Installation

Pump location guidelines

Guideline

Explanation/comment

Make sure that the space

around the pump is sufficient.

This facilitates ventilation, inspection, maintenance, and service. Xylem

recommends that the service valves on the suction and discharge of all circulators

are installed so they can be serviced or replaced without draining the system.

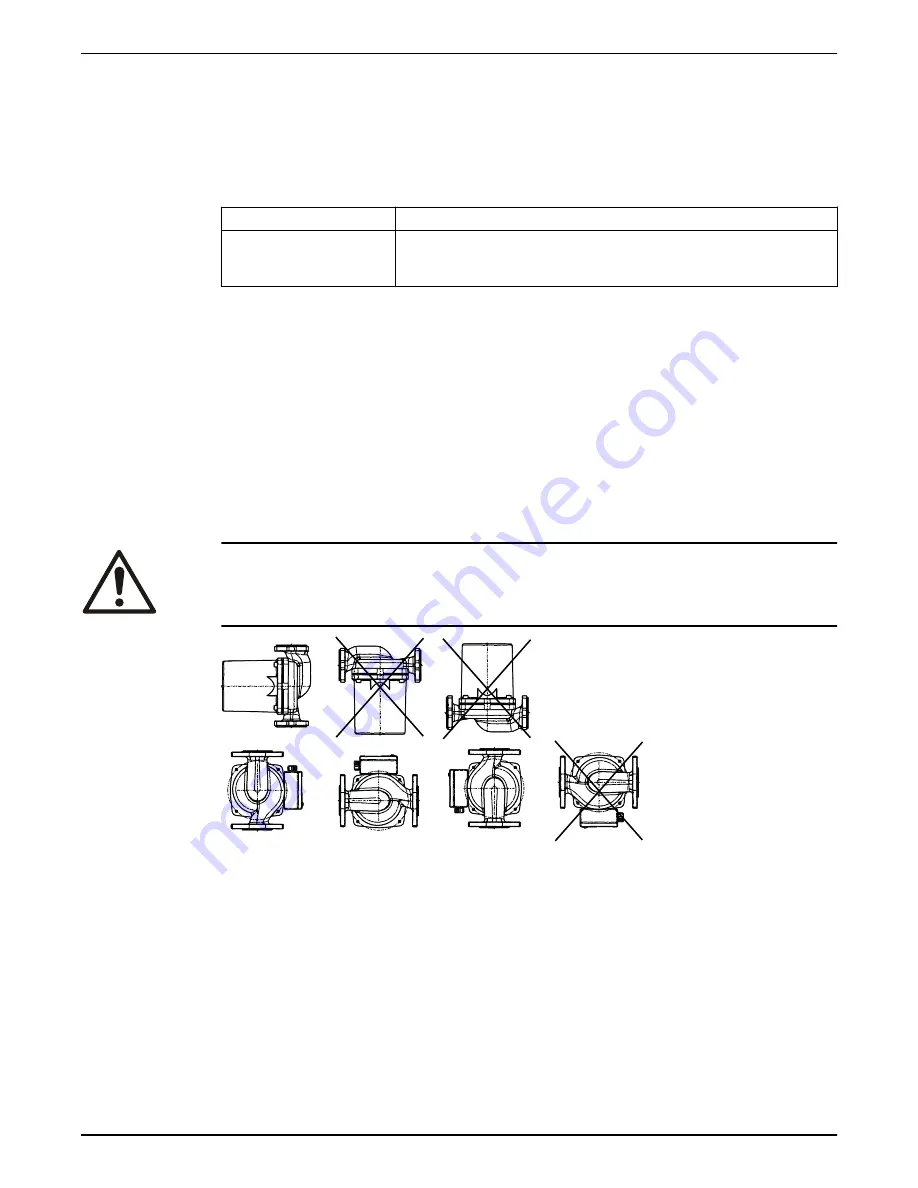

Pump orientation

You can install this pump to discharge up, down, left, or right. However, make sure that

you install the pump according to these pump orientation guidelines:

• Only install the pump with the motor shaft horizontal.

• The arrow on the pump body must point in the direction of the flow.

• You must position the conduit box on the top or to the side of the motor housing. If

you need to change the position of the conduit box, change it before you start the

installation. If the pump is already installed, see

Remove the pump from an existing

(page 15) before proceeding.

Change the conduit position

CAUTION:

Burn or projectile hazard. Make sure the power is turned off before placing anything

inside the discharge opening to move the impeller.

Figure 1: Conduit box position

1. While supporting the motor assembly, use a 3/16 wrench in order to remove the four

1/4-20 Allen screws.

2. Remove the motor assembly from the pump body and rotate it to the desired

position.

3. Replace the Allen screws and tighten them evenly in a diagonal method to 60 in-lbs.

4. Check to see that the impeller turns freely. Insert your finger in the discharge port of

the pump body until you can feel the impeller and rotate it with your fingertip.

The arrow on the pump body points in the direction of the discharge. If the impeller

does not turn easily, repeat the disassembly/ reassembly process.

Installation

8

NRF

™

-25,36,45/NBF

™

-25,36, and 45 Circulator Installation, Operation, and Maintenance Manual