4

• If the pump is operated against a low discharge pres-

sure, it may be noisy. Throttle down the discharge gate

valve until the noise is eliminated. This restriction will

not cause any appreciable loss in capacity.

OPERATING

PRIMING

• Fill the pump tank with liquid before starting. This

may be done through the elbow on the side of the tank.

Use pipe compound when replacing the plug in the

side elbow. These Goulds Water Technology prime and

reprime themselves providing the pump tank is filled

with liquid. Should you lose this liquid from the tank

accidentally or by draining purposely, it will be neces-

sary to refill it with liquid before starting. High suction

lifts, or long suction lines, require additional time and

reduce the performance of the pump. Should you have

difficulty, refer to the Troubleshooting Guide.

• Always keep liquid in the pump tank. No further

lubrication of the pump end is necessary including the

seal assembly. If flow does not start within five minutes,

stop the motor and determine cause (see Trouble-shoot-

ing Guide). Be sure all suction and discharge valves are

open when the pump is priming. Operating the pump

with a closed valve in the system can cause pump dam-

age.

ROTATION

• Your pump is specifically designed to rotate as indicated

by the arrow on the pump tank. Three phase motors

can rotate in either direction. Check the rotation. Inter-

changing any two leads of a three phase motor will

reverse the rotation, if this is found necessary.

WINTER STORAGE

• During freezing weather, it is especially important to

drain all of the liquid from the pump tank. This will

prevent ice from cracking the tank or internal parts.

• To maintain the excellent performance of the pump, fol-

low the motor manufacturer’s storage instructions.

LUBRICATION

• The latest engineering advancements have been in-

corporated into our self-lubricating shaft seal. The liquid

being pumped cools and lubricates the seal, therefore

the pump should never be run dry. A seal well vent has

been provided to protect the electric motor from liquid

damage should the seal leak. DO NOT plug this vent. If

leakage becomes excessive, replace the seal assembly.

MAINTENANCE

• If your pump is not used for a few days, drain the liquid

completely. This will prevent aggravating costly rust

formations.

All electrical work MUST be done by

a licensed electrician. Before working

on motors be certain that the electrical power is off at

the main junction box. Disconnect the fuse or circuit

breaker and have the main switch tagged “Do Not Ener-

gize This Switch, Personnel Working on Equipment”.

Some motors are equipped with built-

in thermal over-loads to shut off the

motor in the event the temperature becomes excessive

(as a result of mechanical or electrical problems; such

as low voltage, poor ventilation, overloaded lines, etc.).

These motors will restart automatically as the motor

cools down. For safety sake, do not work on any motor,

without first shutting off the electricity at the source as

outlined above in the “Warning”. Also all three phase

motors are not thermal protected and motor starters are

recommended.

INSTRUCTIONS FOR LICENSED ELECTRICIANS:

TURN POWER OFF

1. Determine the voltage of the power supply line to

motor. Voltage, phase, ampere draw, and cycles are

given on the motor nameplate.

The wire used to supply power to the motor must be

large enough to carry the amperes for the required

length without excessive voltage drop. The follow-

ing table is meant to be a guide only to the minimum

proper wire size selection. Always consult local electri-

cal codes.

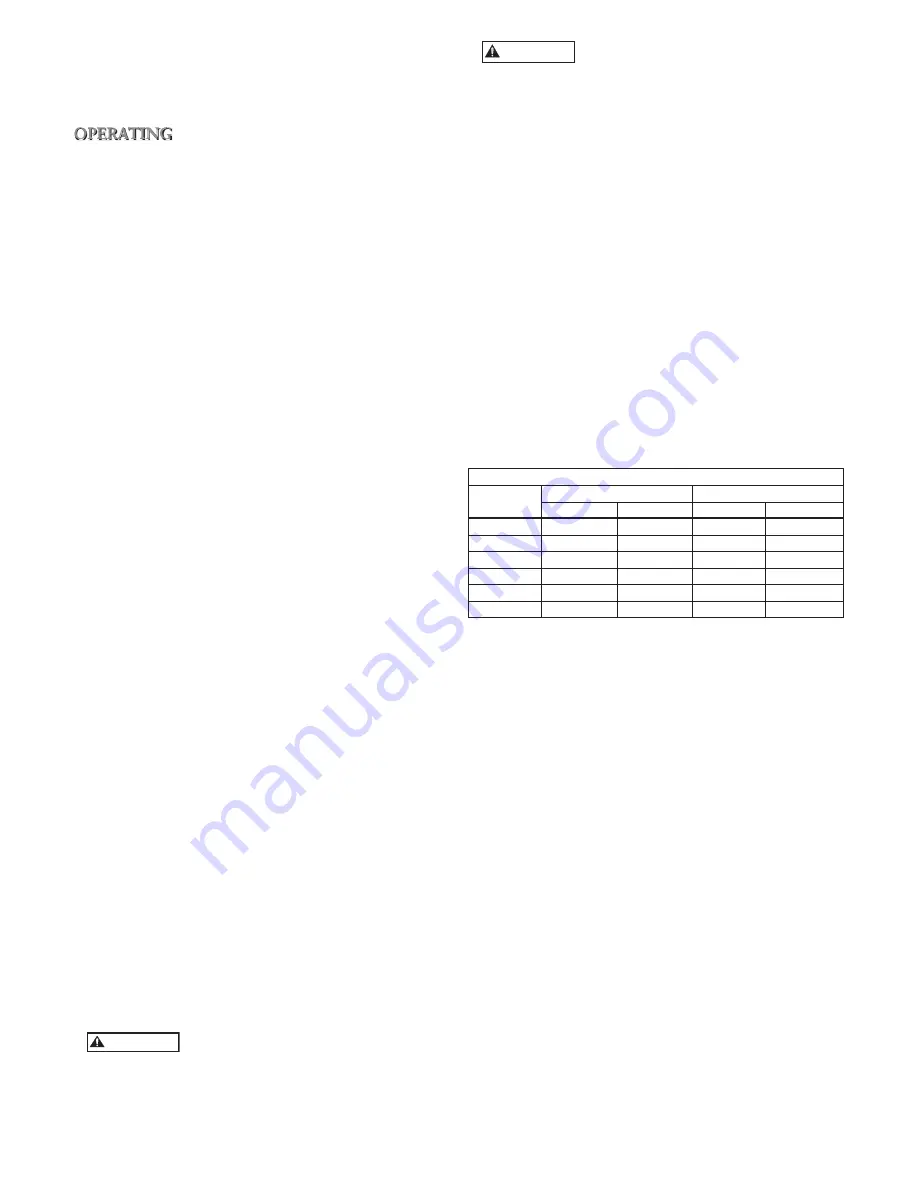

Typical AWG Wire Size for Single Phase Jet Pump Motors

50 Ft. Wire Length

100 Ft. Wire Length

HP

115 V

230 V

115 V

230 V

1

⁄

3

14 – 12 –

½ 14 14 10 14

¾ 12 14 10 14

1 12 14 8 14

1½

10

14

8

12

2 8 12 8 12

WARNING

CAUTION

INSTRUCTIONS FOR LICENSED ELECTRICIANS: