Page 12

5-4. INSPECT ELECTRICAL CONTROLS. Arrangement of

electrical control equipment varies with the type of control,

physical space and the optional control features ordered with

the hoist.

Note the location in the electrical compartment of the control

circuit fuse, transformer, limit stop switches and the hoist

contactors. Trolley contactors and optional hoist and trolley

fuses may also be located in this compartment on certain

models. (Note: The rope anchor on single reeved hoists is

accessible from this compartment.)

Hoist and trolley fuses and trolley contactors may be located in

electrical compartment located on trolley on certain models.

Use wiring diagram furnished with hoist to determine electrical

components on your hoist; then determine component location

and identity on your hoist.

Be certain that main power switch is locked in open

position before opening hinged access cover on side

of hoist.

WARNING

Check to be certain main power switch is locked in

open position before removing brake cover.

WARNING

a. Open hinged access cover at side of hoist and inspect

wiring and terminals. Terminals should be securely

crimped to wires and insulation sound. Terminal screws

should be tight.

b. Check condition of contactor assembly, transformer, and

upper limit switches.

5-5. INSPECT MOTOR BRAKE AND ACTUATING

MECHANISM.

a. Remove one hex button head cap screw from brake cover

and lift brake cover away from gearcase cover.

b. Unplug electrical leads and loosen set screw in gearcase

cover (Ref. No. 1 in Figure 9-6). Turn actuating mechanism

counterclockwise, by hand or with a plumber’s strap

wrench, and remove from gearcase cover.

c. Check to see that brake plunger moves freely. Inspect for

evidence of overheating or other damage.

d. Replace all worn or damaged parts. Operating spring on

actuating mechanism is color coded for brake torque;

when replacing spring use spring having same color code.

When replacing body assembly, also replace brake

operating spring.

e. Reassemble brake and cover only if further disassembly

to check friction surfaces and hub spline is not required

at this time. Refer to “MOTOR BRAKE ADJUSTMENT’

paragraph 7-2 for adjusting instructions. For further

disassembly proceed to step “f.”

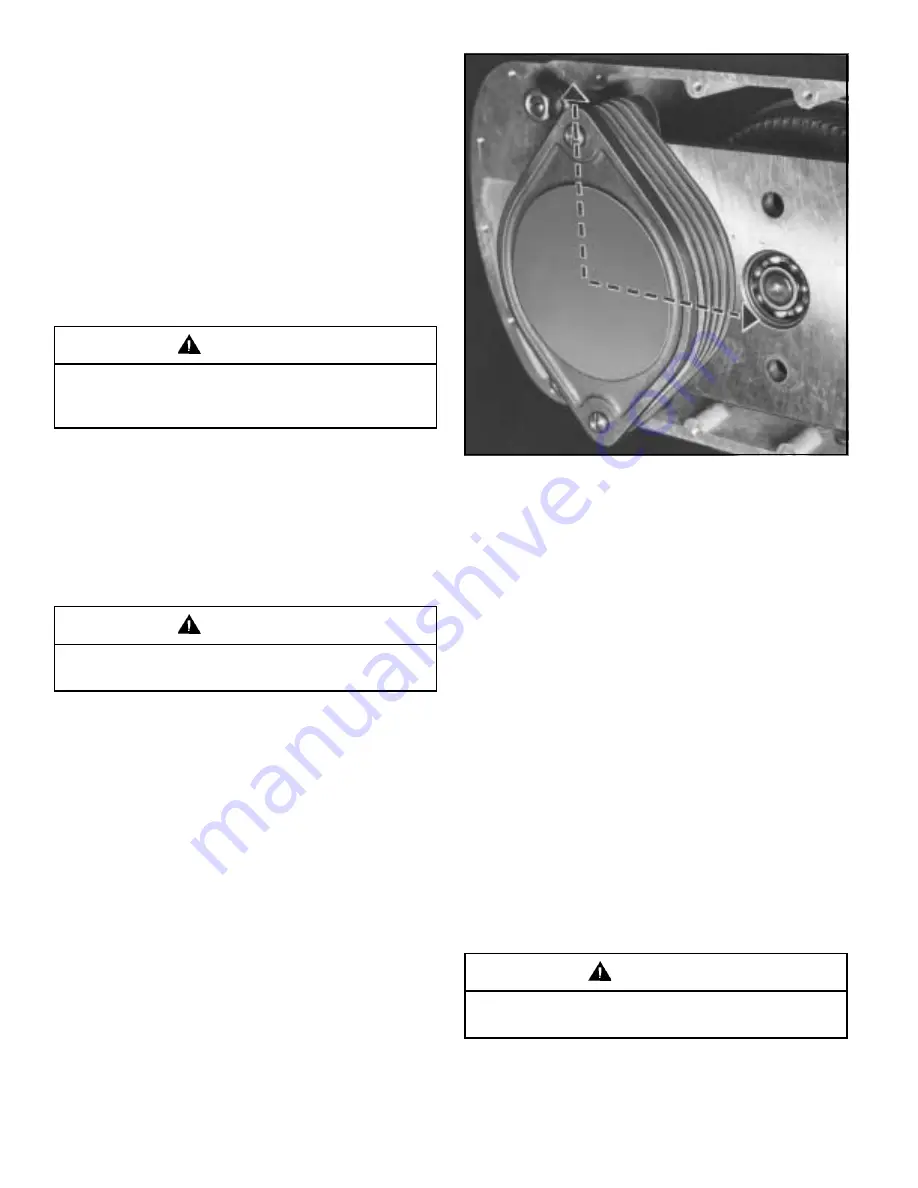

f. To check motor brake friction surfaces (Figure 5-3), drain

oil from gearcase. Disconnect solenoid coil leads. Remove

hex head cap screws securing gearcase cover to

gearcase. Remove gearcase cover and attached motor

brake actuating mechanism from gearcase.

g. Remove retaining rings from the brake pilot studs and lift

off the compression plate. Lift off washer and lining

assemblies, release springs, and motor brake plates. (Note

for reassembly, that two of the washer and lining

assemblies have friction surfaces on one side only and

must be replaced at each end. Three washer and lining

assemblies, with friction surfaces on both sides and

release springs are replaced between the motor brake

plates; see Figure 5-3). Check motor brake plates for

warping, scoring or other signs of deterioration. Also check

spline fit of motor brake plates to the brake hub for

gouging, mushrooming of the plates or other signs of

distress or wear. Replace plates if these conditions are

found. Brake plates which are replaced because of spline

wear should also receive a replacement brake hub. Check

condition of friction material on the washer and lining

assemblies, and replace assemblies if required. Reinstall

brake plates, release springs, and friction washers in

sequence as shown in Figure 5-3 and replace retaining

rings. On the Size 3 hoist it is possible to get the lining

assemblies misoriented. When installed properly the

friction linings will be on a horizontal line (not vertical).

Clean and flush gearcase and replace gearcase cover

using a new gasket. Refill with new lubricant.

5-6. INSPECT MECHANICAL LOAD BRAKE AND GEARING.

Check to be certain main power switch is locked in

open position before removing brake cover.

WARNING

Figure 5-3. Motor Brake Friction Plates

11988

a. To inspect hoist, drain oil from gearcase, remove motor

brake actuating mechanism per Paragraphs 5-5.a and 5-

5.b, remove hex head cap screws from gearcase cover,

and remove gearcase cover.

Summary of Contents for SHAW-BOX

Page 66: ...NOTES ...

Page 67: ...NOTES ...