Yale

Electric Chain Hoist - CPV/F

®

5

www.yaleproducts.com

On single fall units, the suspension bracket is installed with the long

bracket side to the right, on dual fall units with the long bracket side

to the left (see Fig. 11).

Attention:

Do not forget to fit the lock washers after installation of

the suspension bracket.

The load bearing structure must be calculated to safely accept all

operational forces.

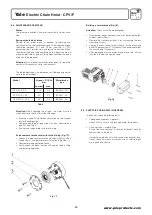

4.3 ELECTRIC CHAIN HOIST WITH TROLLEY

The trolleys are supplied pre-assembled for beam width A or B (see

table below). This is indicated on the name-plate. Before installation

ensure that the trolley width is correct for the intended carrying beam.

Assembly of the trolley (see Fig. 12)

1.

Unscrew the locking nuts (item 9) and hex. nuts (item 2) from

the crossbars (item 1) and remove both side plates (item 6) from

the trolley.

2.

Measure flange width of the beam (Fig. 12-measurement "b").

3.

Adjust measurement "B" between the shoulders of the round

nuts (item 5) on the threaded crossbars (item 1). Ensure that the

4 bores in the round nuts face towards the outside. Adjust the

measurement "B" to equal measurement "b" plus 4mm.

Measurement "A" must be 2 mm on either side and the

suspension traverse (item 4) must be centred between the

round nuts.

4.

Replace one side plate (item 6), ensuring that the roll pins (item

8) engage into one of the bores in the round nuts (item 5). To

achieve this, it may be necessary to rotate the round nuts slightly.

5.

Replace the washers (item 3) and tighten the hex. nuts (item 2).

Screw on the locknuts (item 9) fingertight and tighten a further

1/4 to 1/2 turn.

Attention:

The locknuts must always be fitted.

6.

Loosely replace the second side plate (item 6) on the cross bars

(item 1). The washers (item 3), hex. nuts (item 2) and locknuts

(item 9) can be fitted loosely.

7.

Raise the complete pre-assembled trolley to the carrying beam.

No. Description

1.

Crossbar

6. Side plate

2 .

Hex. nut

7. Trolley wheel

3 .

Washer

8. Roll pin

4.

Centre traverse

9. Locknut

5.

Round nut

Fig. 12

Fig. 11

Beam range

Flange range

Flange thickness

mm

mm

minimum

maximum

maximum

A

98

180

27

B

180

300

27

Tab. 1

Yale

CPV/F

®