Chapter 4: Operation and Adjustment ES2 Series Servo User Manual Lite V1.0

26

Set the electronic gear ratio according to the actual situation of the machine and the host computer.

Function

code

Name

Setting range

Min

unit

Factor

y

setting

Effective time

Type

Related

mode

P04

07

gear ratio numerator 1

1~1073741824

1

4

Immediately

Set

when

motor is

running

P

P04

09

gear ratio denominator

1

1~1073741824

1

1

Immediately

P

P04

11

gear ratio numerator 2

1~1073741824

1

4

Immediately

P

P04

13

gear ratio denominator

1

1~1073741824

1

1

Immediately

P

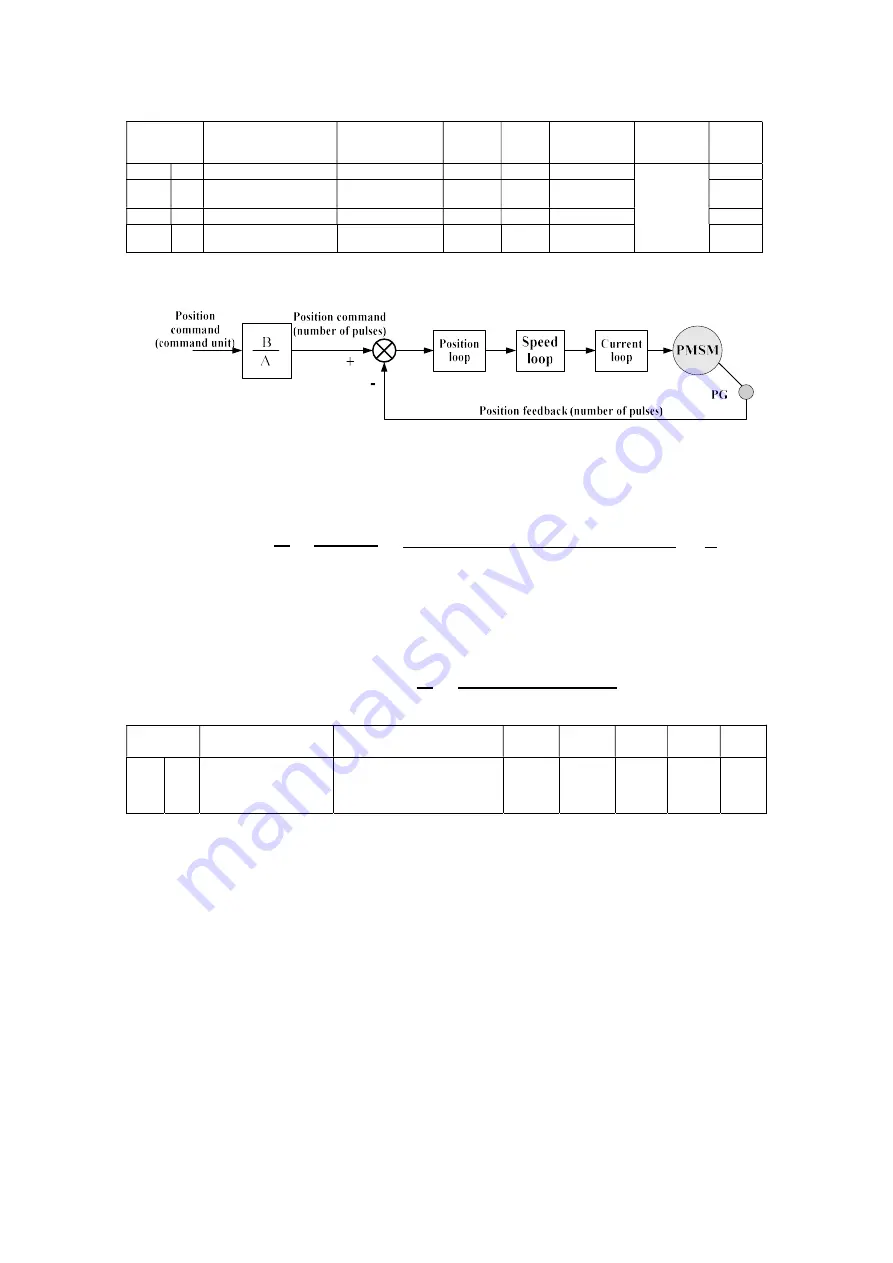

The schematic diagram of the electronic gear ratio is as follows:

a

)

When P04-05=0, the motor and the load are connected through the reduction gear.

Assuming that the reduction ratio of the motor shaft to the load machine side is n/m (motor rotate

m round, load shaft rotate n round), the calculation of the electronic gear ratio is as follows :

electronic gear ratio

=

=

(

)

×

This model drive supports up to 2 sets of electronic gear ratios, and the gear ratio selection can be

completed by using the electronic gear ratio switching function FunIN.23.

b) When P04-05≠0:

electronic gear ratio

=

Function

code

Name

Setting range

Min

unit

Factory

setting

Effecti

ve time

Type

Related

mode

P04 05

Number of pulses

required for one

motor round

0P/Rev~1048576P/Rev

1P/Rev 0P/Rev

Re-

power

Setting

after

motor

stop

P

At this time, the two sets of electronic gear ratio and electronic gear switching function are invalid.