88

Mtrac endless winch

3.4 Yale control systems

A) Contactor control

Access for the mains cable and the control cable is provided on the

contactor control system. Always make sure that the control cable is

provided with a strain relief arrangement.

Important:

This control system is only suitable for stationary operation

B) Control system with phase sequence monitoring

A CEE-16A plug is provided on the control system with phase sequence

monitoring for power supply to the endless winch. The control cable is

connected by means of a cable union. Always make sure that the control

cable is provided with a strain relief arrangement.

Motor and, if required, emergency-stop limit switch can be connected

to the control system by means of plug connectors.

C) Control system for two endless winches

A CEE-16A plug is provided on the control system for two endless

winches for power supply to the endless winches. The control elements

for operating the endless winch and the emergency-stop pushbutton are

arranged on the door of the switching cabinet of the control system. The

main switch of the endless winch is also located on the control system.

The two motors and, if required, emergency-stop limit switches can be

connected to the control system by means of plug connectors.

3.5 Power supply

The operating company is responsible for the connection of the Yale endless

winches. It is essential that the circuit diagrams included in the supply be

taken into account.

Complete the electrical connection of the winches in ac-

cordance with EN 60204-1or EN 60204-32. Always pull

the power plug before opening any control system.

1) Always check whether mains voltage and motor voltage match

Three-phase current: 400 V (3P+N+PE), 50 Hz with 16 A CEE plug

2) For min. cross sections of the supply cables, comply with the following

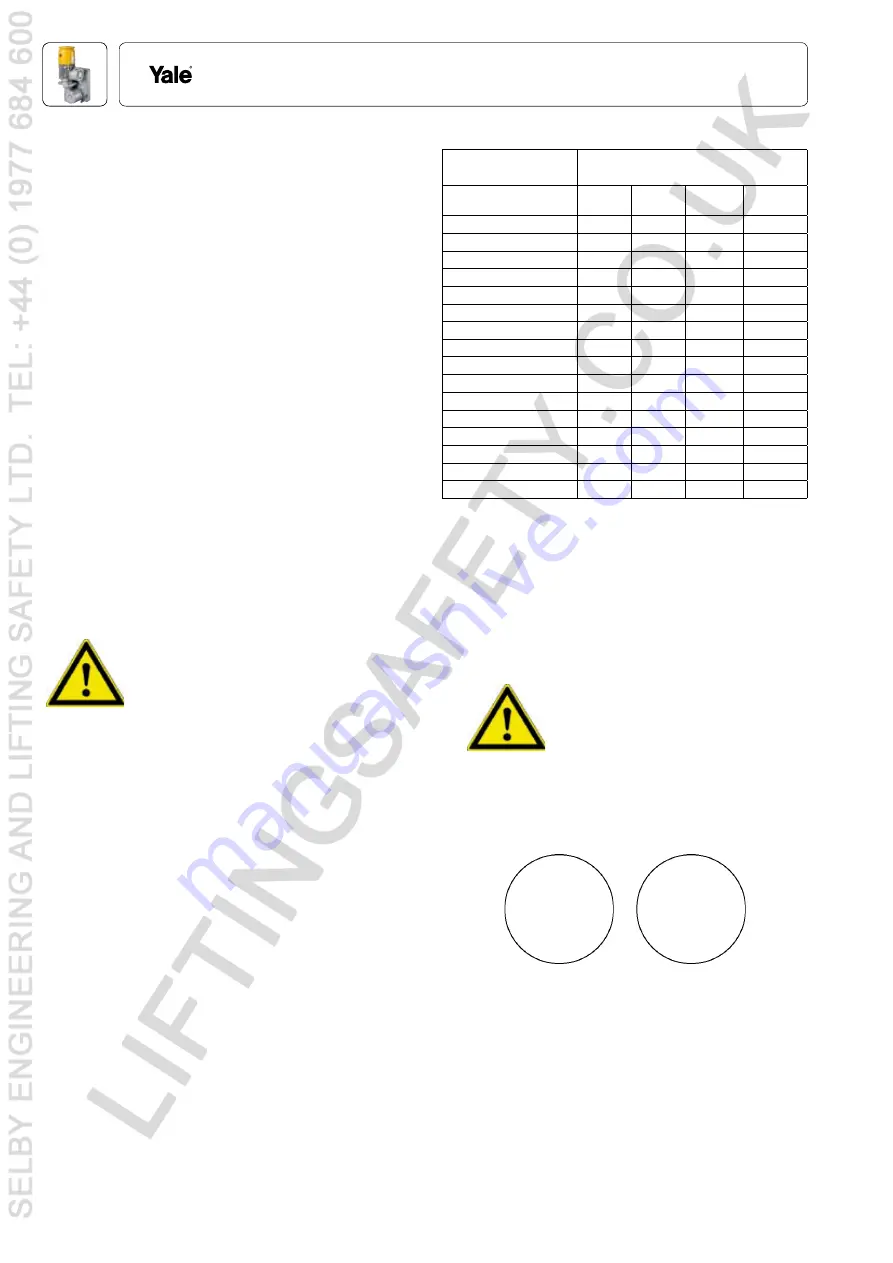

table!

Type of winch

Required cable cross section in mm

2

for cable lengths up to

25 m

50 m

100 m

200 m

1x YMT/F 5-9-M8

1,5

1,5

1,5

1,5

2x YMT/F 5-9-M8

1,5

1,5

1,5

2,5

1x YMT/F 5-18-M8

1,5

1,5

1,5

2,5

2x YMT/F 5-18-M8

1,5

2,5

4,0

6,0

1x YMT/F 6-9-M8

1,5

1,5

1,5

1,5

2x YMT/F 6-9-M8

1,5

1,5

1,5

2,5

1x YMT/F 6-18-M8

1,5

1,5

1,5

2,5

2x YMT/F 6-18-M8

1,5

2,5

4,0

6,0

1x YMT/F 8-9-M8

1,5

1,5

1,5

1,5

2x YMT/F 8-9-M8

1,5

2,5

4,0

6,0

1x YMT/F 8-18-M8

1,5

1,5

1,5

2,5

2x YMT/F 8-18-M8

1,5

2,5

4,0

10,0

1x YMT/F 10-9-M9

1,5

1,5

1,5

1,5

2x YMT/F 10-9-M9

1,5

2,5

4,0

6,0

1x YMT/F 10-18-M9

1,5

2,5

4,0

10,0

2x YMT/F 10-18-M9

1,5

4,0

10,0

16,0

4) Always use heavy rubber cables with strain relief!

5) Always use a cable sleeve or similar, if the drooping cable is longer

than 30 m!

6) If a generator is to be used for power supply, it must have at least 3

times the rated output of the winch motor.

3.6 Fitting the wire ropes

A) Preparation

Caution when handling wire ropes:

Always wear protective gloves.

1) Only use original Yale wire ropes.

Example for the marking of the Yale 8.4 mm rope

(tag on the thimble):

Front

Rear

2) Make sure that the wire rope has the correct diameter and an ap-

propriate length.

3) Always unwind the wire rope orderly and without twisting (by also

turning the winder). Otherwise the wire rope may be rendered unus-

able as a consequence of rope slings.

CMCO

4269-10

8

20 M

Summary of Contents for Mtrac YMT-M Series

Page 18: ...18 18 Mtrac endless winch ...

Page 19: ...19 19 Mtrac endless winch ...