17

Version 1 – GBR (25/10/2022)

D-502-0287

Fig. 9

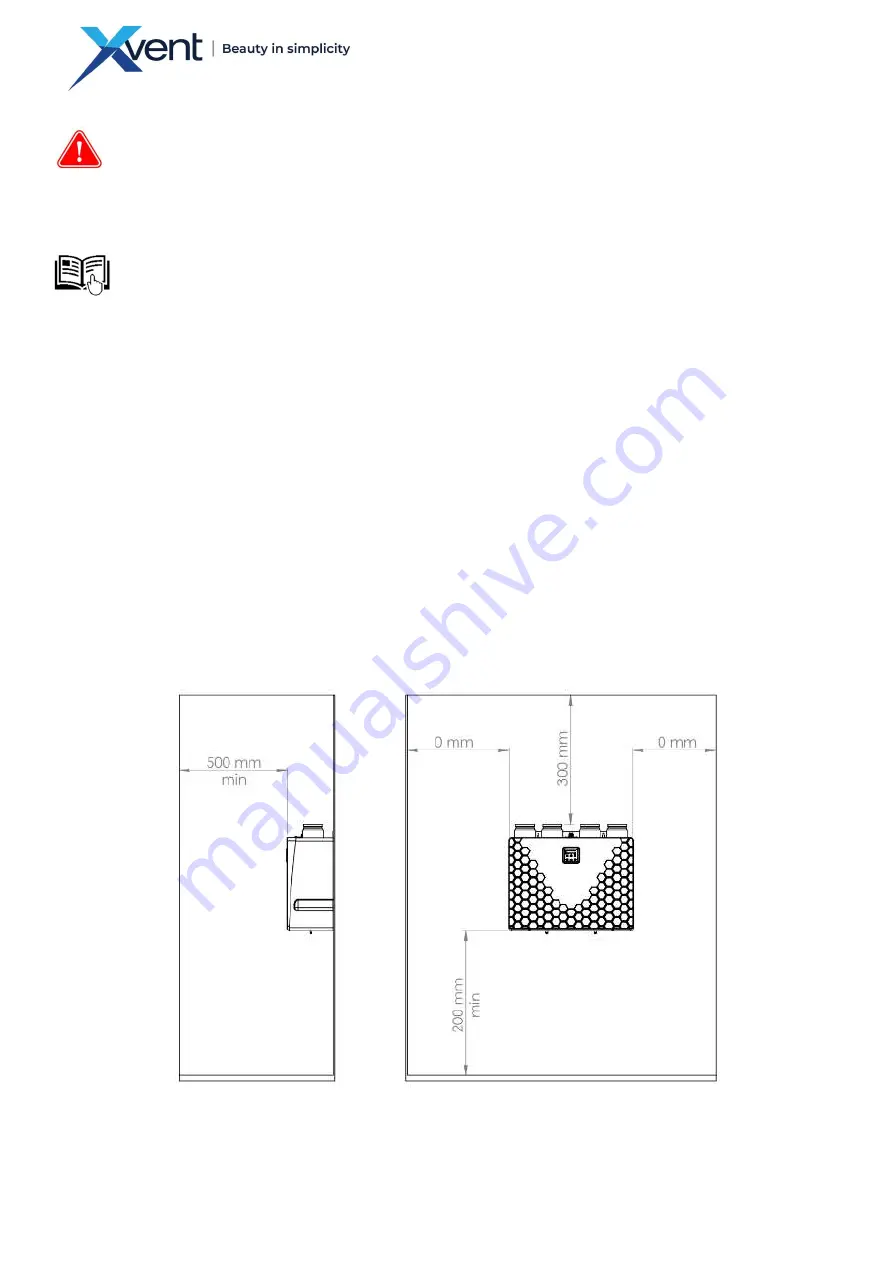

3.1.3.

Unit Location

-

When selecting a location for the installation of the unit, always consider the layout of the building

within the overall HVAC system (e.g.: location of dampers, supply and exhaust ducts, etc.). Consult an

HVAC designer or a person knowledgeable in the field for the proper design of the entire HVAC system.

The manufacturer is in no way responsible for the design of the ventilation system.

-

The unit is to be installed in indoor covered and dry areas with a room temperature of +5 °C to +30 °C and

with maximum relative humidity of 70% non-condensing.

-

Consider the location of the unit indoor away from surrounding objects in relation to the recommended

clearances from the unit (e.g.: filter changes, opening the unit - servicing) as given in chapter 3.1.4.

Minimum installation distances

-

Check your options for connecting the condensate outlet to the waste piping.

3.1.3.1.

Location and operation of the unit in the area with a furnace (fire place)

-

If the air ducts are located in rooms with a furnace, you can set the fan distribution in the customer menu

(more air is supplied than exhausted). The fan balancing cannot replace the separate air supply to the

heater in any way due to the possibility of controlling by AQS sensors.

-

For proper operation of the furnace and the unit, consult the location with the chimney sweep. Otherwise,

the unit may malfunction.

3.1.3.2.

Unit Location and Operation in the Area with an Air Conditioning Unit

-

When operating the unit during the summer months and using the air conditioner in a ventilated area,

condensation may form inside the unit in the opposite supply branch. In this case, it is necessary to connect

a siphon and subsequent condensate drain to the supply branch.

-

The unit is equipped with a plugged outlet for siphon connection as standard. For more information see

Chapter 3.2.3.

-

For trouble-free operation, we recommend installing a unit equipped with an enthalpy exchanger (XH1-

030-ECS0ER...).

3.1.4.

Minimum installation distances

-

Distances from fixed objects:

-

The unit must be installed in such a way that the direction of air flow through the unit itself is the same as

the air flow in the air handling system.

-

Failure to observe the specified clearances may not work properly and may damage the fan, increase noise,

or prevent service access to the unit.