7

8

SINGLE & DOUBLE GIRDER TOP-RUNNING BRIDGES

WITH INDIVIDUAL MOTOR DRIVEN

END TRUCKS

P/N: 11532620 REV. AA

September 2018

WARNING

Never leave an unattended load hanging from the crane.

Load must be safely placed on floor prior to the crane

operator leaving the controls.

When crane is not in use, during the work period, it should be

parked in a safe location, such as the end of the bay or a location

that will not interfere with the movement of people, materials and

equipment. Turn power off to the mainline contactor of the crane.

Store the pendant against a wall or column to prevent damage from

traffic. At the end of the work period or day, park crane as described

herein and turn power off at both disconnects.

RESPONSIBILITY FOR SAFE OPERATION

Each crane operator should be held directly responsible for the safe

operation of his crane. The crane operator should STOP the crane

and refuse to handle loads when:

1. there is any doubt as to SAFETY.

2. any unusual vibrations or sounds are noticed before or when

starting the lift or traverse motions.

3. there are arguments or disagreements with the floor man or

hitchers.

4. the operator feels ill or is not alert.

Overhead cranes are subject to four levels of inspection; Initial, Pre-

Shift, Frequent and Periodical in accordance with the latest editions

of ANSI/ASME B30.2, B30.17 and CMAA 78. These inspections are

necessary to ensure the equipment is safe for use and operating at

its required performance level. Inspection criteria described herein

are general requirements. Specific inspection criteria will be based

on the options and accessories provided with your crane. Refer to

the manufacturer’s maintenance manual for the hoist/trolley and its

specific inspection criteria.

INITIAL INSPECTION

New, re-installed, altered, repaired and modified cranes shall be

inspected prior to initial use. Inspection of all altered, repaired or

modified cranes may be limited to the provisions affected by the

work as determined by a qualified crane technician. Inspections shall

include, but not limited to, clearances, operating speeds, lubrication,

control settings, safety devices, etc. Refer to START UP and PRE-

OPERATIONAL INSPECTION elsewhere in this manual.

PRE-SHIFT INSPECTION

A pre-shift inspection shall be performed by the crane operator or

designated person at the beginning of each shift, or the first time

the crane is used during each shift. This is a visual and operational

inspection to ensure the equipment is in good working order. Items

to be checked include limit switches, brakes, electrical equipment

and all safety devices. Crane is to be operated without a load to

check for any unusual sounds, vibrations, or anything that may be

apparently wrong. Any discrepancies or suspected discrepancies

shall be immediately reported to crane operator’s supervisor. Below

is a check list which can be used for this inspection.

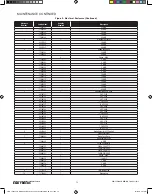

PRE-OPERATION INSPECTION CHECKLIST

Tagged Crane

or Hoist

Check that crane or hoist is not tagged with an

out-of-order sign.

Control Devices

Test run that all motions agree with control

device markings.

Brakes

Check that all motions do not have excessive

drift and that stopping distance is normal.

Hook

Check for damage, cracks, nicks, gouges,

deformations of the throat opening, wear on

saddle or load bearing point, and twist. Refer

to the manual furnished by the original crane

manufacturer.

Hook Latch

If a hook latch is required, check for proper

operation.

Wire Rope

Check for broken wires, broken strands, kinks,

and any deformation or damage to the rope

structure.

Hoist Chain

Check for cracks, nicks, gouges, wear and

stretch-check that the chain is in the upper and

lower sprockets and in the chain guide.

Reeving

Check that the wire rope is properly reeved

and that rope parts are not twisted about each

other.

Limit Switches

Check that the upper limit device stops the

lifting motion of the hoist load block before

striking any part of the hoist or crane.

Oil Leakage

Check for any sign of oil leakage on the crane

and on the floor beneath the crane.

Unusual Sounds

Check for any unusual sounds from the crane

or hoist mechanism while operating the crane

or hoist.

Warning and

Safety Labels

Check that warning and other safety labels are

not missing and are legible.

Housekeeping

and Lighting

Check area for accumulation of material to

prevent tripping or slipping. Also check area for

poor lighting.

OPERATING PRECAUTIONS

INSPECTION

CMK_12322 Yale Rotating Axle End Truck Parts 11532619-REV AD_mec.indd 8

10/16/18 2:07 PM