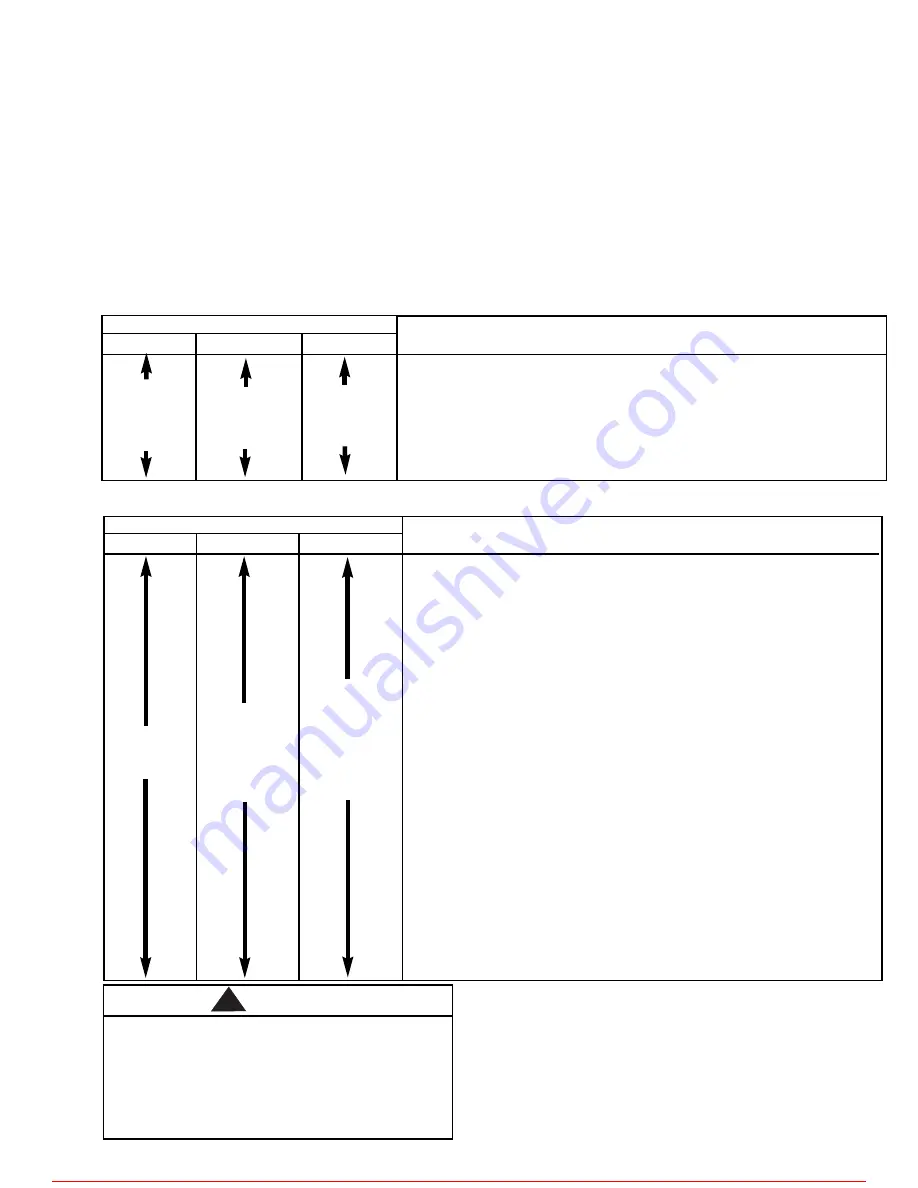

Minimum Inspection Schedule

Frequent Inspections

: These inspections are

visual examinations by the operator or other des-

ignated personnel. Records of such inspections are

not required. The frequent inspections are to be

performed monthly for normal service, weekly to

monthly for heavy service, and daily to weekly for

severe service and they should include those items

listed in Table 1.

Periodic Inspections:

These inspections are visu-

al inspections of external conditions by an appoint-

ed person. Records of periodic inspections are to

be kept to provide the basis for continuing evalua-

tion of the condition of the hoist.

Periodic inspections are to be performed yearly for

normal service, semi-annually for heavy service and

quarterly for severe service and they are to include

those items listed in Table 2.

Any parts that are deemed unserviceable are to be

replaced with new parts before the unit is returned

to service. It is very important that the unserviceable

parts be destroyed and properly disposed of to

prevent their possible future use as a repair item.

TYPE OF SERVICE

Normal

Heavy

Severe

TYPE OF SERVICE

Normal

Heavy

Severe

ITEM

a) Brake for evidence of slippage.

b) Hooks for damage, cracks or excessive throat opening, latch

engagement and latch operation - see page 6.

c) Inspect load chain for adequate lubrication, signs of wear,

damaged links or foreign matter - see page 6.

d) Inspect reeving of the load chain to make sure it is proper -

see page 6.

ITEM

a) Frequent inspections per Table 1.

b) External evidence of loose bolts or nuts.

c) External evidence of worn, corroded, cracked or distorted hook

blocks, suspension bolts, gears, pins, bearings, hand chain wheel,

frames, hoist hanger, load chain guide, hook block pin on 1/4

thru 2 ton units, dead end pin on 3, 4, 8 and 10 ton units, and

dead end screw on 5 and 6 ton units.

d) External evidence of damage to hooks, hook nuts or collars and

hook nut or collar pins.

e) External evidence of damage or excessive wear of the pockets of

the liftwheel, handwheel, hook block sheaves and hanger sheaves.

f) External evidence of worn, glazed or oil contaminated friction

discs, scoring of handwheel hub, ratchet, and friction hub.

g) External evidence of worn pawl and ratchet teeth; corroded,

stretched or broken pawl spring.

h) Supporting structure and trolley, if used, for continued ability to

support the imposed loads.

i)

Inspect trolley wheels for external wear on the tread and flange,

and for wear on the internal bearing as evidenced by looseness

on the stud.

j)

Warning label and tube for absence or illegibility.

k) Check for proper connections at dead end and loose end of load

chain.

l)

Load Limiter components for corrosion.

Monthly

W

eekly

to

Monthly

Daily

to W

eekly

Table 1 Minimum Frequency Inspections

Table 2 Minimum Periodic Inspections

Y

early

Twice a Y

ear

Every 3 Months

Any deficiencies are to be corrected before returning the

hoist to service. Operating a hoist with worn or damaged

parts or a malfunctioning hoist may result in serious

personal injury to the operator, nearby personnel and/or

property damage.

Also, the external conditions may show the need for dis-

assembly to permit a more detailed inspection which, in

turn, may require the use of nondestructive type testing.

PREVENTIVE MAINTENANCE

In addition to the above inspection procedure, a preventive

maintenance program should be established to prolong

the useful life of the hoist and maintain its reliability and

continued safe use. The program should include the

periodic inspections with particular attention being paid

to the lubrication of various components using the

recommended lubricants.

5

WARNING

!

For more information contact: Sievert Crane and Hoist, (708) 771-1600, parts@sievertelectric.com, www.sievertcrane.com