13

CPA operating instructions

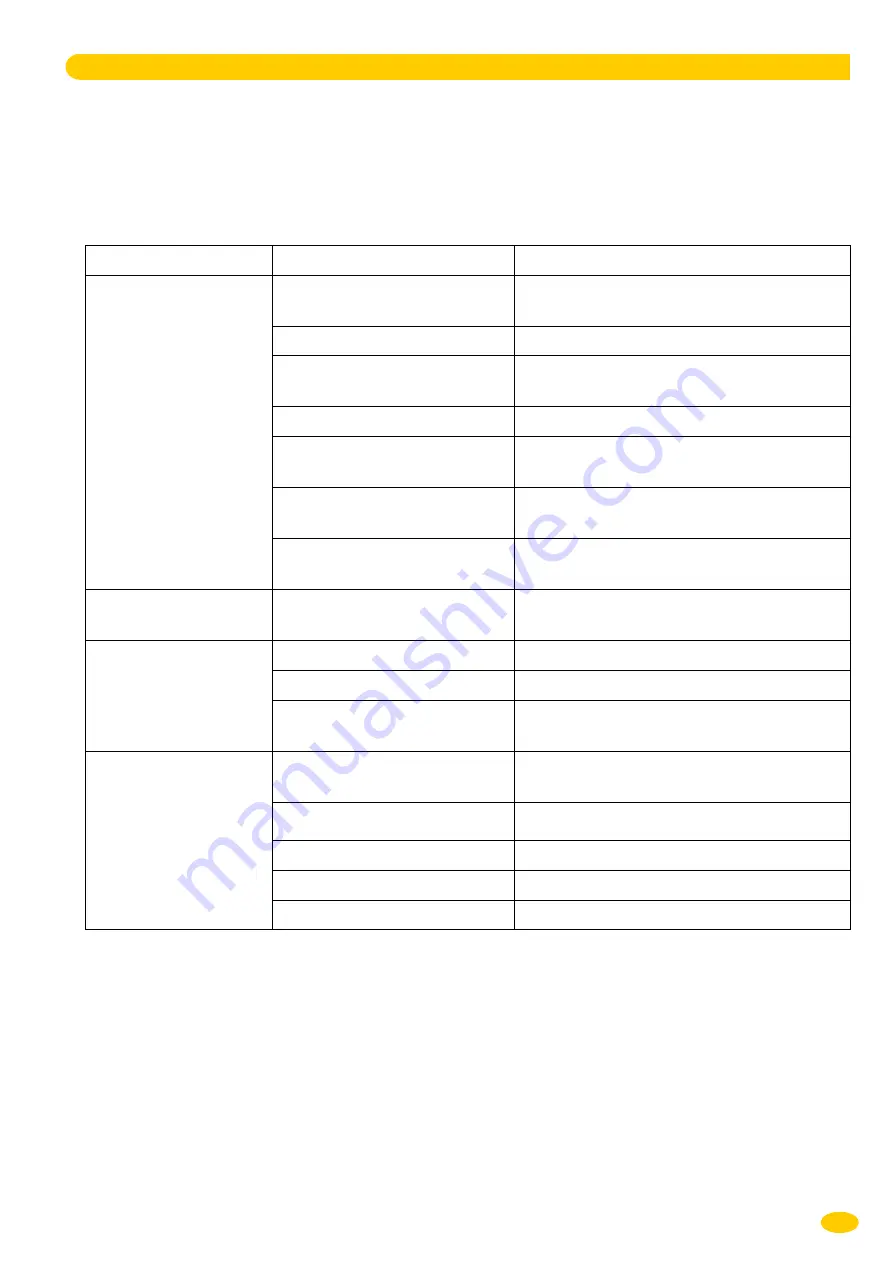

Troubleshooting

This section provides basic troubleshooting information. Specific causes to problems are best identified by thorough inspections performed by personnel

instructed in safety, operation and maintenance of this equipment. The chart below provides a brief guide to common hoist and trolley symptoms, prob-

able causes and remedies.

Symptom

Cause

Remedy

No air supply to hoist or pressure too low.

Check pressure at hoist inlet.

See also page 8, item 4.4 Air pressure connections.

Pendant lever sticking

Check pendant lever and restore free movement.

Pendant malfunction

Check pressure at pendant.

Minimum operating pressure in pendant line is 5 bar.

Hoist will not operate

Hoist is overloaded.

Reduce load to within rated capacity.

Motor is damaged.

Repair or replace. Refer to the maintenance instructions,

“Disassembly of the motor”.

Limit switch sticking.

Check limit switch button moves freely.

Clean and lubricate if sticking.

Brake is not releasing.

Check brake release circuit and pressure at the brake inlet. Minimum

operating pressure is 5 bar.

Load continues to move when hoist is

stopped. UP direction.

Pendant lever sticking.

Check lever and restore free movement.

Load continues to move when hoist is

stopped. DOWN direction.

Pendant lever sticking.

Check lever and restore free movement.

Hoist is overloaded.

Reduce load to within rated capacity.

Brake is slipping.

Check brake springs and brake disc linings for wear.

Refer to the maintenance instructions, “Disassembly of the brake”.

Hoist will not lift rated capacity.

No air supply to hoist or pressure too low.

Check pressure at hoist inlet.

See also page 8, item 4.4 Air pressure connections.

Brake is not releasing.

Check brake release circuit and pressure at the brake inlet. Minimum

operating pressure is 5 bar.

Exhaust is restricted.

Inspect vents and clean or replace muffling material.

Motor is damaged.

Check motor bearing and wear of vanes.

Hoist is overloaded.

Reduce load to within rated capacity.