10

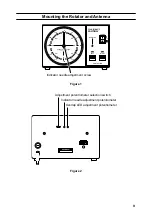

Mounting the Rotator and Antenna

Installation of Rotator and Antenna on Tower

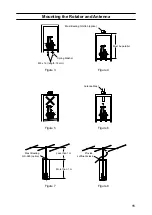

The procedure for installing the rotator depends on the type of tower used. The following in-

structions are generally applicable to most guyed, crank-up, or roof towers.

1. Attach the rotator to the tower’s rotator mounting plate, using the supplied M8 x 16 bolts

and spring washers. It is recommended that the tips of the bolts be lightly dipped in lubri-

cating grease, to ease disassembly in the future.

2. If a thrust bearing (such as the optional Yaesu model GS-065) is to be utilized, mount it on

the top of the tower (see Figure 4) using the supplied hardware.

3. Using a “gin pole” or other raising fixture, insert the antenna mast through the bearing from

above, and set the mast in the rotator’s mast clamps. Do not tighten the mast clamps at

this time;just secure the U-bolts to the point where the mast is held in place, but is allowed

to rotate freely.

4. Partly tighten the thrust bearing’s mast bolts, so as to center the mast in the thrust bear-

ing. When you are satisfied that the mast is centered, back off slightly on each of the thrust

bearing’s mast bolts, and (if possible) lift the mast by a very

small amount

(approximately 5

mm or 3/16”), just enough to lift the bottom of the mast slightly off the top of the rotator. Now

re-tighten the thrust bearing’s mast bolts to secure the mast in place. This procedure takes

all the weight of the mast and antennas off of the rotator; all weight is being carried by the

thrust bearing. If no thrust bearing is used, the mast should be allowed to rest on the top of

the rotator.

5. Verify that the mast rotates freely in the mast clamps, and that the mast is properly centered

in the clamps. Now tighten the nuts on the U-bolts of the mast clamp.

Caution:

Do not over-tighten the nuts on the mast clamps. They should be tightened until

the spring washer becomes flat, then tightened further by 1/2 to one turn maxi

-

mum.

6. Install the rotator control cable’s round plug into the jack on the side of the rotator’s base,

and tighten the connector ring to secure the connector. Slide the rubber boot over the con-

nector; while putting a slight amount of inward pressure on the rubber boot, use electrical

tape to secure the back end of the rubber boot to the cable. This slight inward pressure on

the rubber boot will enhance the weatherproofing of the installation. Secure the control ca

-

ble to the tower in several places, using electrical tape and/or UV-resistant cable ties.

7. Install the antenna(s) on the mast. Use a compass to align the forward end of the beam

toward North (0º)

or whichever direction to which you set the “Left Stop” in Step 12 of

the previous section.

8. Provide sufficient slack in the coaxial cable such that the antenna can rotate over its full

450º range without putting any tension on the coax (see Figure 8). Secure the coax to the

tower, using electrical tape and/or UV-resistant cable ties.

9. Installation is now complete. If you have scratched through the melamine coating of the

rotator during installation, you may wish to apply several coats of clear acrylic spray to help

protect the bare metal from corrosion.

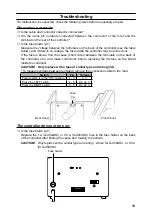

After installation is complete, test the system by operating the rotator through the entire

range of its rotation. It is helpful to do so with the help of an observer, so that rotation can be

stopped if some obstruction, binding, or tension on the coaxial cable’s turning loop should

be encountered during the performance test.

Installation Note

If using a roof tower with a long mast between the top of the tower and the antenna, the use of

a “Guy Bearing” is highly recommended. The Yaesu GS-050 and GS-065 include guying “ears”,

which allow attachment of guy cables. As installing a guying system may cause the center-lines

of the guy bearing and the rotator to become mis-aligned, be certain to check the roof tower at-

tachment and guy cable alignment to ensure that the mast is straight.