7

Inspection and maintenance

07.2020

123

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

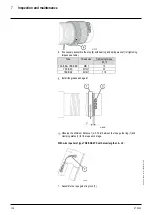

Adjusting operational hoist limit switching, “bottom” (B

)

Actuate the DOWN-button in the control pendant with caution.

Lower the load hook to 0.39 in in front of the switching point (observe the minimum

distance “d”).

–

If the operational hoist limit switch should switch off beforehand, turn the

adjustment screw “S6”

anticlockwise 1 revolution and repeat step 2.

Turn the adjustment screw “S6”

clockwise until the switch contact latches audibly.

Actuate the UP-button in the control pendant.

–

The “bottom” operational hoist limit switching position has been set.

Dim.

[in]

a

*1

50 Hz

60 Hz

Reeving

1PS

1PD

5.1

5.9

1

2PS

2PD

2.8

3.1

2

4PS

4PD

1.6

2

4

b

YK

/SK

with

frequen

cy

in

ve

rter

b = V × t × 0.023

ft

V = Hoist speed [fpm]

t = Brake ramp [s]

(Factory setting = 1.5 s

)

Example:

YKC/SKC-L05-

…S2

64

-V

b = 64 × 1.5 × 0.023 = 2.2

ft

c

*1

2.4

d

4.7

e

Effective hook path

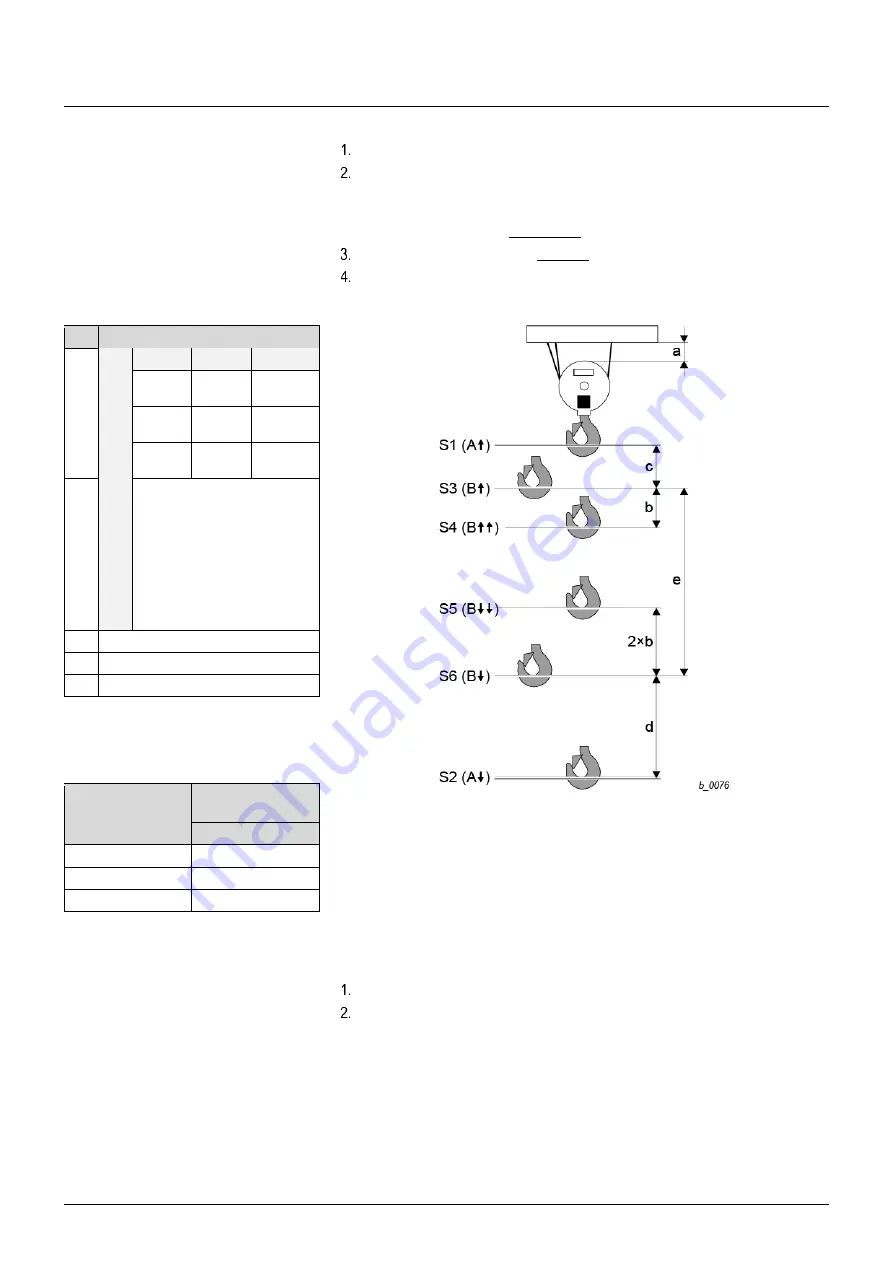

*1

With the option

hook operated hoist limit

switch

(see section 4.11),

dimension “a” increases by 3.9

in,

dimension “c” increases in accordance with

the table.

Type

Dimension “c”

enlargement

[in]

YKA/SKA, YKB/SKB

2

YKC/SKC, YKE/SKE

3.9

YKD/SKD

5.9

Adjusting emergency hoist limit switching,

“bottom” (A

)

The “bottom” operational hoist limit switching position must be set.

Actuate the DOWN button in the control pendant with caution.

Observe the hoisting movement, until operational hoist limit switching (B

) switches

off in the bottom hook position.