Chapter 4: Operation and Adjustment ES2 Series Servo User Manual Lite V1.0

23

4.2 Operating mode instructions

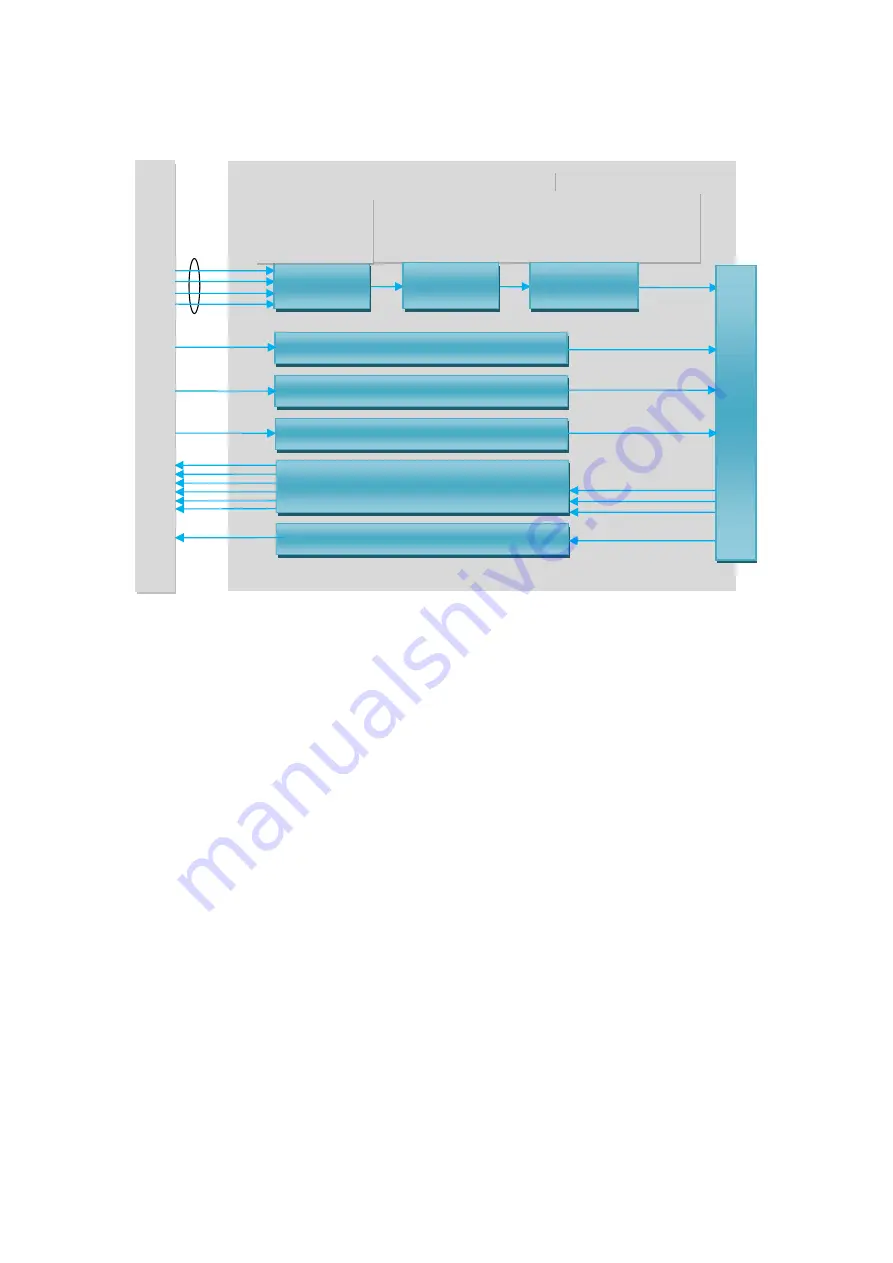

4.2.1 Position mode

Position mode is a common working mode of the servo drive. The main steps are as follows:

1. Connect the power supply of the servo main circuit and control circuit correctly, as well as the motor

power line and encoder line. After the power is turned on, the servo panel displays “rdy”, indicating

that the servo power supply is correctly wired and the motor encoder is wired correctly.

2. Perform a servo JOG test run by pressing the button to confirm that the motor can run normally.

3. Refer to the wiring instructions to connect the pulse/direction input and pulse command input in the

CN1 terminal and the necessary DI/DO signals, such as servo enable, positioning completion, etc.

4. Make settings related to the position mode. Set the DI/DO according to actual application. The

function code refers to P02 group. In addition, if necessary, you need to set the functions such as

return-to-origin and frequency division output. For details, see the product manual.

5. Enable the servo and control the servo motor rotation by sending a position command from the host

computer. First, let the motor rotate at a low speed, to confirm whether the rotation direction and the

electronic gear ratio are normal, and then adjust gain setting. Please refer to the debugging procedure in

Section 4.4.

COIN output

Pulse divider output

PERR_CLR

input

INHIBIT

input

POS_DIR input

P04-23Positioning

completion output

P04-24

Positioning width

P04-07 gear ratio numerator 1

P04-09 gear ratio denominator 1

P04-11 gear ratio numerator 2

P04-13 gear ratio denominator 2

P04-05

Number of command pulses

required for one motor round

P04-03Position command

smoothing filter

P04-04

Position command

FIR filter

Pulse input

Command direction selection function

Pulse input inhibit function

Position deviation clear function

Command

input

Electronic

gear ratio

Position command

filtering

Positioning completed

P

os

iti

on

a

dju

stm

en

t c

on

tro

lle

r

Frequency division output function

P04-00

command

source

P04-21

command

form

H

os

t c

om

pu

te

r c

on

tro

lle

r