7

Inspection and maintenance

07.2020

113

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

7.13.3

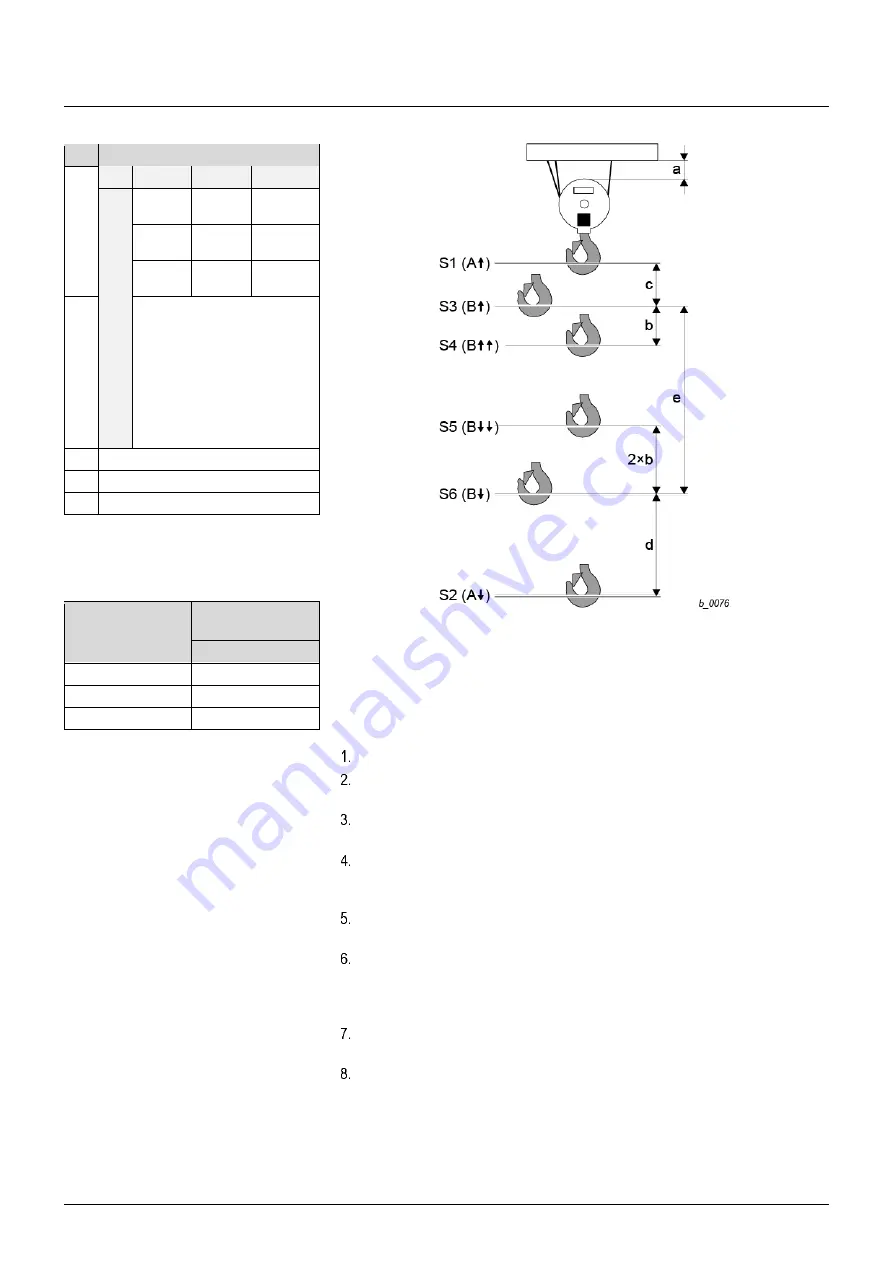

Checking the operational hoist limit switch - version 2 (S3)

Dim.

[in]

a

*1

50 Hz

60 Hz

Reeving

1PS

1PD

5.1

5.9

1

2PS

2PD

2.8

3.1

2

4PS

4PD

1.6

2

4

b

YK

/SK

with

frequen

cy

in

ve

rter

b = V × t × 0.023

ft

V = Hoist speed [fpm]

t = Brake ramp [s]

(Factory setting = 1.5 s

)

Example:

YKC/SKC-L05-

…S2

64

-V

b = 64 × 1.5 × 0.023 = 2.2

ft

c

*1

2.4

d

4.7

e

Effective hook path

*1

With the option

hook operated

hoist limit switch

(see section 4.12),

dimension “a” increases by 3.9

in,

dimension “c” increases in accordance with

the table.

Type

Dimension “c”

enlargement

[in]

YKA/SKA, YKB/SKB

2

YKC/SKC, YKE/SKE

3.9

YKD/SKD

5.9

Actuate the UP-button in the control pendant with caution.

Observe the hoisting movement, until the operational hoist limit switch switches off in

the top hook position (B

).

Prior to reaching the switch-off point (B

), make sure that a reduction to the slow

speed takes place (B

).

The minimum distance “a” + “c” between the hook block and the next obstacle, see

table, or hook aperture “C” (see section

7.15) must be maintained as a minimum,

depending on the dimension at which the hook hangs lower.

With deviations, adjust the geared limit switch again (see section

7.14 Adjusting the

switching points

).

Carefully actuate the DOWN-button in the control pendant whilst observing the

hoisting movement until the operational hoist limit switch switches off in the lower

hook position (B

). Prior to reaching the switch-off point (B

), make sure that a

reduction to the slow speed takes place (B

).

Mainta

in the minimum distance “d” between the switching point (B

) and (A

) (see

figure).

With deviations, adjust the geared limit switch again (see section

7.14 Adjusting the

switching points

).