4

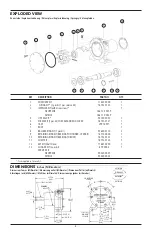

DISASSEMBLY

1.

Remove end cover screws, end cover and O-ring.

2.

Remove impeller by grasping hub with water pump pliers.

3.

Loosen cam screw and remove cam (clean off sealant).

4.

Remove pulley or coupling and key from shaft.

5.

Remove retaining ring which secures bearing/shaft assembly

to pump body.

6.

From impeller end of pump, press bearing and shaft assembly

out of bearing bore. Remove slinger from shaft.

7.

From drive end of pump, press the seal out of the seal bore.

8.

If bearings or shaft need to be replaced, carefully insert two

equal size slot screwdrivers between bearings 180 deg apart.

Simultaneously twist screwdrivers in opposite directions to

separate bearings. Continue to push bearings off of shaft

taking care not to damage bearings or scratch shaft.

9.

Remove snap ring that positions the bearings on the shaft.

NOTE: Inspect all parts for wear or damage and replace where

necessary.

ASSEMBLY

1.

Install bearing positioning snap ring on shaft.

2.

Press bearings (one from each end of shaft) onto shaft and

against positioning snap ring. Slide slinger onto impeller

end of the shaft and position against raised shoulder near

bearings.

3.

Press seal (with lip pointing toward impeller bore) into seal

bore in pump body. Ensure it is seated in bottom of seal bore.

Lubricate seal lip with a small amount of grease.

4.

Align impeller end of shaft with the seal and press shaft/bear-

ing assembly into the bearing bore (push on bearing outer

race). Install bearing retaining ring in retaining ring groove

With concave side facing out toward drive end of shaft.

5.

Apply a thin layer of sealant to screw threads and top of cam

and install in body. Secure with cam screw.

6.

Lubricate impeller bore with light coat of water pump grease

and start impeller into bore with a rotary motion, until impeller

screw engages slot in shaft, then push into bore.

7.

Install O-ring and end cover. Secure with end cover screws.

SERVICE INSTRUCTIONS

Total Head

500 RPM

1160 RPM

1750 RPM

2100 RPM

2450 RPM

3000 RPM

3600 RPM

Head in feet

(Meters)

PSI

(kg/sq cm)

GPM

(L/Min)

HP

GPM

(L/Min)

HP

GPM

(L/Min)

HP

GPM

(L/Min)

HP

GPM

(L/Min)

HP

GPM

(L/Min)

HP

GPM

(L/Min)

HP

10

(3.0)

4.3

(0.3)

1.6

(6.0)

1/12

3.5

(13.3)

1/6

5.8

(22.0)

1/4

6.7

(25.4)

1/3

7.5

(28.4)

1/3

9.4

(35.6)

1/2

11.3

(42.8)

3/4

20

(6.1)

8.7

(0.6)

1.0

(3.8)

1/12

2.6

(9.8)

1/6

5.0

(18.9)

1/4

5.8

(22.0)

1/3

6.6

(25.0)

1/3

8.4

(31.8)

1/2

10.4

(39.4)

3/4

30

(9.1)

13.0

(0.9)

−

−

−

−

3.8

(14.4)

1/4

4.6

(17.4)

1/3

5.3

(20.0)

1/3

7.2

(27.3)

1/2

9.1

(34.4)

3/4

40

(12.2)

17.3

(1.2)

−

−

−

−

−

−

−

−

−

−

5.6

(21.0)

1/2

7.7

(29.2)

3/4

50

(15.2)

21.6

(1.5)

−

−

−

−

−

−

−

−

−

−

−

−

−

−

HEAD CAPACITY TABLES

Model 2620-1101

Capacities reduced by approximately 10% using Nitrile impeller at higher speeds and higher pressures.

NOTE: Progressively longer life may be expected as operating pressures and speeds are reduced. Factory Application Engineering assistance

suggested for operation in light shaded area and recommended for heavy shaded area. Capacitor type motor recommended. Table shows

approximate Head-Flow for new pump in U.S. gallons per minute and liters per minute.

WARRANTY

XYLEM LIMITED WARRANTY WARRANTS THIS PRODUCT TO BE FREE OF DEFECTS AND WORKMANSHIP FOR A PERIOD OF 1 YEAR FROM DATE OF MANUFACTURE. THE

WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, GUARANTEES, CONDITIONS OR TERMS OF WHATEVER NATURE RELATING

TO THE GOODS PROVIDED HEREUNDER, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE,

WHICH ARE HEREBY EXPRESSLY DISCLAIMED AND EXCLUDED. EXCEPT AS OTHERWISE PROVIDED BY LAW, BUYER’S EXCLUSIVE REMEDY AND SELLER’S AGGREGATE LIABILITY

FOR BREACH OF ANY OF THE FOREGOING WARRANTIES ARE LIMITED TO REPAIRING OR REPLACING THE PRODUCT AND SHALL IN ALL CASES BE LIMITED TO THE AMOUNT PAID

BY THE BUYER HEREUNDER. IN NO EVENT IS SELLER LIABLE FOR ANY OTHER FORM OF DAMAGES, WHETHER DIRECT, INDIRECT, LIQUIDATED, INCIDENTAL, CONSEQUENTIAL,

PUNITIVE, EXEMPLARY OR SPECIAL DAMAGES, INCLUDING BUT NOT LIMITED TO LOSS OF PROFIT, LOSS OF ANTICIPATED SAVINGS OR REVENUE, LOSS OF INCOME, LOSS OF

BUSINESS, LOSS OF PRODUCTION, LOSS OF OPPORTUNITY OR LOSS OF REPUTATION. THIS WARRANTY IS ONLY A REPRESENTATION OF THE COMPLETE LIMITED WARRANTY.

FOR A DETAILED EXPLANATION, PLEASE VISIT US AT www.xylem.com/en-us/support/, CALL OUR OFFICE NUMBER LISTED, OR WRITE A LETTER TO YOUR REGIONAL OFFICE.

RETURN PROCEDURE

Warranty returns are conducted through the place of purchase. Please contact the appropriate entity with a receipt of purchase to verify date.