Dash Instrument Display System

The instrument display system is composed of a water

temperature sensor, oil temperature sensor, fuel

sensor, oil pressure switch, (on Diesel equipped

forklifts), oil-water separators and other components.

Its function is to detect the operation of the forklift truck

and displays it through the display. This allows the

operator to understand the status of the forklift .

Lighting, sound and alarm system

The system includes a variety of lighting equipment,

signal lights, horn, buzzer, and other components.

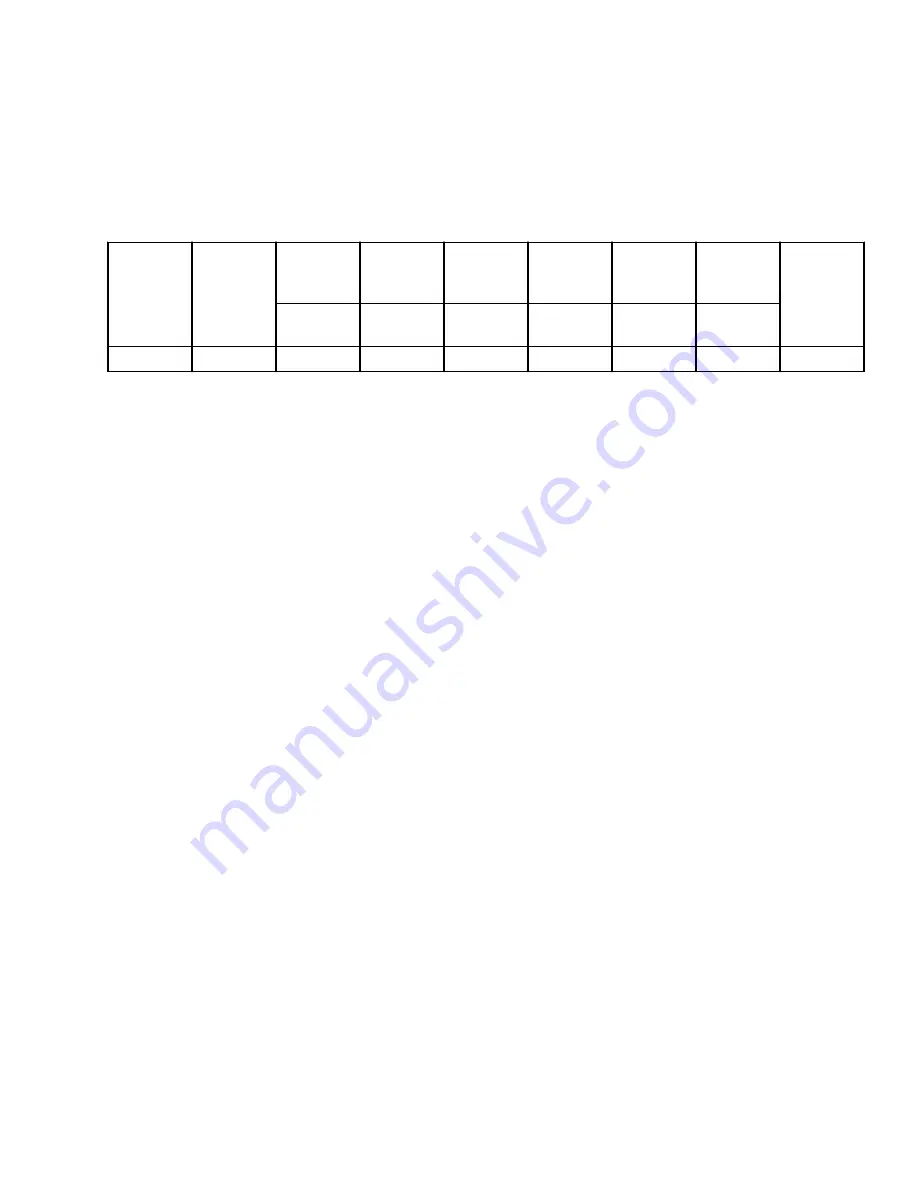

Front

combinatio

n lamp

Front

combinatio

n lights

Rear

combinatio

n light

Warning

light

turning

width

width

brake

reverse

steering

turning

Power (W) 27

10

10

5

21

21

10

21

ELECTRICAL BOX

The electrical box houses fuses and relays. The fuses

are used to protect the circuits to prevent damage due

to short circuit. The relays are used to expand the

switch capacity, making the small-capacity switch able

to control high-power electrical items.

BATTERY

For truck with a maintenance-free battery, pay

attention to the following:

1.

When installing and maintaining, do not touch the

conductor of the battery. This may cause serious

burns.

2.

When charging the battery, the positive and

negative terminals can not be reversed. This will

cause high temperature, burning, fumes or

explosion.

3.

When performing the battery routine

maintenance, wear goggles, rubber gloves and

rubber shoes.

4.

The battery will produce flammable gas, therefore

potential risk of explosion exists. It is necessary to

avoid short circuits, spark occurrence, and any

source of flame.

5.

Prohibit contact with the battery. The battery

electrolyte is dilute sulfuric acid. If contacted with

the skin, please immediately rinse affected area

with water. If contacted with the eyes, rinse

intensively with water and see a doctor as early

as possible.

8000 YRM 2199

Electrical System

65

Summary of Contents for A7S1

Page 4: ......

Page 7: ...TABLE OF CONTENTS Continued Lubrication System 83 PDM Schematics 85 Table of Contents iii ...

Page 8: ......

Page 36: ...Figure 25 2 2 5T Wheel Brakes Brake System 8000 YRM 2199 28 ...

Page 54: ...Figure 43 Oil Circuit of Hydraulic System Hydraulic System 8000 YRM 2199 46 ...

Page 69: ...Figure 58 Two Stage Free Lift and Three Stage Masts 8000 YRM 2199 Lifting System 61 ...

Page 76: ...Figure 61 With NISSAN engine K21 K25 Sheet 1 of 2 Electrical System 8000 YRM 2199 68 ...

Page 77: ...Figure 62 With NISSAN engine K21 K25 Sheet 2 of 2 8000 YRM 2199 Electrical System 69 ...

Page 78: ...Figure 63 With PSI engine Sheet 1 of 2 Electrical System 8000 YRM 2199 70 ...

Page 79: ...Figure 64 With PSI engine Sheet 2 of 2 8000 YRM 2199 Electrical System 71 ...

Page 80: ...Figure 65 With Mitsubishi engine S4S Sheet 1 of 2 Electrical System 8000 YRM 2199 72 ...

Page 81: ...Figure 66 With Mitsubishi engine S4S Sheet 2 of 2 8000 YRM 2199 Electrical System 73 ...

Page 82: ...Figure 67 With Xinchai engine Sheet 1 of 2 Electrical System 8000 YRM 2199 74 ...

Page 83: ...Figure 68 With Xinchai engine Sheet 2 of 2 8000 YRM 2199 Electrical System 75 ...

Page 84: ...Figure 69 With Yanmar engine 92 98 Sheet 1 of 2 Electrical System 8000 YRM 2199 76 ...

Page 85: ...Figure 70 With Yanmar engine 92 98 Sheet 2 of 2 8000 YRM 2199 Electrical System 77 ...

Page 86: ...Figure 71 With Yanmar engine 94 Sheet 1 of 2 Electrical System 8000 YRM 2199 78 ...

Page 87: ...Figure 72 With Yanmar engine 94 Sheet 2 of 2 8000 YRM 2199 Electrical System 79 ...

Page 88: ...Figure 73 Optional Accessories Electrical System 8000 YRM 2199 80 ...

Page 93: ...PDM Schematics 8000 YRM 2199 PDM Schematics 85 ...

Page 94: ......

Page 95: ...8000 YRM 2199 Figure 76 PDM Suitable For All Engines 87 88 blank ...

Page 96: ......

Page 97: ...8000 YRM 2199 Figure 77 PDM With OPS Suitable For All Engines 89 90 blank ...

Page 98: ......

Page 99: ......