11

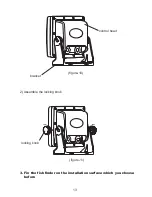

2. Find a better mounting location

a) Fill the hull with enough water to submerge the transducer.

b) In the sump of the boat, place the transducer at the identified mounting position,

face down. To make the transducer in position, some heavy object could be used.

c) Turn on the sonar unit, run the boat to water area that the depth is

about 20feet to test whether the sonar display is normal (if needed, please adjust

the sensitivity and depth range). If not, check the connection between the control

head and the transducer.

d) Run the boat at various speed to see the sonar display, if such phenomena

appears: sonar strength obviously decreasing, signal losing, bottom missing, then

note the speed and choose another location for the transducer, and repeat the step till you

get the best mounting location.

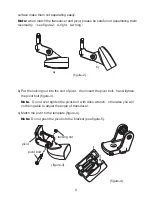

3. The Permanent Shoot-Thru-Hull installation

a) make sure the surface of the chosen location is clear

ǃ

dry and free of any oil,

then sand the mounting surface of transducer with 100 grit sandpaper until it looks

very clean and flat.

b) Wipe off the sand debris on mounting surface with a piece of cloth, and then clean

the mounting surface of hull and transducer with rubbing alcohol.

c) Get a quantity of epoxy and hardener, mix them in a certain proportion and thor-

oughly, slowly stir them on a paper plate. Avoid forming air bubbles in the epoxy.

d) When the epoxy looks unworkable (about 20minietes are needed from the begin-

ning you mixing them), make sure there are no air bubbles in the epoxy layer, then

spread a thin layer of epoxy on the surface of transducer, a comparably thick layer

to the surface of sand area on the hull.

e) Press the transducer into the epoxy of the sanding area on the hull with a slight

twisting motion, forcing any air bubbles out from underneath. Make sure the face

of the transducer will be parallel with the hull after you finish all the above job.

Warning:

do not bump the transducer while the epoxy is wet. It will take about

24 hous for the epoxy curing completely.

Note:

weight the transducer with some heavy object to prevent it from moving

during the epoxy curing, when the epoxy cures completely, drain out the water

from the hull.

f) Route the cable to the control head, and now it’s ready to use.