•

ERP22-35VL (ERP045-070VL) (A976)

•

ERP15-20VT (ERP030-040VT) (G807)

•

ERP16-20VF (ERP30-40VF) (A955)

•

ERP40-50VM, ERP50-55VM6 (ERP080-120VM, ERP100VML) (A985)

•

ERC40-55VH (ERC80-120VH) (A938)

See

Main Control Valves

2000YRM1439,

for lift truck models

•

ERC16-20VA (ERC030-040VA) (A969)

See

Main Control Valves

2000YRM1520,

for lift truck models

•

ERP13-15VC (ERP025-030VC) (B888)

See

Diagnostic Troubleshooting Manual

9000YRM1377 for lift truck models

•

ERP80VN, ERP80VN9, ERP90VM (A410)

4

With no load on the forks, raise them, if they are not already raised.

5

When prompted, move the lever toward the mast, the A direction, until the forks begin to creep. Creep

means moving the forks as slowly as possible. Press the

Enter Key

and the system records the valve

reading.

6

When prompted, move the lever toward the rear of the truck, the B direction, until the forks begin to

creep and press the

Enter Key

. The system records the valve reading. Steps 5 and 6 provide the

hydraulic input for function 1.

NOTE:

If a valve reading is not within the acceptable range, an abort message appears. Press any

key to continue.

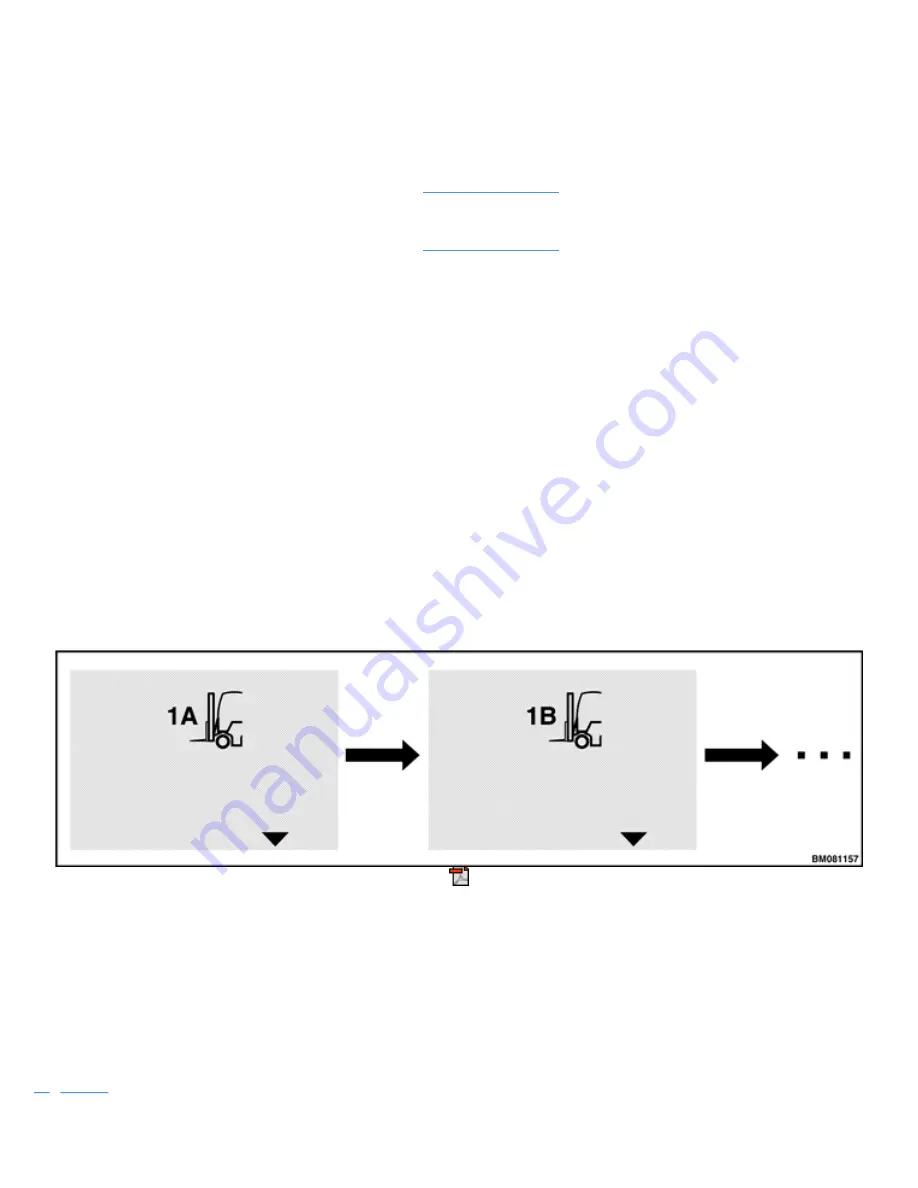

7

Continue the process for functions 2, 3, and 4 as prompted by the system. The system records the valve

readings for each function, and when this calibration process is completed, returns to the Calibration

Menu.

Figure 32. E-Hydraulic Valves

STEERING WHEEL CENTER POINT CALIBRATION

The steering wheel center point is the position to which the system adjusts the steering wheel while the lift

truck is being driven straight ahead.

NOTE:

This calibration must be done by a supervisor or service technician and is only available on

trucks equipped with the Synchronized Steering function.

shows the screen display during a Steering Wheel Center Point calibration.

Summary of Contents for ERC030VA

Page 8: ...Figure 3 Supervisor Flowchart Sheet 1 of 4 ...

Page 9: ...Figure 3 Supervisor Flowchart Sheet 2 of 4 ...

Page 10: ...Figure 3 Supervisor Flowchart Sheet 3 of 4 ...

Page 11: ...Figure 3 Supervisor Flowchart Sheet 4 of 4 Table 1 Supervisor Menu Flowchart A B C D E F G H ...

Page 21: ...Hydraulics Icon Alert Screens Cycle the Key Secure Battery Release Park Brake ...

Page 22: ...Operator Out of Seat Release Pedal Release Hydraulic Input Traction Switch ...

Page 23: ...Hydraulic Switch Temperature Too High Lift Limit Charge Battery ...

Page 26: ...Display Title Screen Status Title Screen Truck Setup Title Screen ...

Page 105: ...Figure 71 Steering Wheel Number of Turns Valid Entry ...