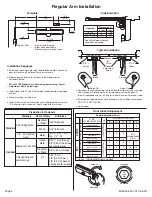

Regular Arm Installation

Page 2

80-9350-2527-010 (06-09)

6

(152)

1-3/4

(44.5)

1-1/4

(32)

3/4

(19.1)

9-1/16

(230.2)

1/2

(12.7)

A

Template

Hinge or Pivot

C

L

• Do not scale drawing.

• Right hand door shown.

• Dimensions are in inches (mm).

Installation Sequence

!

!

!

!

!

Select door opening angle using template above. Mark 4 holes on

door for closer and 2 holes on frame for arm shoe.

Prepare door and frame for fasteners See “Preparation for

Fasteners” below.

Install closer with “S” and “L” adjustment valves toward hinge edge

of door.

Mount arm shoe to frame face.

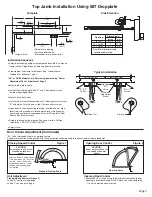

Install main arm onto closer pinion shaft, indexing main arm mark

“S” with pinion flat as shown at right. Fasten with arm screw.

!

251 or 251BF Models Only. Set closing power using “Power

Adjustment Chart” below right.

Side Elevation

Opening

To 100°

101° to 120°

121° to 180°

Dimension A

inches

7

6

3-1/2

mm

178

152

89

* Door/Wall/Hardware/Jamb

conditions permitting

Typical Installation

Right Hand Door

Left Hand Door

Optional

“BC”

Valve

“S” & “L”

Valves

Power

Adjustment

Screw

Preload

Preload

Pinion Flat

!

!

Open door to allow connecting rod to be inserted into arm slide. Insert rod

and close door. Preload main arm by rotating away from hinge until

forearm is perpendicular (at 90° angle) to door. Secure with forearm screw.

Screw pinion cap onto pinion shaft by hand or with a Phillips screw driver -

DO NOT OVER TIGHTEN.

Adjust closer.

!

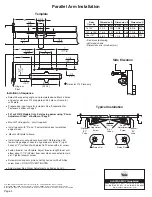

Door Closer Adjustment

Power Adjustment Chart

DOOR

INTERIOR

INTERIOR

EXTERIOR

EXTERIOR

251BF

251

TYPE

OF INSTALLATION

REGULAR ARM

TOP JAMB

PARALLEL ARM

REGULAR ARM

TOP JAMB

PARALLEL ARM

REGULAR ARM

REGULAR ARM

TOP JAMB

PARALLEL ARM

TOP JAMB

PARALLEL ARM

MAXIMUM DOOR SIZE

34”

(0.85 m)

36”

(0.9 m)

40”

(1 m)

44”

(1.1 m)

48”

(1.2 m)

1

2

5

8

2

3

3

5

1

2

6

9

4

5

5

7

2

3

8

12

6

7

7

10

3

4

9

10

10

14

3

5

11

13

13

16

*18 -360° TURNS MAXIMUM AVAILABLE

*

FULL 360

TURNS

OF PO

WER ADJUSTMENT

SHAFT

o

NOT

RECOMMENDED

USE 251

Increase

Decrease

1/8”

Hex

Key

Increase

Decrease

FULL 360

TURNS

OF PO

WER ADJUSTMENT

SHAFT

o

“S” & “L”

Valves

1

2

3

4

Z

Y

S

Pinion Flat

1

2

3

4

Z

Y

S

9/32” (7 mm);

3/8” (9.5 mm) dia. x

3/8” (9.5 mm) deep on

door opposite to closer

Standard

Optional

Through-bolts and

grommet-nuts

All

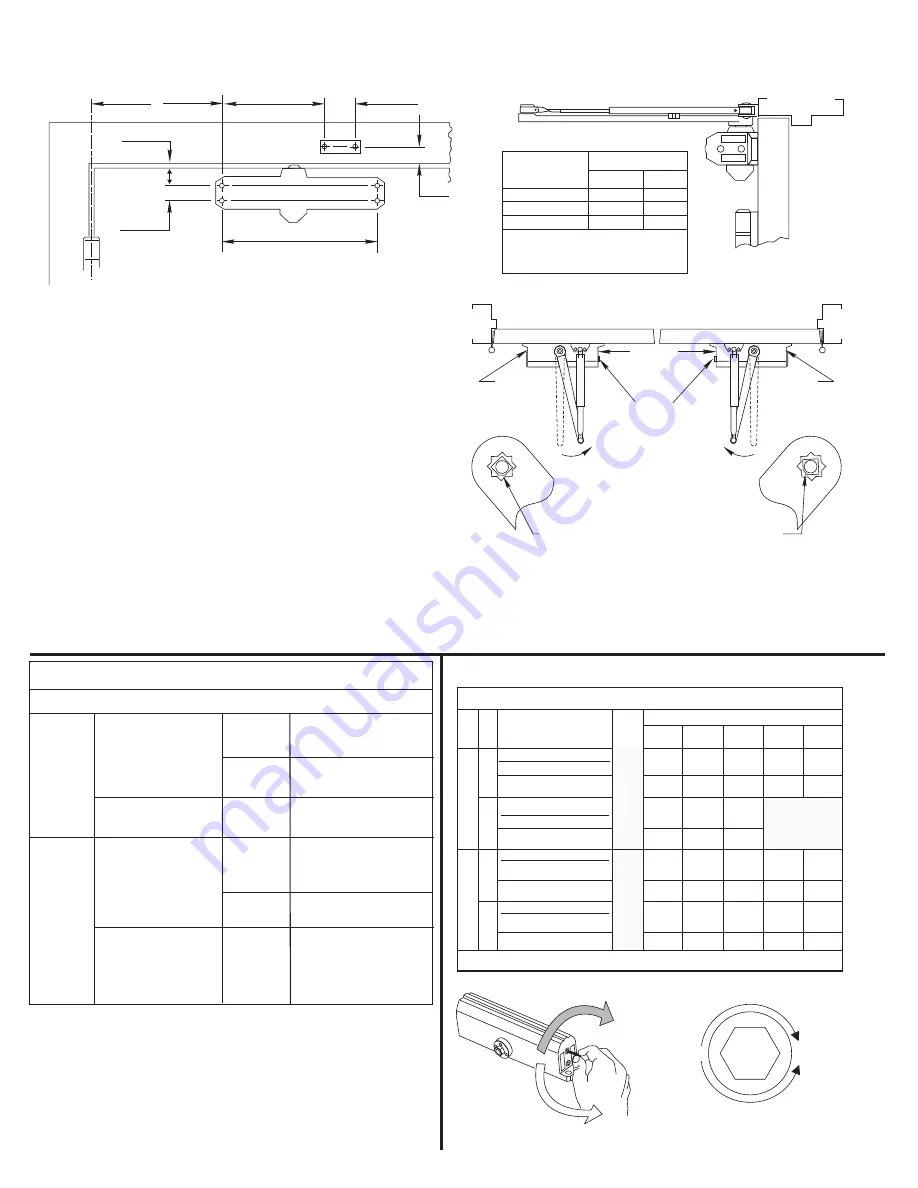

Preparation for Fasteners

Door or Frame

Fasteners

Drill-Sizes

Self-Drilling Screw

Wood

3/16” (4.30 mm)

1/4” - 20 machine

screw

Metal

Drill: #7 (0.201” dia.)

Tap: 1/4” - 20

Sleeve nuts and bolts

Hollow

Metal

9/32” (7 mm) through;

3/8” (9.5 mm) door face

opposite to closer

Aluminum

or Wood

3/8” (9.5 mm) through

Aluminum

or Metal

No drill required