11

Technical data

156

07.2020

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

11.2

Hoist

The designation of the type of wire rope hoist and the motor installed can be seen from

the rating plate/factory certificate.

All technical data given refer to the standard version and standard operating conditions.

The technical data given in the order acknowledgement or individual documentation apply

for optional versions and off-standard applications. Motor specifications for more

information and further technical details are available on request.

11.2.1

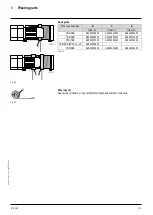

Pole-changing hoist motors 12/2H..-MF 50Hz

50 Hz

Motor

*3

Power

Duration

factor

Switching/

hour

Nominal

current

Starting

current

Nominal

current

Starting

current

cos phi k

Main fuse CC / J

*2

220…240

V

380…415

V

220…240

V

380…415

V

[HP]

CDF [%]

[c/h]

I

N

[A]

I

K

[A]

I

N

[A]

I

K

[A]

[A]

12/2H33-MF

0.5/3.2

20/60

480/240

6.4/10.4

13.2/67.8

3.7/6.0

7.6/39.0

0.78/0.83

20

15

0.5/3.9

20/50

360/180

6.6/12.2

3.8/7.0

0.7/4.8

20/40

240/120

7.1/14.0

4.1/8.2

12/2H42-MF

0.5/3.9

20/60

480/240

8.7/12.2

15.0/76.5

5.0/7.0

8.6/44.0

0.77/0.84

20

15

0.7/4.8

20/50

360/180

8.7/14.6

5.0/8.4

0.9/6

20/40

240/120

9.6/17.0

5.5/9.9

12/2H62-MF

1.3/8

20/60

480/240

15.5/23.5

27.8/144.0

8.9/13.5

16.0/83.0

0.69/0.77

50

25

1.6/10.1

20/50

360/180

16.0/28.0

9.0/16.0

12/2H71-MF

*1

1.3/8

20/60

480/240

15.5/23.5

27.8/144.0

8.9/13.5

16.0/83.0

0.69/0.77

50

30

1.6/10.1

20/50

360/180

15.7/28.3

9.0/16.3

1.9/12.1

20/40

240/120

19.0/33.0

11.0/19.0

12/2H72-MF

*1

2.7/16.1

20/50

360/180

20.9/43.5

43.5/252.0

12.0/25.0

25.0/145.0

0.68/0.67

80

50

3.4/20.1

20/40

240/120

24.0/56.0

14.0/32.0

12/2H91-MF

*1

6.7/40.2

20/40

240/120

45.0/101.0

78.3/435.0

26.0/58.0

45.0/250.0

0.60/0.70

100

60

50 Hz

Motor

*3

Power

Duration

factor

Switching/

hour

Nominal

current

Starting

current

Nominal

current

Starting

current

cos phi k

Main fuse CC / J

*2

420…460

V

500…525

V

420…460

V

500…525

V

[HP]

CDF [%]

[c/h]

I

N

[A]

I

K

[A]

I

N

[A]

I

K

[A]

[A]

12/2H33-MF

0.5/3.2

20/60

480/240

3.4/5.5

6.9/35.5

3.0/4.8

6.1/31.2

0.78/0.83

15

15

0.5/3.9

20/50

360/180

3.5/6.4

3.0/5.6

0.7/4.8

20/40

240/120

3.7/7.5

3.3/6.6

12/2H42-MF

0.5/3.9

20/60

480/240

4.5/6.4

7.8/40.0

4.0/5.6

6.9/35.2

0.77/0.84

15

15

0.7/4.8

20/50

360/180

4.5/7.6

4.0/6.7

0.9/6

20/40

240/120

5.0/9.0

4.4/7.9

12/2H62-MF

1.3/8

20/60

480/240

8.1/12.3

14.5/75.5

7.1/10.8

12.8/66.4

0.69/0.77

25

20

1.6/10.1

20/50

360/180

8.2/14.5

7.2/13.0

12/2H71-MF

*1

1.3/8

20/60

480/240

8.1/12.3

14.5/75.5

7.1/10.8

12.8/66.4

0.69/0.77

25

25

1.6/10.1

20/50

360/180

8.2/14.8

7.2/13.0

1.9/12.1

20/40

240/120

10.0/17.3

8.8/15.0

12/2H72-MF

*1

2.7/16.1

20/50

360/180

10.9/22.7

22.7/132.0

9.6/20.0

20.0/116.0

0.68/0.67

50

30

3.4/20.1

20/40

240/120

12.7/29.0

11.0/26.0

12/2H91-MF

*1

6.7/40.2

20/40

240/120

24.0/53.0

40.9/227.0

21.0/47.0

36.0/200.0

0.60/0.70

60

50

Tab. 42

Motor currents at other voltages:

Formula

𝐼

𝑥 𝑉

= 𝐼

400 𝑉

∗

400 𝑉

𝑥 𝑉

*1 Operation only with special starting circuit via 12-pole winding.

*2 The 2-pole starting current for main hoist and the rated current for the travel motor were taken into

consideration when selecting the main fuse.

*3 The motors are designed for rated voltage ranges. In accordance with EN 60034 a voltage tolerance of

±5 % and a frequency tolerance of ±2 % apply on top of the rated voltage ranges. The maximum current

occurring in the rated voltage range is given.