4

Installation

07.2020

35

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

4.5

Double rail trolley (OE-S)

The double rail trolleys are supplied with mounted buffers.

NOTICE

The trolley must run smoothly over the whole runway without jamming or increased

friction at the wheel flanges. Increased friction at the flanges due to poor beam quality or

incorrect trolley adjustment may lead to increased wear.

➢

Ensure that the trolley runs smoothly without increased friction at the wheel flanges.

1.

The runway must meet the requirements of ISO 12488-1.

2.

Make sure that the rail joints are even on both running and guide surfaces. Grind

down if necessary.

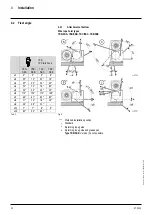

Check track gage

Ø D

a

b min

[in]

[in]

[in]

3.9

0.1…0.2

1.2

4.9

0.1…0.2

1.2

6.3

0.14…0.24

1.2

7.9

0.18…0.28

1.2

Tab. 11

Fig. 20

1.

Check track gage

“S”

on trolley and rail (

Smax

–

Smin = 0.197 in.

)

2.

Check lateral play

“a”

between rail and flange.

3.

“a”

as per Tab. 15, if trolley is positioned symmetrically on runway.

If asymmetrically,

a

left

+ a

right

= 2 × a

.

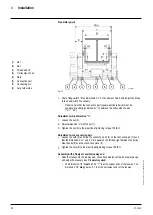

Transport anchor screws

(only on trolleys with wheel diameter

D = 4.9 in.

)

Fig. 21

1.

Remove transport anchor screws

“TS”

.

Bolt buffers and stops

1.

Bolt rubber buffers to trolley or runway end stop.

2.

Fit suitable stops (dimensions see next section).