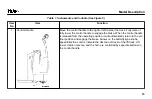

Table 1. Instruments and Controls (See Figure 5) (Continued)

Item

No.

Item

Function

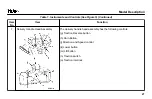

a

Traction Reverse Button

WARNING

The traction reverse button causes rapid acceleration and should not

be used for changing direction.

The traction reverse button is on the end of the control handle. When the

button is pushed, the lift truck will move away from the operator (forks first).

The button can be pushed intentionally or unintentionally. When the button

is released, the traction motor will be turned

OFF

. The traction motor will not

move the lift truck in the direction of the control handle until the control is

reset. To reset, move the speed/direction control to the

OFF

position or

move the handle to the

BRAKE ON

position.

b

Horn Button

The horn operates when the key is in the

ON

position and the horn button is

pushed.

Model Description

19

Summary of Contents for A245

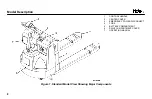

Page 13: ...Figure 4 Warning and Safety Labels Model Description 11 ...

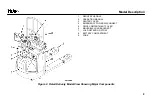

Page 15: ...Instruments and Controls Figure 5 Instruments and Controls Model Description 13 ...

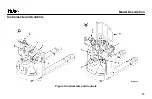

Page 50: ...Figure 9 Putting the Lift Truck on Blocks Maintenance Schedule Maintenance Schedule 48 ...

Page 51: ...Figure 10 Maintenance Points Maintenance Schedule 49 ...

Page 63: ...1 LED 2 LABEL Figure 14 Charger LED s Maintenance 61 ...

Page 70: ...Figure 18 Battery Compartment Maintenance 68 ...

Page 74: ...NOTES 72 ...