Parameter

Measurement

R

1

U

1

— ground

R

2

V

1

— ground

R

3

W

1

— ground

R

4

U

1

— V

1

R

5

U

1

— W

1

R

6

V

1

— W

1

2. With an ohm meter, check that R

7

— R

9

are reasonably uniform.

Parameter

Measurement

R

7

U

1

— U

2

R

8

V

1

— V

2

R

9

W

1

— W

2

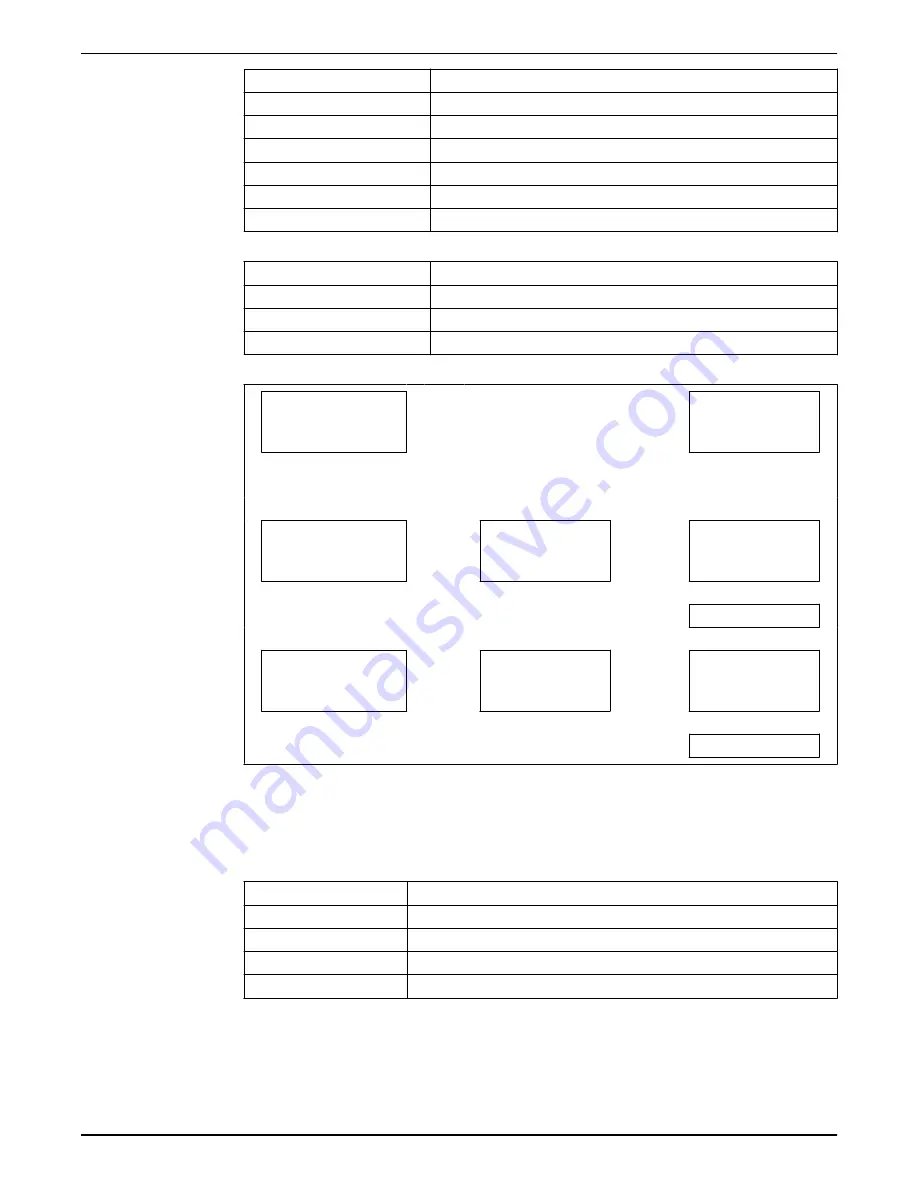

3. Use the following flowchart to determine the action needed.

Insulation test

R

1

–R

6

: 1 or more value is

0 MΩ

→

Yes

→

→

→

New stator, and BRK

↓

No

↓

Insulation test

R

1

–R

6

: All values are > 5

MΩ

→

Yes

→

Are R

7

, R

8

and R

9

reasonably uniform?

→

Yes

→

BRK

(Stator is OK.)

↓

↓

No

→

→

No

→

New stator, and BRK

↓

Insulation test

R

1

–R

6

: 1 or more value is

0.1–5 MΩ

→

Yes

→

Are R

7

, R

8

and R

9

reasonably uniform?

→

Yes

→

Clean and dry stator,

and BRK

↓

→

→

No

→

New stator, and BRK

Basic Repair Kit (BRK): Mechanical seals, bearings and O-rings

4.2.3 Trace faults in the wet end

Check the status of the wet-end components to determine the service needed.

The following table shows the general service items.

Service level

Description

1

Trimming

2

Wear Part Kit (impeller and suction cover)

3

Hydraulic Repair Kit (diffuser and oil house bottom)

4

Wear Part Kit plus Hydraulic Repair Kit

4.3 Torque values

All screws and nuts must be lubricated to achieve correct tightening torque. Screws that

are screwed into stainless steel must have the threads coated with suitable lubricants to

prevent seizing.

4 Maintenance

22

2620.172/.281 Service and Repair Instructions

Summary of Contents for Flygt 2620.172

Page 1: ...Service and Repair Instructions 885611_2 0 2620 172 281...

Page 2: ......