7

Inspection and maintenance

148

07.2020

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

7.21

Remaining service life

The operating mode and operating time must be established by the owner, see section

1.3 and recorded in the logbook in order to calculate the remaining service life.

After the service life has expired a general overhaul (S.W.P. = Safe Working Period) must

be carried out.

7.21.1

Operating hours counter in SLE load monitor

Fig. 90

The operating hours counter in the SLE load monitor adds up the operating times of the

hoisting mechanism. In order to obtain the used lifetime (remaining service life) in full-

load hours, the operating hours are to be evaluated with the load spectrum data “k”. This

is performed by a competent perso

n within the framework of the annual “periodic

inspection”, see section 1.5.

7.21.2

Multicontroller SMC (optional)

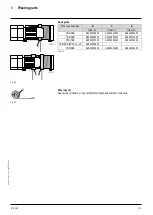

Fig. 91

The Multicontroller SMC has a load spectrum recorder. The load-specific operating hours

of the hoisting mechanism are stored in the load spectrum recorder. The SMC uses this

load spectrum data to calculate the full-load operating hours of the hoisting mechanism.

The remaining service life is calculated from the full-load operating hours determined,

with consideration to the mechanism group. Once the theoretical full-load lifetime has

been reached, this is indicated by continuous flashing of the three yellow LEDs (I, II, III)

on the SMC.

If this is the case, a general overhaul must be performed in accordance with the

manufacturer’s specifications.

The operating hours and the load spectrum data can be read out via this with a PC

(laptop).

NOTICE

Reading out the operating hours counter with the SLE or reading out the load spectrum

data with the SMC does not replace the prescribed tests, including testing the wearing

parts (rope, return sheaves, etc.).