Guideline

Explanation/comment

Take into consideration the occurrence of unwanted noise

and vibration.

The best pump location for noise and vibration

absorption is on a concrete floor with subsoil

underneath.

If the pump location is overhead, undertake special

precautions to reduce possible noise transmission.

Consider a consultation with a noise specialist.

Make sure there is a suitable power source available for the

pump driver.

The electrical supply must match the motor nameplate

specifications.

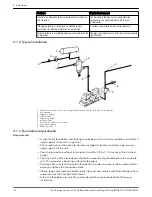

4.1.2 Typical installation

4

5

6

7

8

9

1

2

3

1. Compression tank (locate the compression tank on the suction side of the pump)

2. Air separator

3. Supply to system

4. Circuit setter

5. Triple duty valve

6. Isolation valve

7. From boiler chiller or converter

8. Cold water supply

9. Reducing valve

4.1.3 Foundation requirements

Requirements

• A substantial foundation and footing should be built to suit local conditions and form a

rigid support to maintain alignment.

• The foundation must be able to absorb any type of vibration and form a permanent,

rigid support for the unit.

• Pour the foundation without interruption to within 1/2 to 1–1/2 inches of the finished

height.

• The top surface of the foundation should be scored and grooved before the concrete

sets. This provides a bonding surface for the grout.

• Provide a flat, substantial concrete foundation in order to prevent strain and distortion

when you tighten the foundation bolts.

• Sleeve-type and J-type foundation bolts are most commonly used. Both designs allow

movement for the final bolt adjustment.

• Allow the foundation to cure for several days before you proceed with the pump

installation.

4 Installation

14

G&L Pumps Series A-C 8100 Base Mounted Centrifugal Pump INSTRUCTION MANUAL