Yale

Electric Chain Hoist - CPV/F

®

12

8.5 MAINTENANCE TROLLEYS

In particular check the following parts:

• Side plate: For cracks or deformation in particular around

the areas of screwed connections.

• Trolley wheels: Visually check for cracks and wear on trolley

wheel flanges. Grease the transmission.

• Crossbars: In particular around threaded areas for cracks.

• Fasteners: Check nuts, screws & locking devices for tightness.

8.6 MAINTENANCE OF OVERLOAD PROTECTION DEVICE

Overload protection device

The unit is equipped with an overload protection device as

standard. This device is factory set to 135% +/-10% of the rated

capacity and prevents overloading of the hoist during lifting of

loads. Adjustment and testing of the overload device may only

be carried out by authorised competents persons.

The force-limit factor according EN 14492-2:2006 amounts

o

DAL

= 1.35. The maximum force occurring when the rated

capacity limiter operates will be calculated as:

F

LIM

= (

o

DAL

x m

RC

+ m

H

-m

RC

) x g

o

DAL

= 1.35

m

RC

= Rated capacity of the hoist (kg)

m

H

= Hoist load (kg)

Hoist load m

H

: Load which includes all the masses of an equal

load to the rated capacity of the hoist, the hoist medium and

the fixed load lifting attachments, e.g. hooks, grabs, magnets,

lifting beams, vacuum lifters.

g = Acceleration due to gravity (9.81) m/s

2

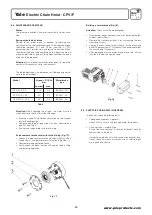

Adjustment of overload device (Fig. 16.1)

Attention:

The adjustment of the overload device device may

only be done by authorised, competent personnel.

Attention:

During this job, the hoist remains operable which

can result in danger of injury by rotating parts.

• Loosen the four socket screws (1) of the fan guard (2).

• Take off fan guard (2) and remove snap ring (3), fan (4) and

key (5).

• Loosen the adjusting nut (6) with a pin type face wrench acc.

to DIN 3116 in anti-clockwise direction until blocked.

• Turn the adjusting nut in a clockwise direction, until the test

load is raised.

Attention:

The max. operating time of the overload device is

60 seconds. Thereafter, the unit has to cool down to room

temperature (minimum of 20 minutes).

• Reassemble in opposite sequence.

8.7 MAINTENANCE OF GEARBOX

The gearbox is practically maintenance-free. Service is therefore

reduced to changing the oil.

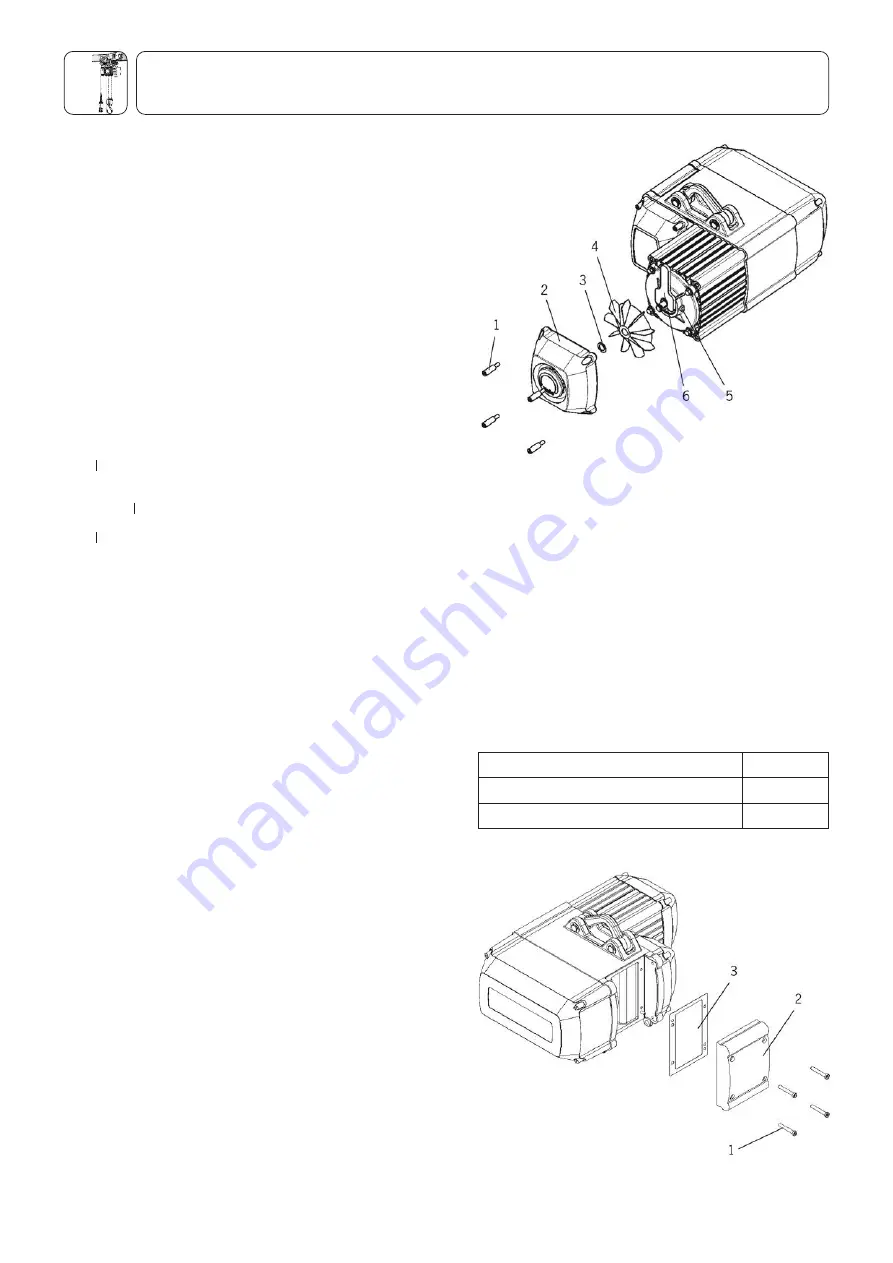

Oil change (Fig. 16.2)

The gearbox oil should be changed after every 10 years,

however, latest after 800 operating hours (oil volume see table 4).

Attention:

During oil change the electric power supply must be

shut off.

Disassemble the gear cover (item 2) by removing the cylinder

screws (item 1). Place the hoist horizontally and turn so that

the oil can drain from the fill hole into a suitable container

(approx. 30 mins). Replenish the gearbox oil. We recommend

a mineral oil viscosity class ISO-VG 320, e.g. FINA GIRAN L 320.

Finally, re-adjust the device with new gasket.

Fig. 16.1

Fig. 16.2

Tab. 4

Model Oil volume

CPV/F 2-8, 5-4, 5-8, 10-4 0.3 litre

CPV/F 10-8, 20-4 0.3 litre

Yale

CPV/F

®