INSTRUCTION MANUAL

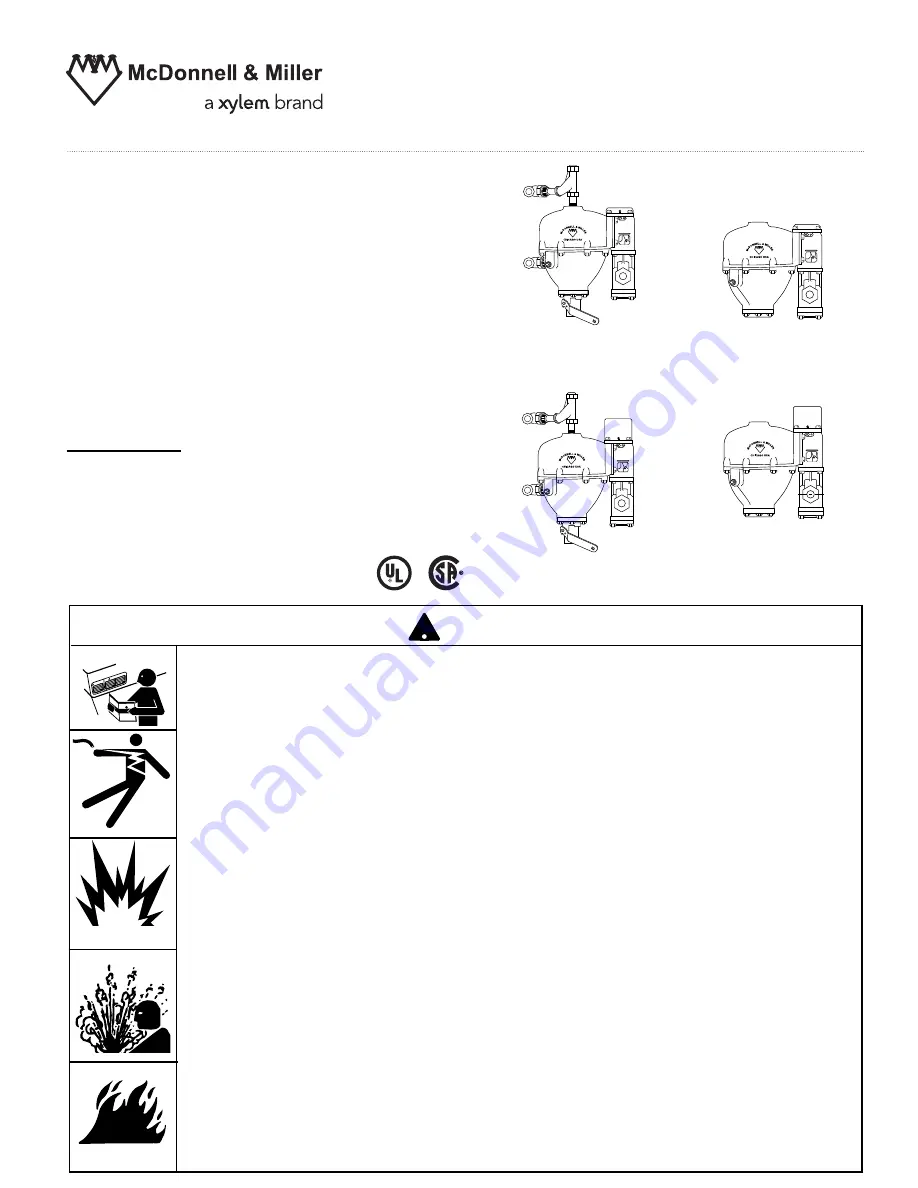

Series 47 and 247

Mechanical Water Feeders

Series 47-2 and 247-2

Combination Mechanical

Water Feeder/Low Water

Cut-Off

For steam and hot water boilers with cold

water feed, to maintain a minimum safe

water level independent of electrical service.

Series 47

Water Feeder

Applications:

• Before using this product read and understand instructions.

• Save these instructions for future reference.

• All work must be performed by qualified personnel trained in the proper application, instal-

lation, and maintenance of plumbing, steam, and electrical equipment and/or systems in

accordance with all applicable codes and ordinances.

• To prevent serious burns, the boiler must be cooled to 80˚F (27˚C) and the pressure must be

0 psi (0 bar) before servicing.

• To prevent electrical shock, turn off the electrical power before making electrical connections.

• The low water cut-off switch must be installed in series with all other limit and operating

controls installed on the boiler. After installation, check for proper operation of all of the

limit and operating controls, before leaving the site.

• We recommend that secondary (redundant) Low Water Cut-Off controls be installed on all

steam boilers with heat input greater than 400,000 BTU/hour or operating above 15 psi

steam pressure. At least two controls should be connected in series with the burner

control circuit to provide safety redundancy protection should the boiler experience a

low-water condition. Moreover, at each annual outage, the low water cutoffs should be

dismantled, inspected, cleaned, and checked for proper calibration and performance.

• Boiler manufacturer schematics should always be followed. In the event that the boiler

manufacturer's schematic does not exist, or is not available from the boiler manufacturer,

refer to the schematics provided in this document.

• To prevent a fire, do not use this low water cut-off to switch currents over 10.2A, 1/2 HP at

120 VAC or 5.1A, 1/2 HP at 240 VAC, unless a starter or relay is used in conjunction with it.

WARNING

CAUTION

!

WARNING

Series 47-2 Combination

Water Feeder Low Water

Cut-Off

Series 247

Water Feeder

Series 247-2 Combination

Water Feeder Low Water

Cut-Off

MM-316E

California Proposition 65 warning! This product contains chemicals known to the

•

state of California to cause cancer and birth defects or other reproductive harm.

Previous controls should never be installed on a new system. Always install new

•

controls on a new boiler or system.

!