Crankshaft and Main Bearings Repair

600 YRM 496

Crankshaft and Main Bearings Repair

REMOVE

1.

Remove bracket for cooling fan.

2.

Remove six capscrews and plate from crankshaft

pulley. Remove six capscrews that hold crankshaft

pulley to timing pulley.

3.

Remove capscrew from timing pulley. Install special

tool on crankshaft to remove timing pulley. Rotate

tool until it touches front of crankshaft. Hit tool with

hammer to loosen timing pulley. Remove pulley,

dowel pin, and tapered ring. Remove tool.

4.

Remove oil pan and oil strainer.

5.

Remove rear cover. Remove front cover with oil

pump.

6.

Remove caps for connecting rods. Put identification

mark on each cap so they will be installed in correct

location.

7.

Before removing crankshaft, measure clearance

between crankshaft and flange of center main

bearing.

See Figure 26.

Push crankshaft fully

forward before making measurement.

Maximum clearance is 0.30 mm (0.012 in.). If clear-

ance is greater than specification, replace center

main bearing or crankshaft.

1.

CENTER MAIN BEARING

Figure 26. Crankshaft Clearance Measurement

8.

Put identification marks on bearing caps. Loosen

capscrews for main bearing caps in steps. Then

remove capscrews, caps, and crankshaft.

INSPECT AND REPAIR

Crankshaft

1.

Inspect crankshaft for wear, cracks, or other dam-

age. Replace crankshaft if it has cracks.

2.

Use micrometer to measure diameter of journals for

crankshaft. See Figure 27. Make measurement at

several locations for each journal. Correct dimen-

sions for journals are as follows:

Main Journal Diameter - 59.937 to 59.995 mm

(2.3597 to 2.3620 in.)

Connecting Rod Journals - 50.940 to 50.955 mm

(2.0055 to 2.0061 in.)

Rear Oil Seal Surface - 89.946 to 90.000 mm

(3.5412 to 3.5433 in.)

Front Oil Seal Surface - 33.961 to 34.000 mm

(1.3371 to 1.3386 in.)

If measurements are less than specifications, grind

crankshaft and install undersize bearings.

3.

Check crankshaft for straightness. See Figure 27.

Put front and rear journals in V blocks and rotate

crankshaft one complete turn. Maximum amount

that dial indicator should indicate is 0.03 mm

(0.0012 in.).

4.

Check oil passages crankshaft. Make sure pas-

sages are clean and have no restrictions.

Main Bearings

NOTE: Do not clean main bearings. If any bearings are

too dirty, replace all main bearings.

1.

Inspect main bearings for damage.

If any main

bearing is damaged, all main bearings must be re-

placed.

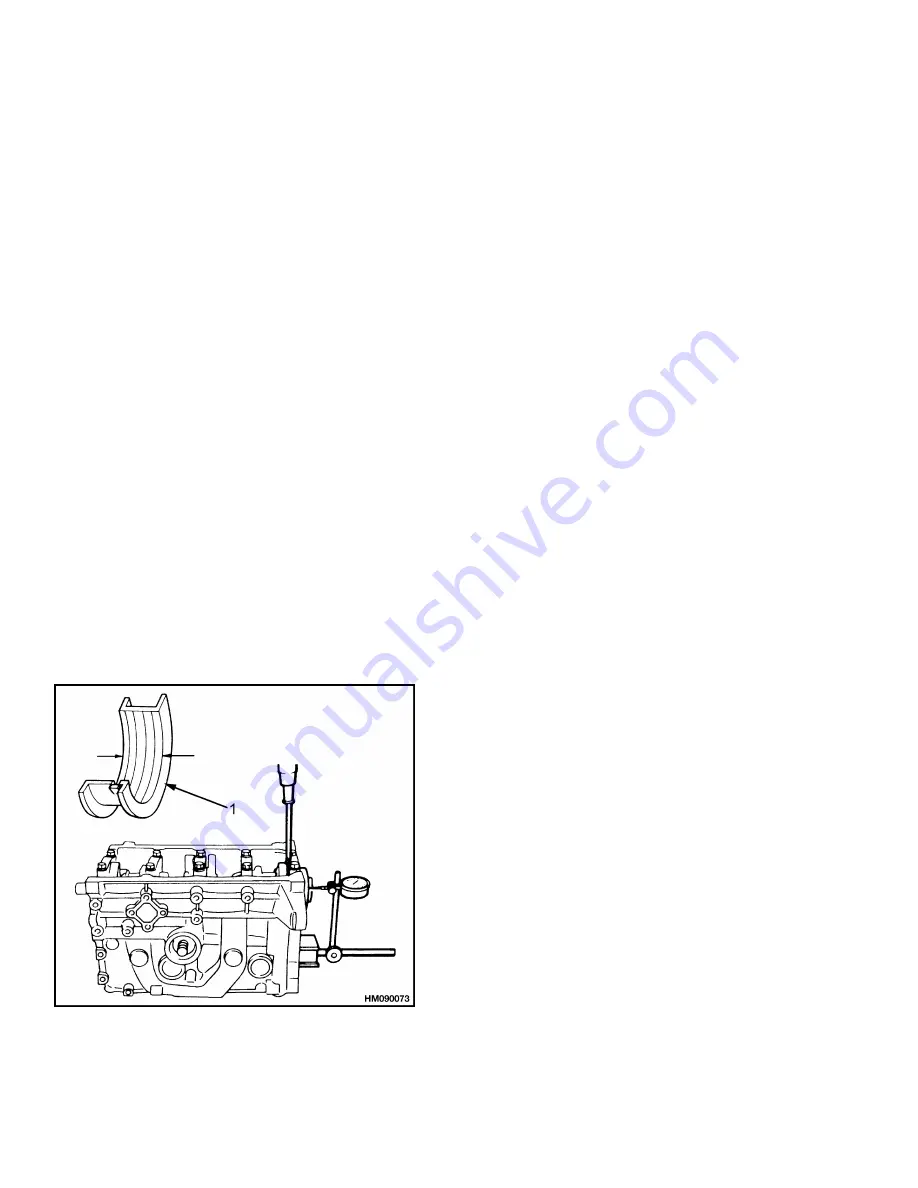

2.

To inspect main bearings for wear, measure clear-

ance between main bearings and crankshaft. See

Figure 28.

a.

Install crankshaft in cylinder block.

10

Summary of Contents for GDP16-20AF

Page 37: ......