www.XtremeAirUsa.com

PAGE

4

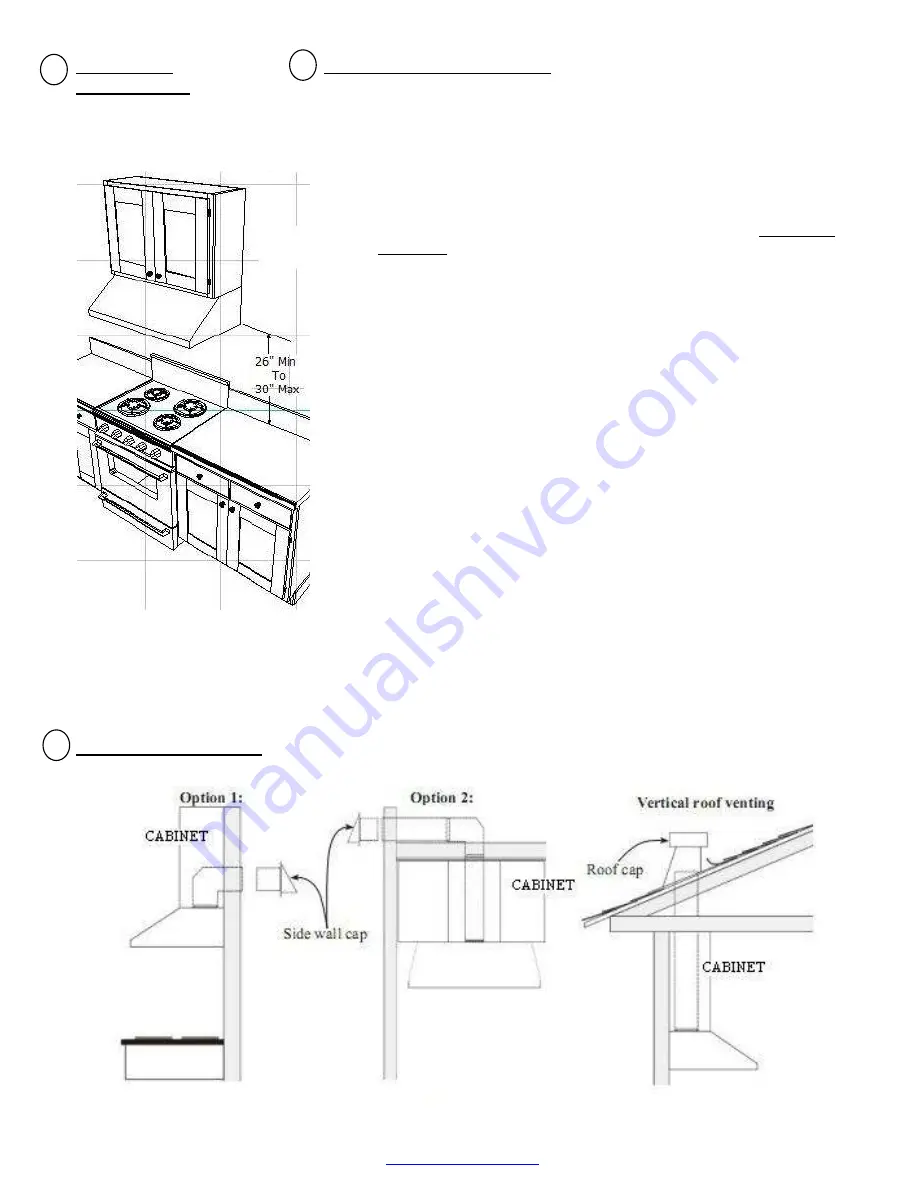

HEIGHT &

CLEARANCE

VENTING METHODS:

VENTING REQUIREMENT

IMPORTANT:

•

NEVER exhaust air or terminate duct work into spaces between walls, crawl

spaces, ceiling, attics or garages.

All exhaust must be ducted to the

outside.

•

Hood mounted too low could result in heat damage and fire hazard; while

hoods mounted too high will be hard to reach and will loose its performance

and efficiency.

•

Use metal duct work only

. Rigid metal vent is recommended. A minimum

of 8” round (standard for this range hood, purchased separately must be used

to maintain maximum airflow efficiency

•

DO NOT use plastic vent.

•

DO NOT use 4” (10.2 cm) laundry-type wall caps

•

Fasten all connections with sheet metal screws and tape all joints with

aluminum tape.

1.

Use caulking to seal exterior wall or roof opening around the cap.

2.

The vent system must have a damper. If roof or wall cap has a damper, do

not use damper supplied (for some models only) with the range hood.

For the most efficient & quiet operation:

•

A distance of 26” to 30” is recommended between stove top and the bottom

of range hood.

•

It is recommended that the range hood be vented vertically through the roof

through 6” or bigger vent work.

•

ALWAYS, when possible, reduce the number or transitions and turns. If

long duct run is required, increase duct size from 8” to 9” or 10”. If a reducer

is used, install a long reducer instead of a pancake reducer. Reducing duct

size will restrict airflow and decrease airflow, thus reduce duct size as far

away from opening as possible.

•

If turns or transitions are required: Install as far away from opening and as

far apart, between 2, as possible.

•

The size of the vent should be uniform.

•

Use no more than three 90° elbows.

•

Make sure there is a minimum of 24” (61 cm) of straight vent between the

elbows if more than one elbow is used.

•

DO NOT install two elbows together.

02

03

04

Summary of Contents for Pro-X Series

Page 14: ...www XtremeAirUsa com PAGE 14 ...