600 YRM 496

Crankshaft and Main Bearings Repair

1.

REAR OIL SEAL

SURFACE

2.

CONNECTING

ROD JOURNALS

3.

MAIN BEARING

JOURNALS

4.

FRONT OIL SEAL

SURFACE

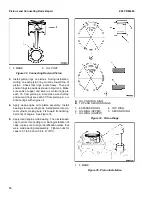

Figure 27. Crankshaft Inspection

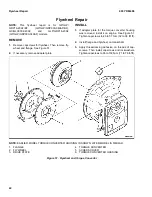

b. Put plastic gauge material on journals and in-

stall main bearing caps. Tighten capscrews for

bearing caps to 84 to 90 N•m (62 to 66 lbf ft).

c.

Remove bearing caps. Plastic gauge material

will adhere to journals or bearing caps.

d. Use graduations on scale to measure width of

plastic gauge material at its widest point.

Correct clearance is 0.031 to 0.049 mm

(0.0012 to 0.0019 in.).

If any clearance is

greater than specification, replace all main

bearings.

1.

PLASTIC GAUGE

MATERIAL

2.

SCALE

Figure 28. Main Bearings Clearance Check

INSTALL

1.

Clean areas of cylinder block around main bear-

ings. Carefully install bottom half of new main bear-

ings if necessary. Lubricate bearings with clean en-

gine oil.

2.

Install crankshaft.

3.

Install top half of main bearings in caps and lu-

bricate with oil. Use identification marks to install

main bearing caps in correct locations.

Tighten

capscrews for main bearing caps to 84 to 90 N•m

(62 to 66 lbf ft).

4.

Install pistons and connecting rods as described in

Pistons and Connecting Rods Repair.

5.

Make sure O-ring is in oil pump housing. Lubricate

oil seal with engine oil. Use adhesive sealant to

install housing to cylinder block. Make sure there is

no sealant in oil port. Tighten M10 capscrews to 38

to 53 N•m (28 to 39 lbf ft). Tighten M8 capscrews

to 19 to 26 N•m (14 to 19 lbf ft).

6.

Lubricate surfaces of oil seal with engine oil. Use

press to install oil seal in rear cover. Install align-

ment pin in cylinder block.

7.

Install gasket and rear cover. See Figure 29. Make

sure dowel pin is installed. Tighten capscrews to 8

to 12 N•m (6 to 9 lbf ft). Cut off part of gasket that

extends past bottom of cylinder block.

11

Summary of Contents for GDP16-20AF

Page 37: ......