Yale

Electric Chain Hoist - CPV/F

®

9

www.yaleproducts.com

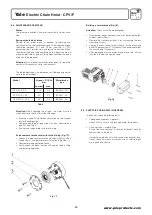

Attaching the load

Attach the load to the hoist using only approved and certified

slings or lashing devices. Never use the load chain as sling

chain. The load must always be seated in the saddle of the

hook. Never attach the load to the tip of the hook (Fig. 10). Do

not remove the safety catch from the load hook.

Lifting / lowering the load

The load is lifted by depressing the -button, it is lowered by

depressing the -button. For hoists with two speeds: The first

stage of button depression activates the slow speed, further

depression activates the faster speed. In order to raise the load,

always use the lowest available lifting speed. The chain must be

loaded at this speed and may not lie slack on the floor. Use the

slow speed for short periods only. Do not use the chain ends

stop as operational limit device (see Fig. 1).

Emergency stop

All movement can be immediately halted by depressing the red,

mushroom shaped button on the pendant control.

Attention:

Operating the red emergency button does NOT

automatically disconnect the mains supply to the hoist or

trolley. To release the emergency stop, rotate the button in an

anti-clockwise direction.

End limit switch

This hoist is provided with an end limit switch for the lowest and

highest hook position as standard. This limit switch is a safety

device and may not be used as operational limiting device.

8.

SERVICE

•

Service and inspections may only be carried out by a

competent person.

• The inspection must determine that all safety devices are

present and fully operational and covers the condition of the

hoist, lifting gear, accessories and supporting constructions.

• The Yale electric chain hoist CPV/F conform to FEM group

1Am, in accordance with FEM 9.511. This results in a theoretical

service lifetime of 800 resp. 400 operating hours under full load.

This is equivalent to 10 years under normal operating

conditions. After this period the hoist requires a general

overhaul.

Further information is contained in BGV D6 rep. FEM 9.755.

Attention:

Maintenance work requires subsequent function

testing with nominal load.

8.1 DAILY CHECKS

1. Visually check the pendant control switch and cable for

damage.

2. Function test of brake.

3. Function test of end limit switch.

4. Electric chain hoists with trolley:

• Check that the trolley runway is free from obstructions.

• Check that the end stops on the trolley runway are fitted

and secure.

t

t

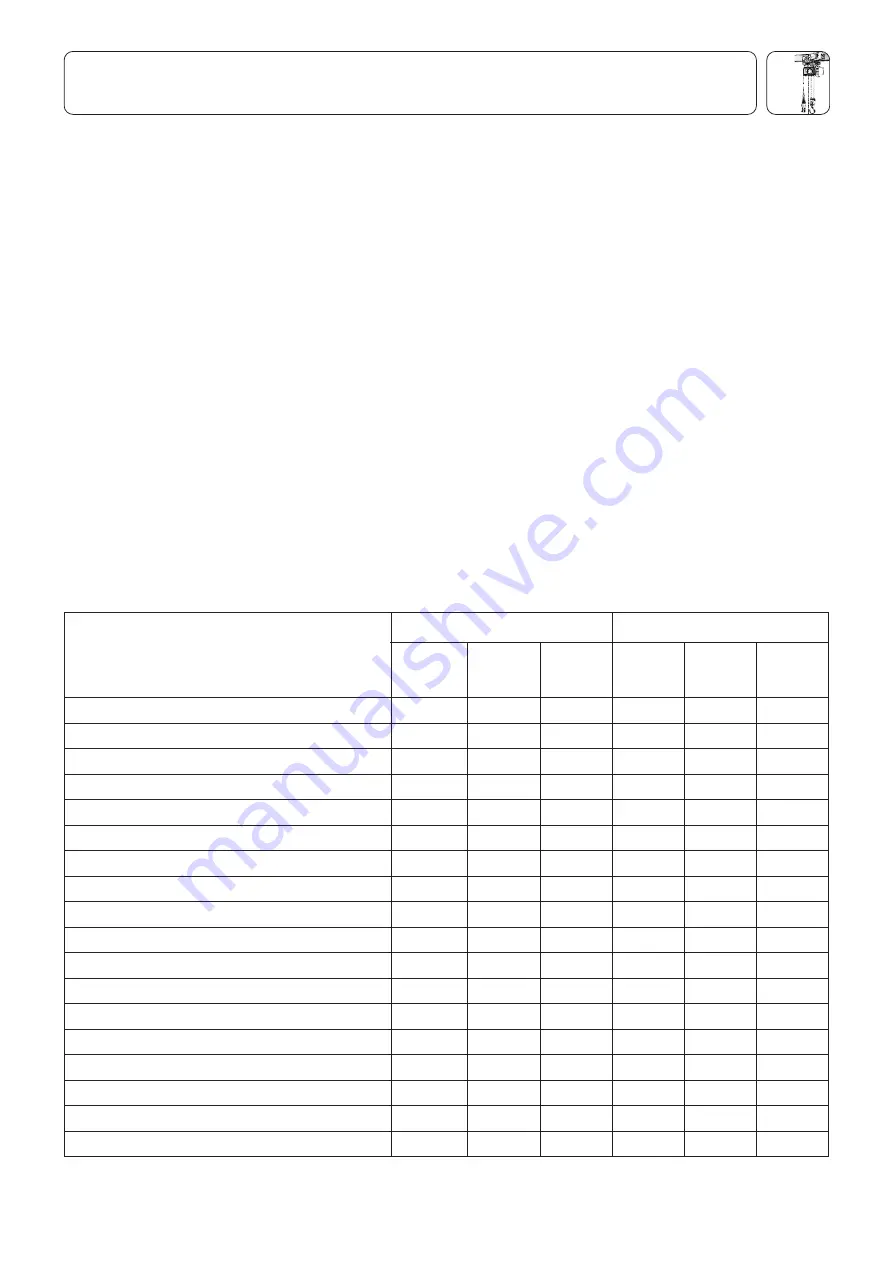

Initial checks

Periodical checks

INSPECTION AND MAINTENANCE

during

after 50

after 200

after 200

commissioning operating

operating

daily

operating

annually

hours

hours

hours

Lubricate load chain.

•

•

•

•

Pendant control and support wire.

•

•

•

Check oil level.

•

•

•

Function test of brake.

•

•

Function test of end limit switch.

•

•

Function test of overload device.

•

•

Electrical installation and power supply.

•

•

Check for wear in chain drive.

•

•

•

Inspect chain bolts for cracks.

•

•

Inspect susp. bracket and load hook for cracks/deformation.

•

•

Check screwed connections for tightness.

•

•

Inspect trolley components for cracks/deformation.

•

•

Oil change.

•

•

Inspect motor and transmission of hoist.

•

Inspect motor and transmission of trolley.

•

Adjustment of overload device.

•

Adjustment of brake.

•

Lubricate geared trolley drive.

•

Yale

CPV/F

®