9

The Yale load chain is grade 80 chain with the dimensions

11 x 31 mm. The CPE electric hoists are specially designed

to use this type of chain. For this reason only chains that

have been approved by the manufacturer may be used in

The load chain is to be lubricated before initial operation

and every 3 months but the latest after 200 operating hours.

Adverse working conditions, e.g. excessive dust or con-

tinued heavy duty can dictate shorter periods between

• Before the chain is lubricated it must be cleaned. Flame

cleaning is forbidden. Use only cleansing methods and

agents that do not corrode the chain material. Avoid

cleansing methods that can lead to hydrogen brittleness,

e.g. spraying or dipping chain in caustic solvents. Also avoid

surface treatments that can hide cracks and flaws or other

surface damage.

• The chain must be lubricated in a no-load condition so

that lubricant can enter between the links, e.g. by dipping in

oil.

• Motor oil of the voscosity 100, e.g. Shell Tonna T68 can

be used to lubricate the chain. For very dusty applications

Inspecting the load chain for wear

Load chains must be inspected every 3 months or the latest

after 200 operating hours (see VBG 8 § 27 or local regu-

Visually inspect the chain over its full length for defor-

mation, cracks, flaws, elongation, wear or corrosive pitting.

Link chains must be replaced when the nominal thickness

"d" on any part of the chain has been reduced by more than

10% or when the pitch "t" is elongated by more than 2%

or over 11 pitches (11 x t) by 2%. Nominal dimensions and

wear limits are shown in the following table.

Chains that do not fulfil all requirements must be replaced

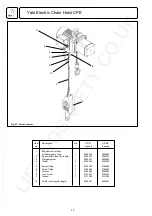

Replace the load chain

1-strand design

Remove the circlip with suitable pliers. Raise the swivel

tube in the direction of the chain and tap out the chain bolt

Do not damage the chain bolt bore.

Remove the 2 screws. The chain is now free.

3. Fitting the new chain

Cut the second to last link open on the loose end of the

load chain to form a "C". Remove the last link and connect

the new chain. The new chain must be fitted so that the

welds on the standing links face towards the chain guide

and away from the load sheave. Operate the hoist in the

lowering direction to feed the chain through the hoist.

4. Fitting lower block and chain end stop

Slide the end buffers over the loose ends of the load chain

and refit bottom block and chain end stop. The chain end

stop must be fitted so that at least 1 link remains free (see

Fig. 1)

5. Before initial operation lubricate the unloaded chain and

test all hoist functions under no-load condition.

1. Remove the chain anchor bolt

The chain anchor bolt is situated on the underside of the

hoist body. With an Allen key remove the grub screw that

serves as locking device. Tap out the chain anchor bolt

with a drift from the other side.

Do not damage anchor bolt or bore.

2. Pull the load chain through the bottom block and remove

the chain end stop.

3. Fitting the new chain

Cut the second to last link open on the loose end of the

load chain to form a "C". Remove the last link and connect

the new chain. The new chain must be fitted so that the

welds on the standing links face towards the chain guide

in the housing. Operate the hoist in the lowering direction

to feed the chain through the hoist.

4. Replace chain end stop

Slide the buffer pad over the loose end of the load chain

and refit the chain end stop ensuring that at least 1 link

remains free (see Fig. 1).

5. Fitting the chain anchor bolt

Inspect the chain anchor bolt for flaws, cracks or burrs.

Enter the last link of the other load chain end into the slot in

theunderside of the hoist body . Attention: The chain must

not be twisted. Now enter the chain anchor bolt through the

side bore. Move the last link back and forth while entering

the chain anchor bolt to ensure that it is not trapped and

damaged by the anchor bolt. Secure the anchor bolt with

the grub screw.

6. Assemble the bottom block

Check the idler sheave for damage. Position the load chain

over the idler sheave ensuring that the welds on the standing

links face away. Grease the needle bearings in the bottom

block halves. Place the load hook assy in the slot provided

in one of the bottom block halves and push the complete

unit onto the idler sheave. Ensuring that the buffer pad is

situated correctly in its groove replace the second bottom