Pistons and Connecting Rods Repair

600 YRM 496

1.

F MARK

2.

OIL PORT

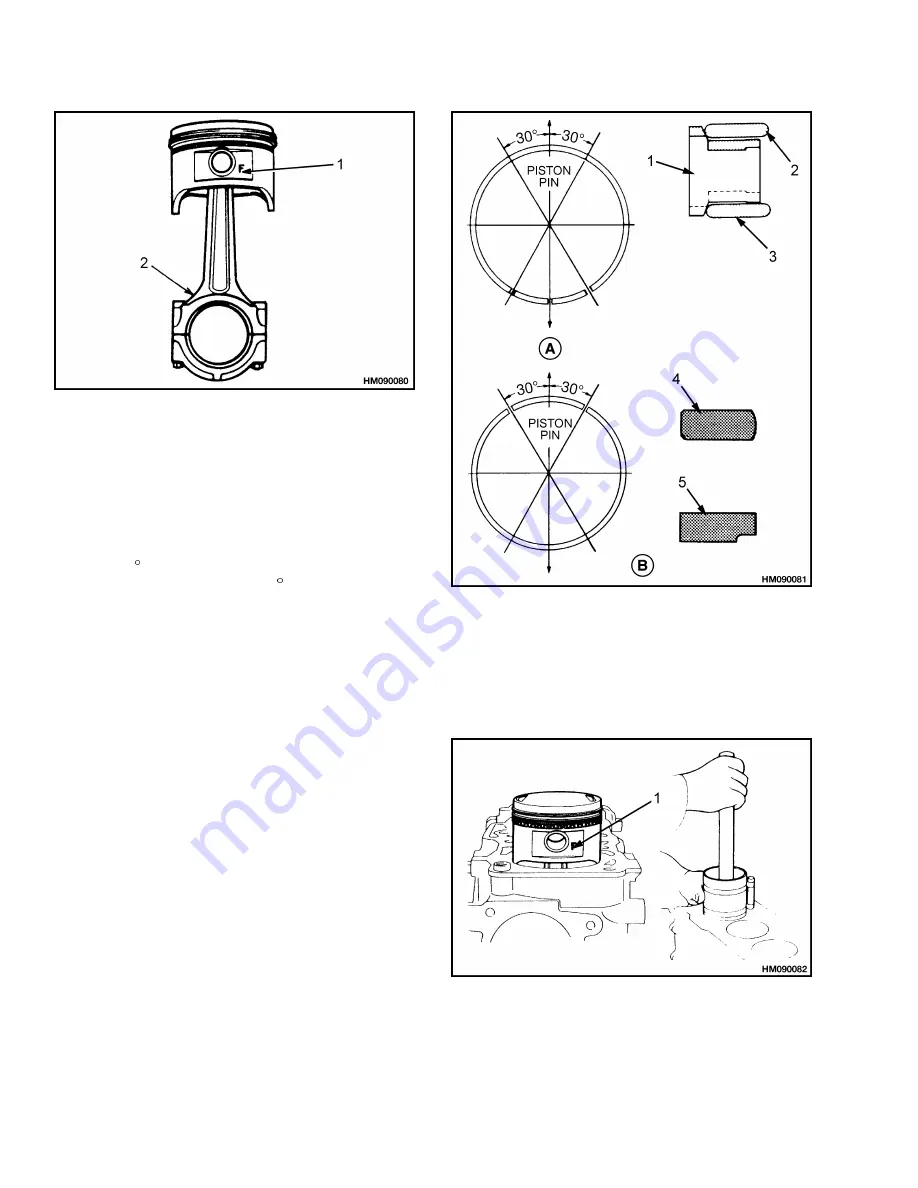

Figure 33. Connecting Rod and Piston

3.

Install piston rings on pistons. During installation,

writing on each piston ring must be toward top of

piston. Check that rings rotate freely. Then put

ends of rings in positions shown in Figure 34. Make

sure ends of upper and lower oil control rings are

each 30 from piston pin. Also make sure that top

and second rings are each 30 from piston pin. Lu-

bricate rings with engine oil.

4.

Apply clean engine oil to piston assembly. Install

bearings for connecting rods. Install piston into cor-

rect cylinder, making sure F is toward front (timing

belt end) of engine. See Figure 35.

5.

Apply clean engine oil to bearing. Then install each

cap to correct connecting rod. During installation of

caps, make sure to align identification marks that

were made during disassembly. Tighten nuts for

caps to 51 to 56 N•m (38 to 41 lbf ft).

A. OIL CONTROL RING

B. TOP AND SECOND RINGS

1.

EXPANDER RING

2.

OIL RING (UPPER)

3.

OIL RING (LOWER)

4.

TOP RING

5.

SECOND RING

Figure 34. Piston Rings

1.

F MARK

Figure 35. Piston Installation

14

Summary of Contents for GDP16-20AF

Page 37: ......