Heat / Cooling Meters Calculator Unit

PolluTherm can be combined with PolluFlow

Installation and Operating Instructions

MH 6114 INT PolluTherm, Page 5

new seals. With flanges, make sure that the

cross-section of the pipe is not reduced by the

positioning of the seals.

Installation in cooling systems:

It is recommended to install the flow sensor into

the warm pipe (return) of the cooling system.

PolluTherm X (installation into the warm pipe)

must be used in cooling systems. If Sensus flow

sensors are used, note to the approved

temperature range.

5.2 Installation of the Temperature Sensor

PolluTherm is operated using a pair of

temperature sensors, Type Pt 500. The type of

temperature sensors that can be used is given on

the front of the calculator unit.

In accordance with the guideline of the PTB

TR K 9, heat and cooling meters with nominal

flows of

≤

Qp 6m³/h, only direct immersion is

permitted (refer to MID starter kit) (refer to

Figure 6) when installing the temperature

sensor into new installations of the pipeline

section in the area of the measurement

position with nominal pressures of

≤

16 bar,.

Here, our MID starter kit should be used. This

consists of special ball valves with temperature

sensor seat M10 x 1, with integrated union nuts

and an adapter (refer to Datasheet MH 1131 DE).

These starter kits are compatible with the

temperature sensor types L = 45 mm /

ø

= 5.2

mm and DS 27.5. They are supplied up to

R1“(DN 25).

The EN 1434-2 can be used as a general

installation guideline.

When using Sensus temperature sensors with the

installation lengths of 100 mm and 150 mm, the

active measuring part is measured approx. 10 to

15 mm from the tip of the temperature sensor and

must be located as close as possible to the centre

in the pipeline. For these types, it is

recommended to install as follows:

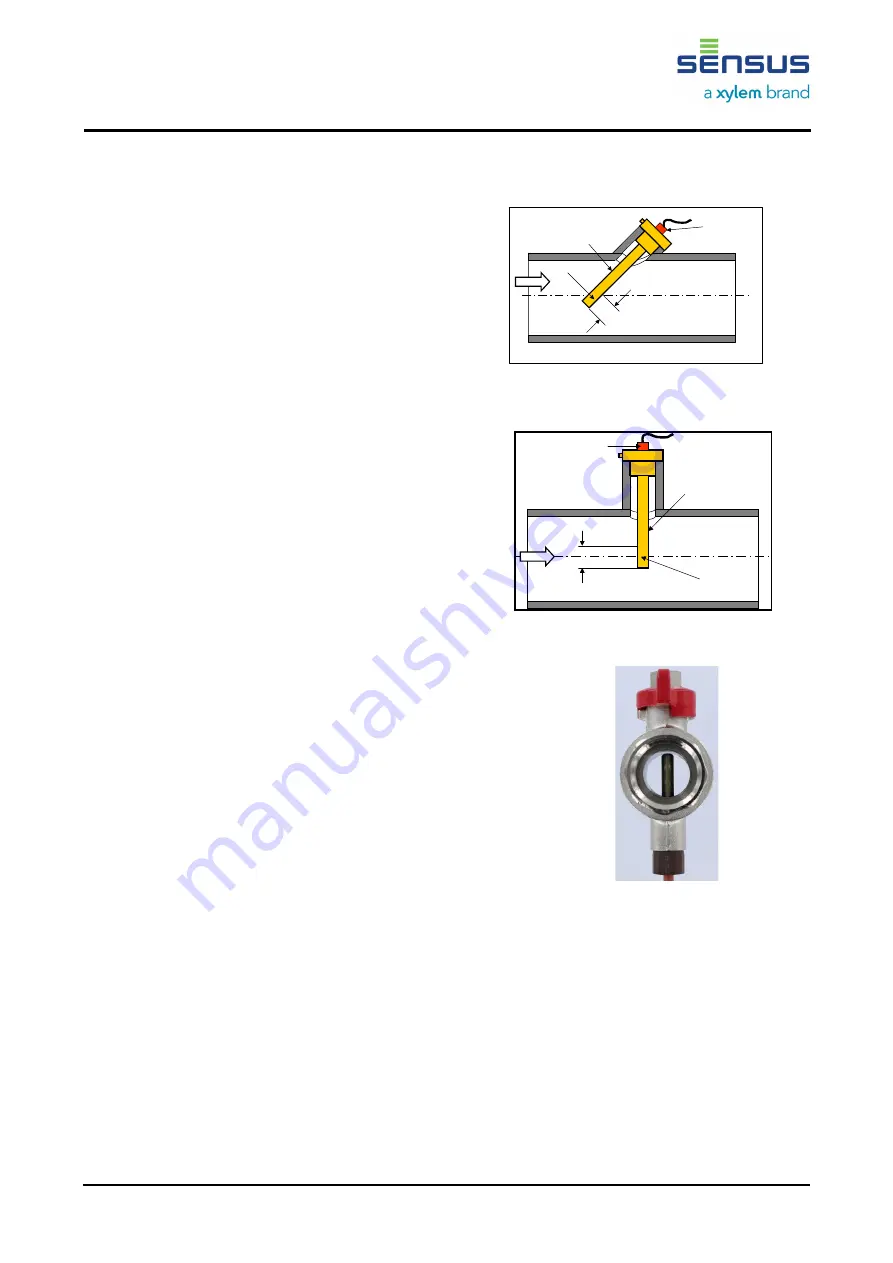

Nominal diameters

≥

DN 80*: Installation of the

temperature sensor at an angle of 45° against the

direction of flow (refer to Figure 4).

Nominal diameters

≥

DN 65*: Installation of the

temperature sensor vertical to the direction of flow

(refer to Figure 5).

* For DN 65 and DN 80, both installation positions are

permitted, up to DN 50, installation is also possible in the pipe

elbow

For larger nominal diameters (from approx. DN

150) the sleeve must be immersed a minimum of

50 mm into the pipeline.

Figure 4: Exemplary illustration for

Nominal diameter DN 50

Figure 5: Exemplary illustration for

Nominal diameter DN 100

Figure 6: temperature sensor, direct

immersion

5.3 Installation of the Calculator Unit

Use the C-rail with two bolts to attach the

calculator in the horizontal position at the required

position. Place the housing on the C-rail and use

a flat-head screwdriver to raise the red snap-in

hook.

Next, press the housing onto the C-rail and

release the snap-in hook. Alternatively, the

calculator unit can also be directly installed onto

the flow sensor.

Messaktiver Teil

Tauchhülse

Tempera

-

turfühler

ca. 10

-

15 mm

Messaktiver Teil

Tauchhülse

Temperaturfühler

ca. 10-15 mm