NOTICE:

• Never operate the pump with discharge valve closed for longer

than a few seconds.

• Do not expose an idle pump to freezing conditions. Drain all liq-

uid that is inside the pump. Failure to do so can cause liquid to

freeze and damage the pump.

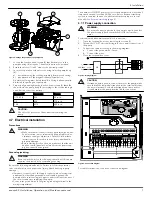

• The suction plus shut-off discharge pressure must not exceed the

pump pressure rating.

• Do not use the pump if cavitation occurs. Cavitation can damage

the internal components.

6.1 Configure the pump settings

Change the pump settings using one of the following methods:

• User interface

• Bus communication

• Wireless communication

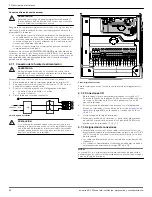

6.1.1 Change the communication parameters

Change pump communication parameters. See

1.

Switch off the pump.

Wait until the power indicator light turns off.

2.

Switch on the pump.

3.

When the display shows COMM, press the parameter button (3) to

access the communication menu.

4.

Select one of the four below parameters using the settings button

(5).

• BAUD = baud rate setup (available values 4.8 - 9.6 - 14.4 -

19.2 - 38.4 - 56.0 - 57.6 kbps)

• PROT = communication protocol (available protocols “mod”

= Modbus; “bac” = BACnet

• ADDR = address setup (available address 1-247 for Modbus

0–127 for BACnet)

• MODU = optional module setup (“none” = no module; “wifi”

= Wireless module; “485” = RS-485 module)

5.

Press the parameter button to enter the submenu

6.

Edit the values using setting buttons.

7.

Press the parameter button to confirm and store the new values.

8.

Press mode button to exit the submenu.

9.

Repeat above procedure for each of the three parameters.

If no buttons are pressed for 10 seconds, then the pump exits the cur-

rent menu and continues start-up procedure. All the parameters that

are changed but not confirmed restore back to previous state.

NOTE: The communication setup menu is available only on display and

not through communication bus.

6.1.2 Change the control mode

The pump can be controlled by a BMS (Building management system)

or other devices through the RS-485 communication port via Modbus

or BACnet protocol.

The following instructions are used when making the change on the

user interface. See

(page 8).

• Press the operating mode button (1).

• The operating modes are cyclically changed by the pressed but-

ton.

mode

mode

mode

mode

mode

mode

6.1.3 Change the set point

1.

Press one of the arrow setting buttons (5).

The display starts to blink.

2.

Change the value using the buttons (5).

3.

Wait 3 seconds to store and activate the new set point.

The display will stop blinking to confirm the change.

NOTICE:

If a check valve is installed on the system, ensure that the pump head is

sufficient to allow flow through the system.

6.1.4 Change the displayed unit of measurement

Power, Flow, Head and Speed parameters cyclically change by press-

ing the parameter button (3). In order to change the unit of measure-

ment, follow these steps:

1.

Press the button (3) to change the unit of measurement. See

(page 8).

Power

Speed

Head

Flow

Parameter

button

Parameter

button

Parameter

button

Parameter

button

2.

When flow and head are displayed, by pressing the button (3) for

more than one second at each of these parameters, the unit of

measurement automatically changes as below:

• Flow: m3/h

↔

gpm (US)

• Head: m

↔

ft

6.2 Start or stop the pump

CAUTION:

• The pump must not run dry as this can result in prema-

ture failure of the bearings in a very short time. Fill and

vent the system correctly before first start-up. The pump

rotor chamber will be vented after the pump is powered

on with an automatic air venting procedure. "deg" will

be displayed indicating degassing process.

NOTICE:

The system cannot be vented through the pump.

• Start the pump in one of the following ways:

• Switch on power to supply the pump.

• Close the start/stop contact by jumpering terminals 11 and

12 or through a remote dry contact..

• Send start command through the communication bus.

The pump starts pumping in constant pressure mode with the fol-

lowing default set points:

7.5 ft

15–XX (Max head 15 ft)

10 ft

20–XX (Max head 20 ft)

18 ft

36–XX (Max head 36 ft)

20 ft

40–XX (Max head 40 ft)

27.5 ft

55–XX (Max head 55 ft)

32.5 ft

65–XX (Max head 65 ft)

For more information about how to change setting, see

(page 10).

• Stop the pump in one of the following ways:

6 System Setup and Operation

10

ecocirc

®

XL Installation, Operation, and Maintenance manual

Summary of Contents for Bell & Gossett Ecocirc XL

Page 1: ...Installation Operation and Maintenance manual ecocirc XL...

Page 2: ......

Page 17: ...Manual de instalaci n operaci n y mantenimiento ecocirc XL...

Page 18: ......

Page 35: ...Guide d installation d utilisation et d entretien ecocirc XL...

Page 36: ......

Page 51: ......