Revision 3.1

WebRelay

TM

Users Manual

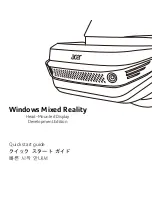

Another way this configuration is useful is to extend the output of a PLC (Programmable Logic Controller)

in a factory to control a motor in another building. The output of the PLC is connected to the input of one

WebRelay

TM

, and the motor is connected to the relay contacts of a second WebRelay

TM

. This allows any

PLC to control devices across an IP network.

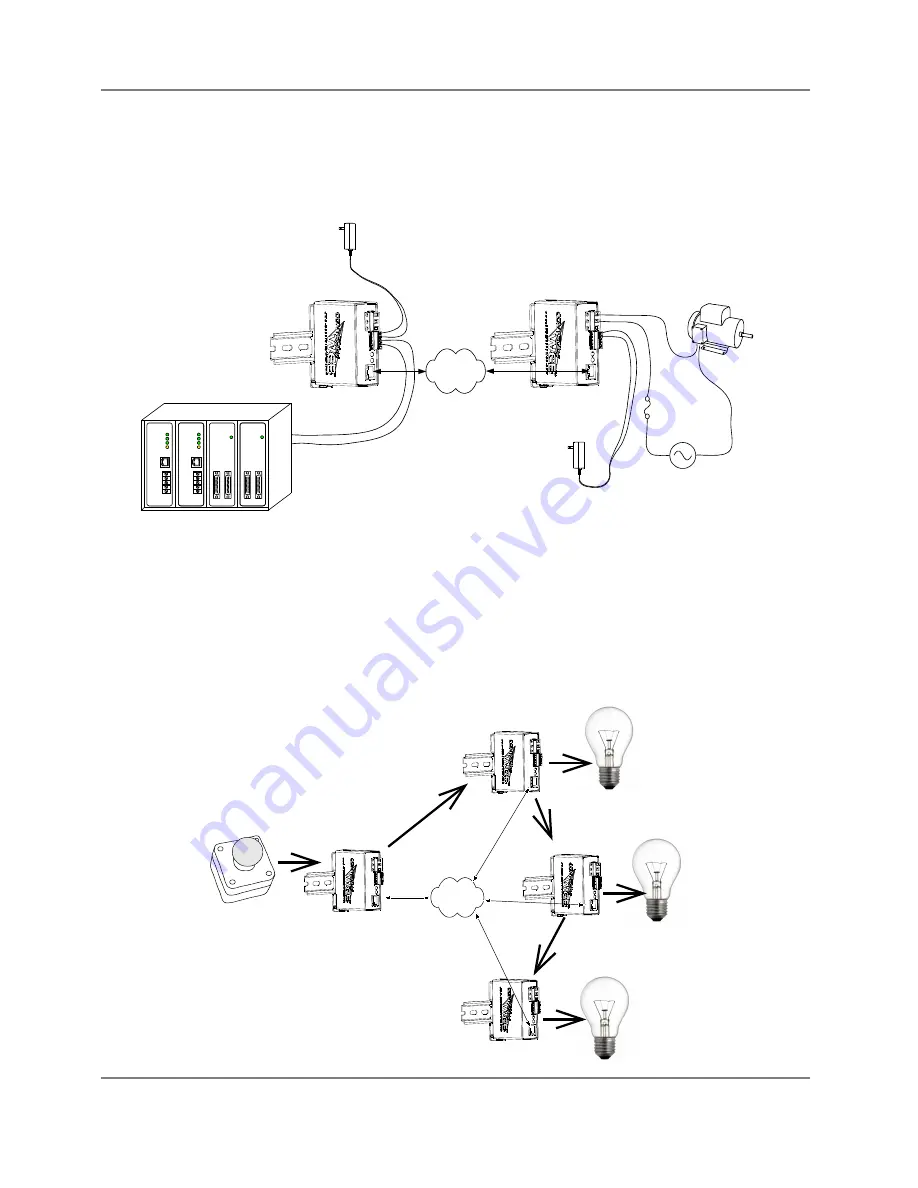

1.4.4 Multiple WebRelay

TM

Operation (No Computer Required for Operation)

For some applications, it is useful to for one WebRelay

TM

to control multiple WebRelays at remote

locations. There is not a way to configure a single WebRelay

TM

to control multiple WebRelays directly, but

it is possible to set up multiple WebRelays in a daisy-chain mode so that one WebRelay

TM

controls a second

WebRelay

TM

which, in turn controls a third WebRelay

TM

and so on. In the illustration below, each

WebRelay

TM

is numbered (1, 2, 3, and 4). A mechanical switch controls WebRelay

TM

1, and

WebRelay

TM

1 controls WebRelay

TM

2, which controls WebRelay

TM

3, which controls WebRelay

TM

4. This

daisy-chain mode is set up by configuring the Relay options in WebRelays 1, 2 and 3 to “

remote command

Xytronix Research & Design, Inc.

page 9

WebRelay

11

1

Power Supply

(Powers WebRelay)

(5VDC or 9-28VDC)

+

5V

D

C

Vin

+

Vin-

In+

IP

Network

Device to be

Controlled

WebRelay

COM

NO

11

1

Power Supply

(Powers WebRelay)

(5VDC or 9-28VDC)

+

5V

D

C

Power Source

(For device to be controlled)

Fuse or

Circuit Breaker

Vin+

Vin-

Programmable Logic Controller

(PLC)

Digital Output

Gnd

RS

-232

AN1

AN2

AN3

AN4

AN5

Power

AF1

AF3

Warn

R

S-232

AN1

AN2

AN3

AN4

AN5

Di

gital I

N

Di

gital OUT

Power

Di

gital IN

Di

gital OU

T

Power

Power

AF1

AF3

Warn

In-

WebRelay 1

11

IP

Network

Control Switch

Device To Be Controlled

Device To Be Controlled

Device To Be Controlled

WebRelay 2

WebRelay 3

WebRelay 4