WARNING

DO NOT make repairs or adjustments unless you

have been properly trained and authorized to do

so. Improper repairs and adjustments can create

dangerous operating conditions. DO NOT operate

a lift truck that needs repairs. Report the need for

repairs to your supervisor immediately. If repair is

necessary, attach a DO NOT OPERATE tag to the

control handle and disconnect the battery.

Disconnect the battery and discharge the internal

or external capacitors before opening any com-

partment covers or inspecting or repairing the

electrical system. DO NOT place tools on top of

the battery. If a tool causes a short circuit, the high

current flow from the battery can cause personal

injury or property damage.

Some checks and adjustments are performed with

the battery connected. DO NOT connect the bat-

tery until the procedure instructs you to do so.

Never wear jewelry or other metallic items on your

fingers, arms, or neck when working near electri-

cal components. Metal items can accidentally

make an electrical connection and cause injury.

Before performing any tests or adjustments, block

the lift truck to prevent unexpected movement.

The capacitors in the transistor controllers can

hold an electrical charge after the battery is dis-

connected. To prevent an electrical shock and per-

sonal injury, discharge the internal or external ca-

pacitors before inspecting or repairing any compo-

nent in the electrical compartments. Make certain

that the battery has been disconnected.

DO NOT short across the motor controller termi-

nals with a screwdriver or jumper wire.

CAUTION

To avoid controller damage, always disconnect the

battery, discharge the internal or external capaci-

tors, and never put power to the controller while

any power wires are disconnected. Never short

any controller terminal or motor terminal to the

battery. Make sure to use proper procedure when

servicing the controller.

1.

Move the lift truck to a safe, level area and

completely lower the forks. Turn the key switch to

the

OFF

position and attach a

DO NOT

OPERATE

tag to the control handle. Block the

drive wheel to prevent unexpected movement.

2.

Disconnect the battery power cable connector

from the truck connector located on the top-left

side of the frame. Pull the battery cable connector

handle to separate the battery connector from the

truck connector.

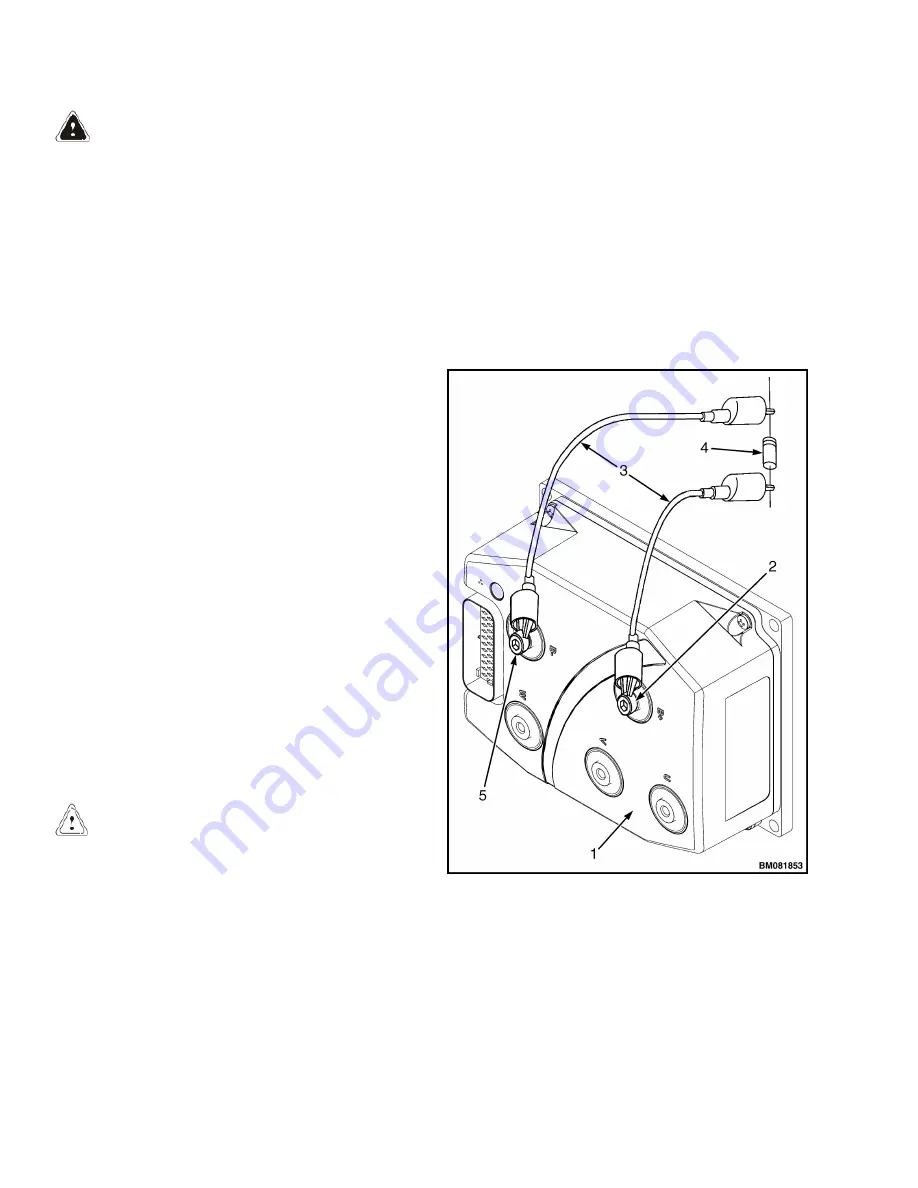

3.

Remove the operator compartment cover.

4.

Discharge the internal or external capacitors in

the controllers by connecting a 200-ohm, 2-watt

resistor across the controller B(+) and B(-)

terminals of the combination controller. Remove

the resistor after discharging the capacitors. See

Figure 9030-03-1.

1. TRACTION CONTROLLER

2. POSITIVE CONNECTION

3. INSULATED JUMPER WIRES

4. 200-OHM, 2-WATT RESISTOR

5. NEGATIVE CONNECTION

Figure 9030-03-1. Discharging the Capacitors

General Maintenance and Diagnostic Data

ELECTRICAL SYSTEM

Check the Service Manual section in Yale Axcess Online for possible updates and check pertinent Bulletins

9030-03-2

Confidential/Proprietary - Do Not Copy or Duplicate

Summary of Contents for MPB045VG

Page 1: ...Maintenance CONTROLLER DIAGNOSTICS MPB045VG A245 PART NO 550095689 9000 YRM 1671 ...

Page 4: ......

Page 6: ......

Page 10: ...9030 4 ...

Page 24: ...NOTES 9030 03 14 ...

Page 83: ......

Page 84: ...9000 YRM 1671 10 19 9 15 1 15 12 14 10 14 4 14 ...