7

Inspection and maintenance

98

07.2020

ba

-o

.2

.6

.0

-us

-3

.2

-ys

|

A1

18

67

50

1 Re

v A

E

7.7

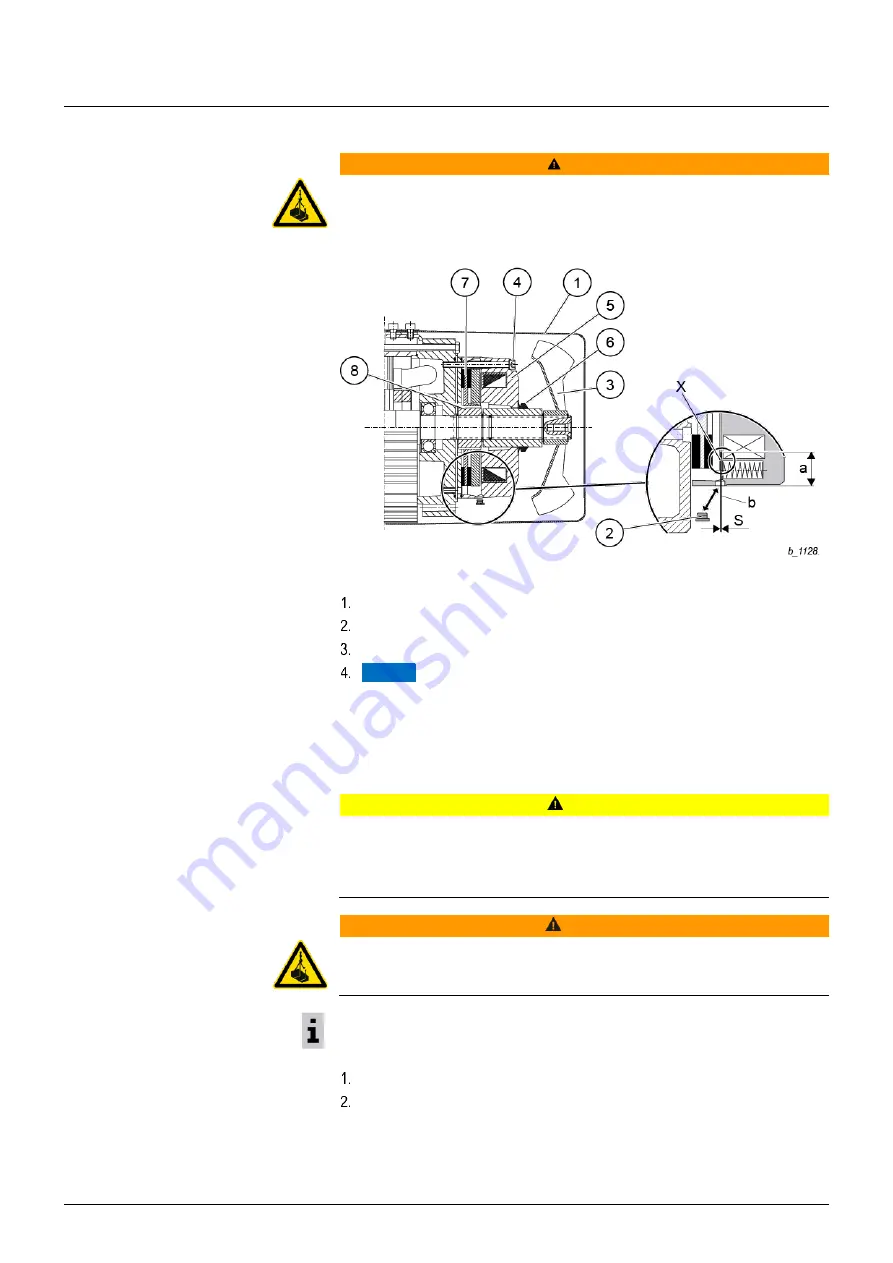

Hoist motor brake (NM) 12/2H…

-MF

WARNING

Danger of falling load

Carry out work on the hoist brake only when the hoist is unloaded and the bottom hook

block has been set down.

➢

Switch off the main isolation switch and secure against being switched on again!

(1)

Fan cover

(2)

Stopping plug

(3)

Fanwheel

(4)

Fastening screws

(5)

Coil carrier

(6)

V-ring (IP66)

(7)

Brake rotor

(8)

Hub

7.7.1

Checking the brake

Remove fan cover (1).

Remove stopping plug (2).

Measure the air gap (S) with a feeler gauge (b).

NOTICE

When measuring, ensure that the feeler gauge is slid up to insertion depth

“a” as a

minimum (see Tab. 28) and does not become caught on the ledge (!). For the

maximum permissible air gap (S) refer to Tab. 28. The brake is not readjustable.

Once the max. permissible air gap (S) has been reached, the brake rotor must be

replaced.

7.7.2

Replacing the brake rotor

CAUTION

Brake dust is hazardous to health.

➢

Do not clean brakes with compressed air, brushes or similar.

➢

Use a vacuum system or a damp cloth to remove brake dust.

➢

If dust develops, wear safety eyewear and a fine dusk mask.

WARNING

With an incorrectly assembled brake rotor, the brake cannot hold the load and the load

will fall. This can result in serious injuries and even death.

➢

Ensure that a competent person carries out the replacement work.

The pressure springs of the brake must always be replaced at the same time.

Remove fan cover (1).

Take off fanwheel (3), remove bushing with V-ring (6).