7

Inspection and maintenance

07.2020

95

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

7.6

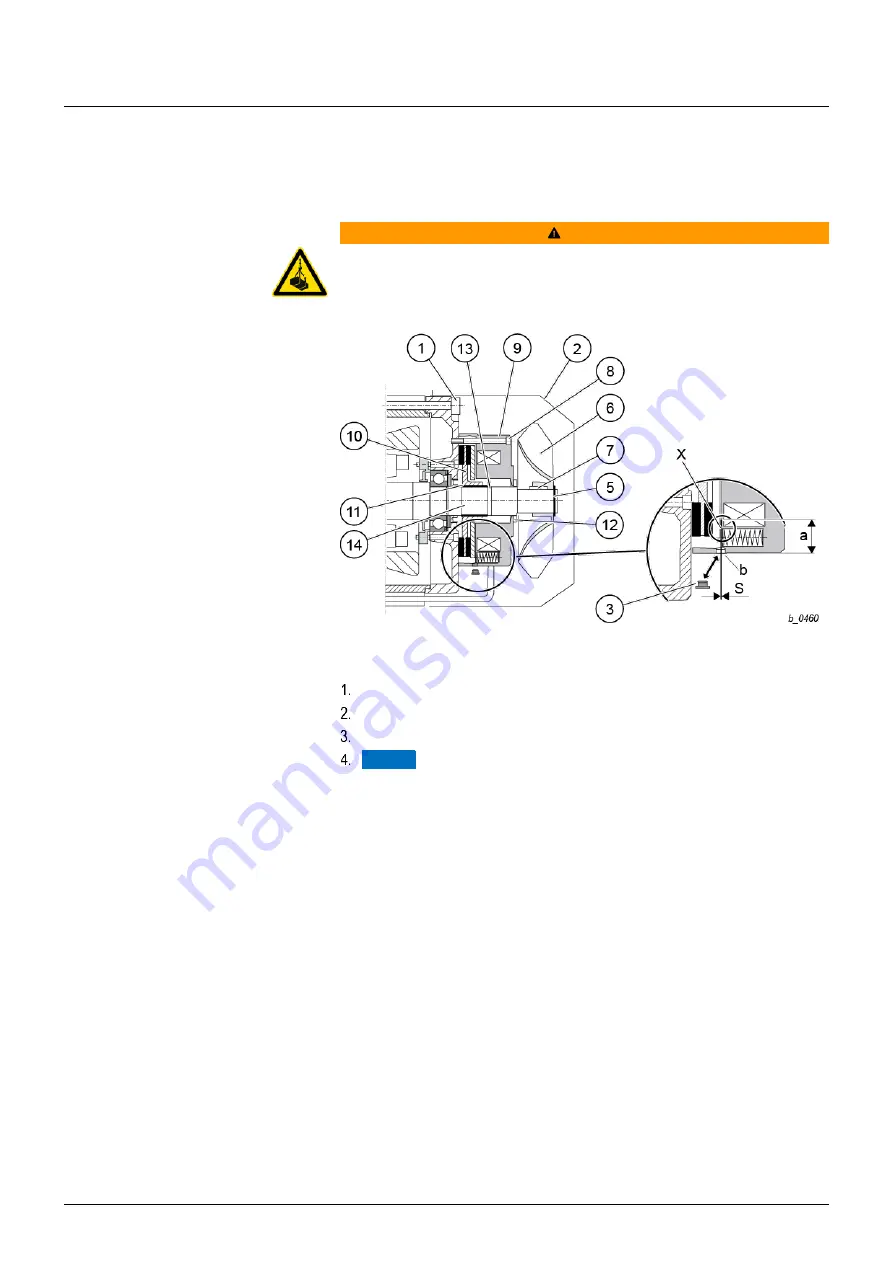

Hoist motor brake (RSM)

This inspection and maintenance is of particularly important to ensure safety.

If brake maintenance is not performed correctly or the brake does not function correctly,

the load may fall!

WARNING

Danger of falling load

Carry out work on the hoist brake only when the hoist is unloaded and the bottom hook

block has been set down.

➢

Switch off the main isolation switch and secure against being switched on again!

(1)

Fastening screws

(2)

Fan cover

(3)

Stopping plug

(5)

Retaining ring

(6)

Fanwheel

(7)

Parallel key

(8)

Fastening screws

(9)

Coil carrier

(10)

Brake rotor

(11)

Hub

(12)

V-ring (IP66)

(13)

Retaining ring

(14)

Motor shaft

Fig. 73

7.6.1

Checking the brake

Remove fan cover (2)

Remove stopping plug (3)

Measure the air gap (S) with a feeler gauge (b).

NOTICE

When measuring, ensure that the feeler gauge (b) is slid up to insertion

depth “a” as a minimum and does

not become caught on the ledge (!). Refer to the

table for the maximum permissible air gap (S). The brake is not readjustable. Once

the max. permissible air gap (S) has been reached, the brake rotor must be replaced.