MINI TRACKED DUMPER

21

GB

PARTS LIST

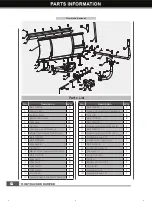

No.

Description

Q'ty

1

Tensioner Pulley Cable

1

2

Safety Control Handle

1

3

Screw M6x16

1

4

Screw M5x20

2

5

Nut M5

2

6

Handle Sleeve

2

7

Throttle Cable

1

8

Throttle Lever

1

9

HOOP

1

10

ON/OFF Switch

1

11

Handle Frame Assembly

1

12

Lower Handle

2

13

Washer ø6

11

14

Screw M6x35

1

15

Screw M6x60

1

16

Right/Left Steering Lever Cable

2

17

Screw M10x20

8

18

Washer10

26

19

Washer10

22

20

Bolt M8X16

6

21

Washer 8

41

22

Soleplate (left)

1

23

Bolt M8x25

11

24

Washer 8

7

25

Handle Mounting Frame

1

26

Bolt M8x20

3

27

Soleplate (right)

1

28

Belt B32

1

29

Pulley Cover Weldment

1

30

Lever Knob

1

31

Lock Nut M10

11

32

Screw M8x20 w/glue

12

33

Bolt M10x70

1

34

Brake Cable

1

35

Driving Wheel

2

36

Nut M8

25

37

Tensioner Pulley Bracket

1

38

Engine

1

No.

Description

Q'ty

39

Key 5x35

1

40

Belt Protect Frame

1

41

Bolt M8x30

3

42

Fixed Bracket

1

43

Washer 8

2

44

Bolt M10x60

2

45

Belt Pulley

1

46

Screw M5x12

1

47

Tensioner Pulley

1

48

Circlip 15

1

49

Bearing 6202-2RS

2

50

Gear Box

1

51

Circlip 35

1

52

Large Belt Pulley Cover

1

53

Nut M6

3

54

Bolt M6x20

1

55

Wheel Axle Press Board

2

56

Support Plate (right)

1

57

Belt Plate

1

58

Connecting Angle Block

1

59

Bolt M6x25

2

60

Bolt M8x40

4

61

Bolt M10x65 w/glue

8

62

Nut M8

14

63

Cable Fixing Base

1

64

Rubber Mat

2

65

Support Plate (left)

1

66

Long Extension Spring

1

67

Skeleton Oil Seal

4

68

Weight Supporting Wheel Weldment

4

69

Bearing 6204-2RS

8

70

Washer 10

6

71

Bolt M10x25

6

72

Axle Head Cover(47)

4

73

Track 180x60

2

74

Axle Head Cover(42)

2

75

Circlip 42

8

76

Bear 61905-2RS

4

09715UK00M112_更新回收处理标志_未发排.indd 21

2020/6/29 16:19:42

MINI TRACKED DUMPER

22

GB

No.

Description

Q'ty

77

Guiding Wheel

2

78

Sealing Ring30X42X7

2

79

Nut M16

2

80

Bolt M16x110

2

81

Underframe Weldment

1

82

Guide Wheel Axle

1

83

Bolt M10X20

4

84

Support Bracket

1

85

Flat Gasket 16

2

86

Plain Shaft

1

87

Pin 4X35

2

88

Dumper Box

1

89

Operation Lever Frame

1

90

Handle Frame Weldment

1

91

Nut M12

1

92

Washer 12

2

93

Extension Spring

2

94

Handle Sleeve

1

95

Guiding Spring

2

96

Locating sleeve

2

97

Bolt M8X35

4

98

Pin 5x30

1

99

Gearshift Lever

1

100

Pin 3*30

1

101

Bolt M8*12 w/glue

1

102

Orientation Nut

1

103

Washer GroupwareD20

1

104

O-Ring 11.2x1.8

1

105

Lever Mount Bracket

1

106

Seal F B17X40X7

2

107

Spline Shaft II

1

108

Duplex Slip Gear

1

109

Gear

1

110

Bearing 6302

1

111

Gearshift Fork Guide Pin

1

112

Spring

1

113

Steel Ball 6

1

114

Gearshift Fork

1

No.

Description

Q'ty

115

Circlip 12

1

116

Rivet Assembly

1

117

Brake Disk

1

118

Joint Bolt

3

119

Plate

1

120

Brake Pull Plate

1

121

Washer6

4

122

Washer6

2

123

Bolt M6x16

4

124

Expansion Brake Cover

1

125

Stud

1

126

Vent-Plug Bushing

1

127

Vent-Plug

1

128

Screw M8X30

3

129

Expansion Brake Lock Bolt

3

130

Screw M8X130

6

131

Clutch Fork Shaft (L)

1

132

Bolt M6X20

3

133

Swing Plate

2

134

Gear III-4

1

135

Gear III-3

1

136

Large Belt Pulley

1

137

Bearing 6303

5

138

Gear II-5

1

139

Gear II-4

1

140

Gear II-3

1

141

Gear II-2

1

142

Gear III-2 Bush

1

143

Gear III-2

1

144

Gear Shaft III

1

145

Gear Box Case ( L)

1

146

Plug M14x1.5

2

147

Washer Groupware 14

2

148

Gear Box Case

1

149

Output Shaft

2

150

Gear II-1

1

151

Bush 2

1

152

Bush 1

1

09715UK00M112_更新回收处理标志_未发排.indd 22

2020/6/29 16:19:42

Summary of Contents for 196CC/635HP

Page 1: ......

Page 20: ...MINI TRACKED DUMPER 20 GB Gearbox 50 09715UK00M112_更新回收处理标志_未发排 indd 20 2020 6 29 16 19 41 ...

Page 25: ......