600 YRM 496

Oil Pump Repair

Cylinder Block Repair

1.

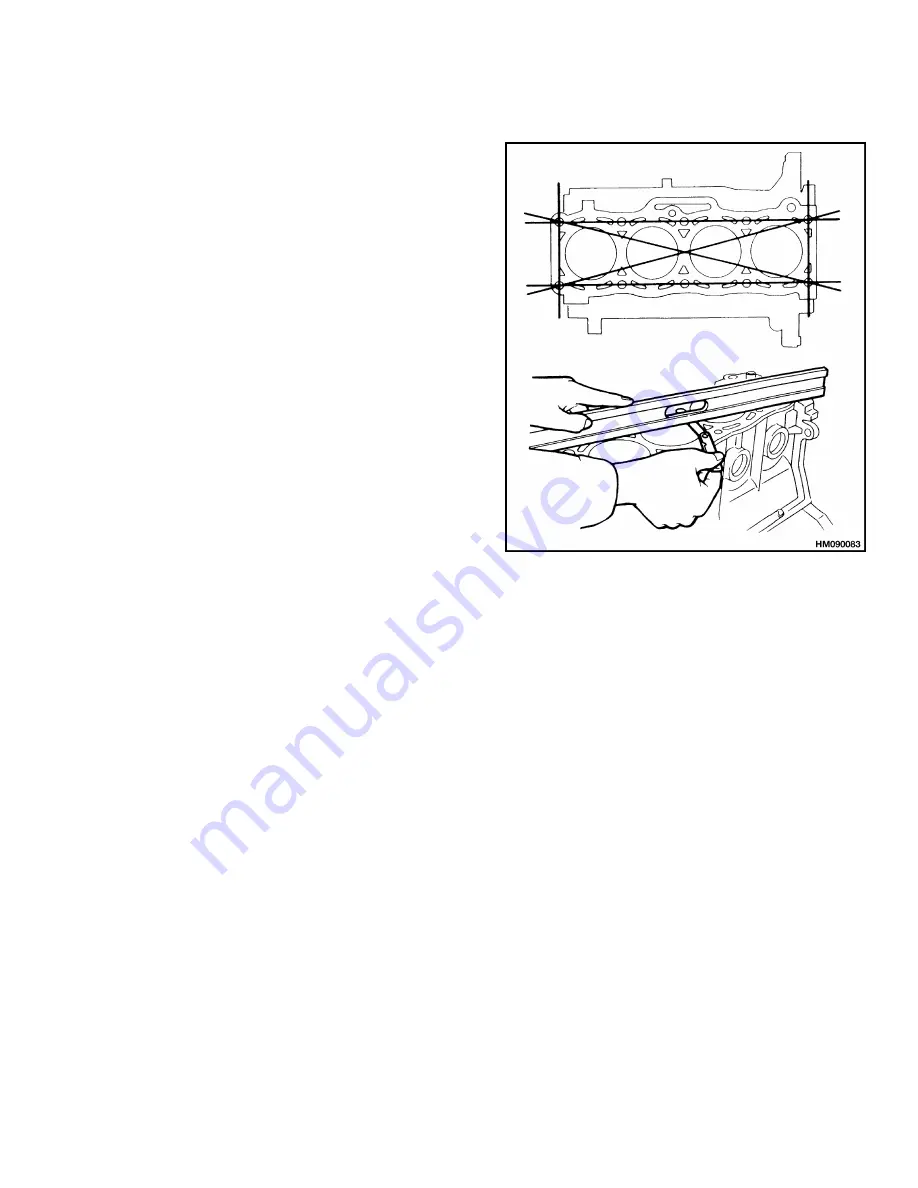

After cylinder block is cleaned, check its surface for

distortion. See Figure 36.

If amount of distortion is greater than 0.15 mm

(0.0059 in.), grind surface of cylinder block. Max-

imum amount of correction permitted is 0.20 mm

(0.008 in.).

2.

Check cylinder bores for wear and damage. Mea-

sure each bore.

Correct dimension is 86.00 to

86.019 mm (3.3858 to 3.3866 in.).

Wear limit

above this dimension is 0.015 mm (0.001 in.).

Repair cylinder block or use bigger pistons as nec-

essary.

Figure 36. Cylinder Block Insepction

Oil Pump Repair

Before removing oil pump, replace sending unit with

pressure gauge and check oil pressure. Minimum oil

pressure at governed rpm is approximately 275 kPa

(40 psi). If pressure is less than specification, oil pump

or engine bearings need repair.

REMOVE

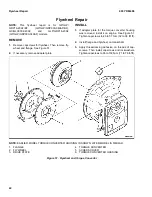

1.

Remove bracket for cooling fan.

2.

Remove upper and lower timing belt covers. See

Figure 37.

3.

Loosen capscrews for timing belt tensioner and re-

move spring. Remove capscrews and timing belt

tensioner.

4.

Use chalk to mark direction of rotation of timing belt.

See Figure 38. Remove timing belt.

5.

Remove six capscrews and plate from crankshaft

pulley. Remove six capscrews that hold crankshaft

shaft pulley to timing pulley.

6.

Remove capscrew from timing pulley. Install spe-

cial tool on crankshaft to remove timing pulley. Ro-

tate tool until it touches the front of crankshaft. Hit

tool with hammer to loosen timing pulley. Remove

pulley, dowel pin, and tapered ring. Remove tool.

7.

Remove capscrews that hold oil pan to cylinder

block. Remove oil pan.

8.

Remove capscrews that hold front cover (pump

housing) to cylinder block. Remove front cover and

oil pump assembly.

1.

UPPER TIMING BELT COVER

2.

LOWER TIMING BELT COVER

Figure 37. Timing Belt Covers

Figure 38. Timing Belt

DISASSEMBLE

1.

Remove screws and pump cover. See Figure 39.

15

Summary of Contents for GDP16-20AF

Page 37: ......