10

All units with two or more chain strands must be inspected

before every operation for twisted or kinked chains. Chains

on 2-strand units may become twisted if the bottom block

is rolled over . If a strand is twisted disconnect it from the

hoist and re-thread it correctly . In some cases it may be

necessary to remove the last link.

8. Before initial operation lubricate the unloaded chain and

test all hoist functions under a no-load condition.

Inspect the hooks for deformation, damage, surface cracks,

wear and signs of corrosion as required but

. Adverse working conditions may dictate shorter

periods. Hooks that do not fulfill all requirements must be

replaced immediately, Welding on hooks to compensate

for wear or damage is not permissible. Hooks must be

replaced when the mouth of the hook has opened more

than 10% (Fig.14) or the nominal value of other dimensions

has decreased by 5% due to wear . Nominal dimensions

and wear limits are shown in the following table.

In particular check following parts:

• Side plate

For cracks or deformation in particular around the areas of

Visually check for cracks and wear on trolley wheel flanges.

In particular around threaded areas for cracks.

Check nuts, screws and locking devices for tightness.

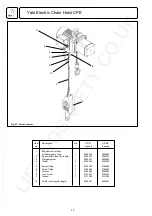

6.6 Electric chain hoist in general

In particular check following parts:

• Threaded connections in general

Check all nuts, screws and locking devices for tightness.

Ensure the chain container is securely fastened. Check

(Connection between hoist and suspension hook resp.

trolley) Check for cracks or wear. Ensure all safety devices

The overload protection device ( slipping clutch) is factory

10% of the rated capacity and can be checked

by lifting a suitable load. If the device slips at the rated

• Increase the moment of friction by turning the straining

screw (45) in clockwise direction.

• Re-check the adjustment with a suitable load.

• Lock the straining screw (45) with the threaded pin (9).

The gearbox is practically maintenance-free. Service is

therefore reduced to changing the oil.

The oil (approx. 0,3 l) is to be changed every 5 years or at

the latest after 400 operating hours.

Disassemble the gear cover (51) by removing the cylinder

screws (52) and unscrew the screw plug (44). Place the

hoist horizontally and turn so that the oil can drain from the

fill hole into a suitable container (approx. 30 minutes).

Replenish the gearbox oil. W e recommend a mineral oil

viscosity class ISO-VG 460, e.g. FINA GIRAN L 460. Finally

re-adjust the overload protection device.

The gearbox has oil lubrication

1. Pull the coupling (50) of f the gear shaft (35). Loosen

screws (52) and remove gearbox cover (51).

2. Remove screw plug (44) and seal (45).

3. Place gearbox upside down and drain oil from the fill

hole into a suitable container .