Service Brakes

Brake Fluid Level

WARNING

Small amounts of water in the brake system can cause

reduced braking performance if the water reaches the

wheel cylinder area. Do not allow water entry, ensure that

the sealed reservoir lid is properly replaced.

If the brake system has a power assist (or boost), braking

will be more difficult if the engine is not running.

On lift trucks with wet brake drive axles, only use Dexron

III oil from sealed container in the master cylinder.

On lift trucks with dry brake drive axles, only use SAE

J-1703 (DOT 3) brake fluid in the master cylinder.

Loss of fluid from the brake fluid reservoir indicates a

leak. Repair the brake system before using the lift truck.

Replace the brake fluid in the system if there is dirt or

water in the system.

Failure to observe the above warnings could result in

death or serious injury.

There is an indicator light on the Display Switch Cluster for

the brake fluid. The red light is

ON

when the key switch is in

the

START

position or the Power

ON/OFF

button is pressed,

and must go

OFF

when the engine is running. If the light is

ON

when the engine is running, the brake fluid level in the

reservoir is too low.

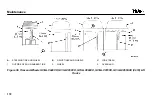

Operation, Check

Check the operation of the service brakes. Push on the

inching/brake pedal. The service brakes must be applied

before the inching/brake pedal reaches the floor plate. The

pedal must stop firmly and must not move slowly down after

the brakes are applied. The service brakes must apply

equally to both drive wheels. The service brakes must not pull

the lift truck to either side of the direction of travel when they

are applied. The service brakes are automatically adjusted

when the transmission is in reverse and the lift truck is moving

and the brakes are firmly applied. Full application of the

inching/brake pedal applies the service brakes and puts the

transmission in

NEUTRAL

.

Lift trucks with a Foot Directional Control pedal:

when the

inching/brake pedal is fully applied, the engine can be star-

ted.

Maintenance

159

Summary of Contents for GDP040-070VX

Page 81: ...Figure 12 Seat Adjustment Full Suspension Operating Procedures 79 ...

Page 113: ...Figure 17 Kubota 2 5L LPG Engine Maintenance and Lubrication Points Maintenance Schedule 111 ...

Page 169: ...Figure 37 LPG Tank and Bracket Maintenance 167 ...

Page 203: ...Spacer 5 15 4 15 2 15 1 15 11 14 ...