5

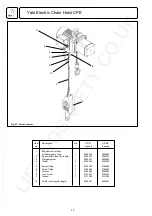

Electric chain hoist with trolley

The trolleys are supplied pre-assembled for beam width A

or B (see table below). This is indicated on the name-plate.

Before installation ensure that the trolley width is correct for

The load must always be seated in the saddle of the hook.

Never attach the load to the tip of the load hook. This also

applies to the suspension hook (Fig. 10).

Inspect the traverse (for trolleys)

Inspect the traverse for correct assembly and visually check

for external defects, deformations, superficial cracks, wear

or signs of corrosion. Especially make sure that the roll pins

are properly fitted to the centre traverse (Fig. 12).

Check adjustment of trolley width

On chain hoists without suspension hook (CPE-VTP/G/E)

check that the clearance between the trolley wheel flange

and the beam outer edge is equal on both sides and within

the tolerances given (see page 6, 2. - 3.). Enlarging the

clearances, e.g. to enable the trolley to negotiate tighter

3. ASSEMBLY

3.1 Inspection before assembly

- Check that the capacity indication on hoist and bottom block

3.2 Electric chain hoist with hook suspension

The suspension hook is connected to the hoist with two

suspension pins. Independent of how the hoist is reeved the

load hook must always hang vertically under the suspension

hook. In 1-strand configuration the suspension hook is to be

installed centred on the marking "1/1", in 2-strand

configuration centred on the marking "2/1" (see Fig. 11).

Secure the two suspension pins with locking plate

Selection and calculation of the suitable suspension point