• Pump end only (bare pump)

• Pump less motor

• Pump, motor, & baseplate

Use the following recommended ways of handling HSC pump assemblies.

• The pump assembly should remain horizontal during transport and lifting.

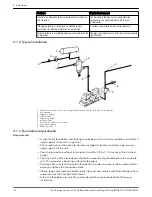

• Lifting the pump end only (bare pump) should be done by placing one end of the

slings around or as close to the casing barrel as possible. After the slings are attached

to the unit, recheck to ensure they are securely in place. Make sure the slings are

adjusted to obtain an even lift.

Figure 1: Lifting pump end only with nylon sling, chain, or wire rope

• Lifting the pump less motor or the pump, motor, & baseplate should be done by

utilizing a forklift under the entire unit. Always take extra precaution to ensure the

weight is balanced & equally distributed across both forks. When the baseplate of the

assembly is structural channel construction, the pump and base plate should be set in

place first. The motor should then be separately lifted & mounted to the unit.

• Pump, base, and driver assemblies where the base length exceeds 100 inches may not

be safe to lift as a complete assembly. Damage to the baseplate may occur. If the

driver has been mounted on the baseplate at the factory, it is safe to lift the entire

assembly. If driver has not been mounted at the factory and the overall baseplate

length exceeds 100 inches, do not lift the entire assembly consisting of pump, base,

and driver. Instead lift the pump and baseplate to its final location without the driver.

Then mount the driver.

2 Transportation and Storage

8

G&L Pumps Series A-C 8100 Base Mounted Centrifugal Pump INSTRUCTION MANUAL