5

CPA operating instructions

2. CORRECT OPERATION / INTENDED uSE

Max. load capacity

• Air chain hoists of the CPA series have been developed for lifting and

lowering loads up to the rated capacity. The load capacity (rated load)

indicated on the hoist is the maximum safe working load which must

not be exceeded.

Danger zones

• Do not allow personnel to stay or pass under

a suspended load (Fig. 3).

• A lifted or clamped load must not be left

unattended or remain lifted or clamped for

a longer period of time.

• Start moving the load only after it has been

attached correctly and all persons are clear

of the danger zone.

Attaching the hoist

• The operator must ensure that the hoist is

attached in a manner that makes it possible

to operate the hoist without exposing himself

or other personnel to danger by the unit

itself, the load supporting device or the load.

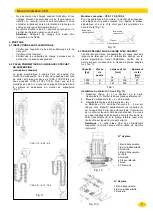

1.3 IDENTIFICATION

The identity plate (Fig. 2) with all important data for exact identification

of the product is fitted on the hoist. If you have any questions with regard

to handling the product, which are not covered by the operating instruc-

tions, please contact:

Yale Industrial Products GmbH

Am Lindenkamp 31 – D-42549 Velbert, Germany

Tel.: +49-2051/600-600 – Fax: +49-2051/600-127

www.yale.de – email: central@yale.de

1.4 SPARK FORMATION

The CPA series is only intended for lifting and lowering loads. In combi-

nation with trolleys, the hoists are also suitable for overhead horizontal

moving of loads.

Any different or exceeding use is considered incorrect and Yale

Industrial Products GmbH will not accept any liability for damage

resulting from such use. The risk is borne by the user/operating

company alone.

Materials subject to danger of friction and impact

Individual sparks can be generated as a result of frictional and/or impact

processes and, as a consequence can be the cause of dangers of ignition

in gases or impact-sensitive dusts.

Increased danger of ignition may emanate from clashing of special mate-

rial pairings. These are non corrosion-resistant steel or cast iron against

aluminium, magnesium or pertinent alloys. This applies especially in case

of rust (also surface rust). Especially at the friction points of the chain and

load hooks rust (surface rust) may occur. For correct operation of the prod-

uct it must therefore be ensured that there is no rust at these wear points

and that in the application area there are no material combinations of the

above-mentioned aluminium alloys and steel (exception: antirust steel) at

possible friction, impact or grinding points; thus spark formation by these

material combinations as a result of mechanical impact can be excluded.

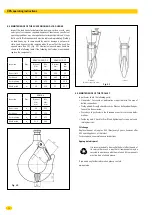

Hand and load chain

Always ensure that hand chain, load chain and the load are guided to

exclude grinding and/or sliding contact with external constructions or com-

ponents. Depending on the degree of corrosion, the conductive discharge

capability of hand chains and/or load chains can worsen to an effect that

it is not adequate any longer. For operation this means that rusty hand

chains and/or load chains must no longer be used.

Note:

The user has to operate the unit to avoid sparking from the hand

chain as well as from the load chain.

For additional safety (e.g. in acetylene atmospheres) and to avoid

sparking by impact and/or friction during operation, the correspond-

ing trolleys are equipped with stainless steel hand chains and the

load and suspension hooks are copper-coated. Trolleys are provided

with solid bronze wheels and buffers.

Optional:

stainless steel load chains.

Air pressure hoses

With a surface resistance of > 10

9

Ω, air hoses used in explosion groups

I, IIA and IIB must have a dia. of ≤ 30 mm, in explosion group IIC, a dia.

of ≤ 20 mm. Otherwise, it is necessary to provide prove that they cannot

be dangerously charged.

Attachment points

Attachment points have to be selected to ensure that the expected forces

can be safely absorbed. The unit must move freely under load in order to

avoid impermissible additional loading.

1.5 EARTHING

Electrostatic dangers of ignition can be avoided by safe earthing. In

zones 1 and 21, earthing of the hoists is required. This can be obtained

via the suspension hook or suspension eye if the hoist is connected to

appropriately earthed parts (earth leakage resistance < 10

6

Ω). The same

also applies for the use of trolleys. Their travel beam must be earthed

by the customer. It must be ensured that trolley wheels and surfaces of

travel rails are not covered with coats of paint as otherwise earth leakage

resistance could reach inadmissibly high values.

The earth connection of the load hook is obtained via the load chain.

Loads have to be earthed, too, for transport. A separate connection to

earth is, for example, necessary when non-conducting lifting tackle are

used. In principle, the entire chain hoist must always be included in the

equipotential bonding.

1.6 TRANSPORT AND STORAGE

For safe transport of the unit, observe the following:

- Do not throw hoists down. Always place them properly on the

ground.

- Hand chains and load chains must be transported in such a way

that knotting and formation of loops are avoided.

- Do not bend the air pressure hoses.

Fig. 3