LCM Menus

UTILITIES

INSTALL RESIN

V1.5

-5-

“Utilities” menu provides the control of the printer. You can instruct to fill the resin tank manually, and calibrate the

printer when necessary.

You can activate resin-filling function manually. Before doing so, make sure the resin bottle, resin tank and the lid are

installed correctly. (See “Unpack & Setup” for details).

“Horizon Calibration” ensures the platform is parallel with the resin tank for more stable printing performance.

Always perform “Horizon Calibration” after changing to a new tank or a tank different the one used for last print.

Select “Yes” and press [OK] to begin:

• “Auto Fill” function is enabled by default. You may skip loading resin manually when auto-fill is enabled.

• Shaking the resin bottle well before use ensures an even color.

• The printer detects the tank level after "Install Resin" is activated. Resin will be filled only when the tank

level is low.

HORIZON CALIB

INSTALL RESIN

BOTTLE BY NOW

NO

►

YES

MAKE SURE PIPES

ARE INSTALLED

CORRECTLY

[

OK

]

FOR NEXT

RESIN TANK IS

FILLING UP NOW

PLEASE WAIT

…

[

OK

]

TO CANCEL

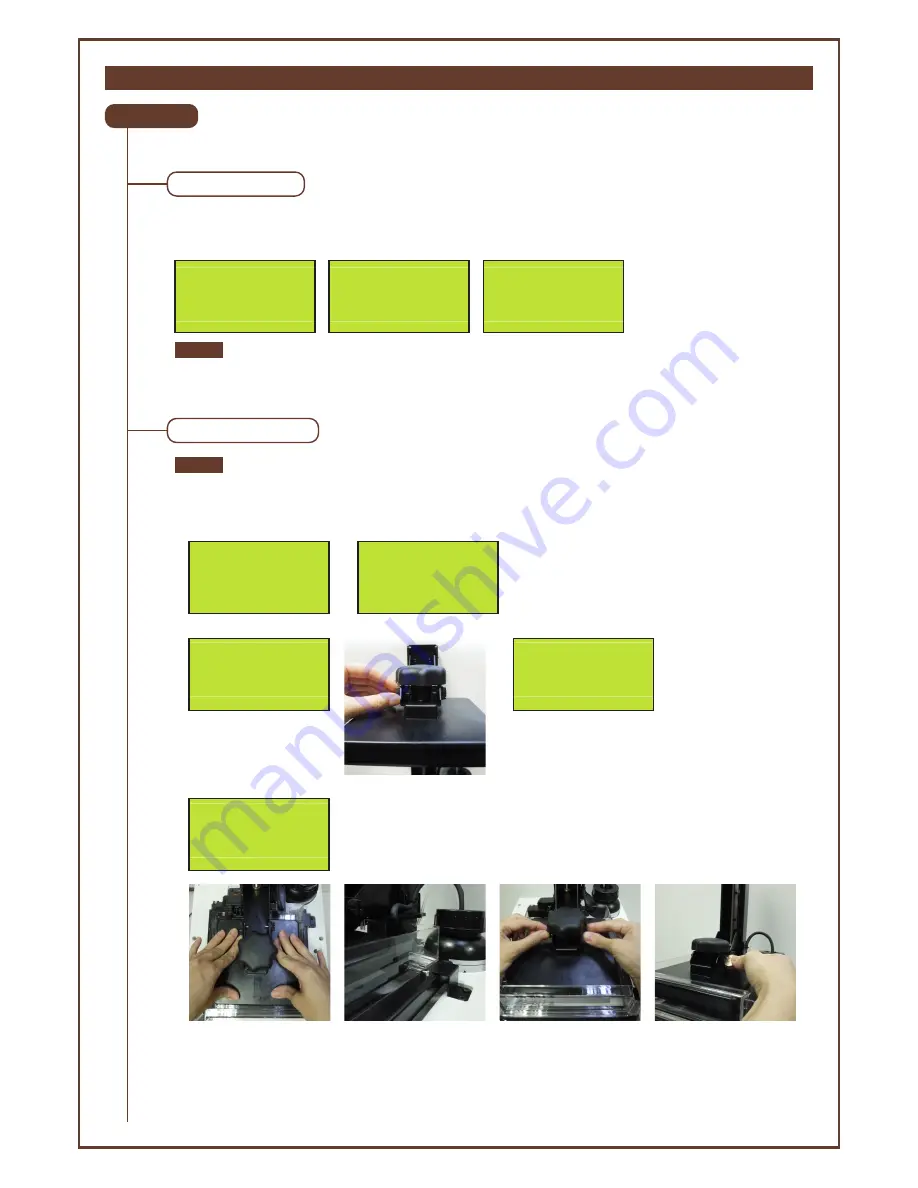

Select “Yes” and press [OK] to begin:

Note

To ensure the accurracy of calibration, please empty the resin tank before calibrating.

Note

①

START HORIZON

CALIBRATION NOW

?

NO

►

YES

②

REMOVE OBJECT

FROM PLATFORM

[

OK

]

TO CONTINUE

③

LOOSEN 4 SMALL

SCREWS ABOVE

THE PLATFORM

[

OK

]

TO CONTINUE

Tighten the screws with

fingers. First tighten the

front screws. Fasten screw

F1 then F2. And tighten

the screws at the back.

Fasten screw B1 then B2.

Finally tighten the screws

with a coin or other tools

(sequence from F1, B1, F2

to B2) and press [OK] to

complete calibration.

When you see the

message above, press the

platform with both hands

3 times. Make sure you

see the right side of the

tank sinks into the tank

slot slightly.

Wait for 5 seconds so the

silicon finish on the tank

can reshape. Check the

tank frame has reposi-

tioned (there's no gap

between the frame

holders).

⑤

TIGHTEN ALL 4

SCREWS ABOVE

THE PLATFORM

[

OK

]

TO FINISH

④

Wait until the platform

descends to the bottom.

PROCESSING

PLEASE WAIT

...

F1

F1

F2

F2

B1

B1

B2

B2