while hoods mounted too high will be hard to reach and will loose its

performance and efficiency.

•

Use metal duct work only

. Rigid metal vent is recommended. A

minimum of 6” round (standard for this range hood, purchased

separately must be used to maintain maximum airflow efficiency

•

DO NOT use plastic vent.

•

DO NOT use 4” (10.2 cm) laundry-type wall caps

•

Fasten all connections with sheet metal screws and tape all joints with

aluminum tape.

•

Use caulking to seal exterior wall or roof opening around the cap.

•

The vent system must have a damper. If roof or wall cap has a

damper, do not use damper supplied (for some models only) with the

range hood.

For the most efficient & quiet operation:

•

A distance of 26” to 30” is recommended between stove top and the

bottom of range hood.

•

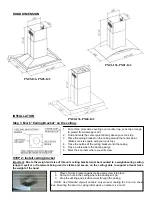

It is recommended that the range hood be vented vertically through

the roof through 6” or bigger vent work.

•

ALWAYS, when possible, reduce the number or transitions and turns.

If long duct run is required, increase duct size from 6” to 7” or 8”. If a

reducer is used, install a long reducer instead of a pancake reducer.

Reducing duct size will restrict airflow and decrease airflow, thus

reduce duct size as far away from opening as possible.

•

If turns or transitions are required: Install as far away from opening

and as far apart, between 2, as possible.

•

The size of the vent should be uniform.

•

Use no more than three 90° elbows.

•

Make sure there is a minimum of 24” (61 cm) of straight vent between

the elbows if more than one elbow is used.

•

DO NOT install two elbows together.

VENTING METHODS:

www.XtremeAirUsa.com

PAGE

4